The blow moulding process

Summary

TLDRThe video explains the plastic blow molding process used to create hollow containers like jars and bottles. It starts with raw plastic granules, which are melted and molded into a paracin, then blown into the shape of a mold using pressurized air. After cooling and solidifying, excess plastic is removed and sent back into a closed-loop system for recycling. Containers are tested for leaks and then packaged for product manufacturers. The process ensures efficiency, minimal waste, and high-quality containers ready for use.

Takeaways

- 😀 Blow molding is the most popular method used for producing hollow plastic containers.

- 😀 Various raw materials are used in blow molding depending on the container's application and performance requirements.

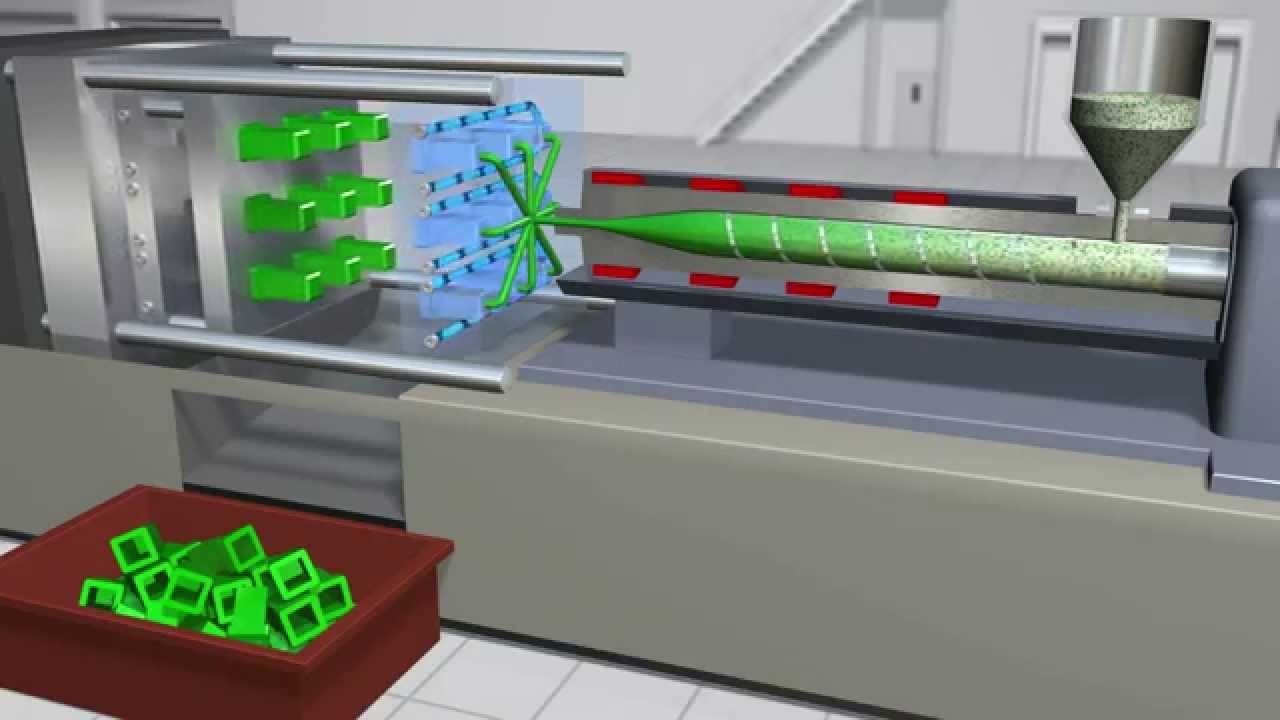

- 😀 Plastic granules are fed into a heated barrel, where they are melted and mixed with a colorant called master batch.

- 😀 A molten tube of plastic, known as a paracin, is extruded and cut with a hot blade.

- 😀 The paracin is captured by a water-cooled mold, and pressurized air is blown into it to shape the container.

- 😀 Once cooled and solidified, the mold opens, and the newly formed container is ejected.

- 😀 Excess plastic, called the tail, is removed from the container and returned to the beginning of the process for reuse in a closed-loop system.

- 😀 The container undergoes trimming to remove additional excess plastic known as the lust head.

- 😀 Both the tail and lust head are collected and added back into the closed-loop system for recycling.

- 😀 Containers are tested for leaks by pressurizing them with air; if a leak is detected, the container is rejected and sent back into the system for recycling.

- 😀 Once all excess plastic is removed and quality checks are completed, the containers are ready for packaging and distribution to manufacturers.

Q & A

What is plastic blow molding used for?

-Plastic blow molding is primarily used to produce hollow containers such as jars and bottles.

What raw material is used in the blow molding process?

-The raw material used is plastic in granular form, which is fed into the feed barrel. The material can vary depending on the container's application and expected performance.

How does the plastic material get processed in the machine?

-The granular plastic is heated in a feed barrel to melt it, and a colorant called master batch is evenly dispersed into the material.

What is a paracin in blow molding?

-A paracin is a molten tube of plastic that is extruded from the machine head and cut with a hot blade during the blow molding process.

What role does the blowing nozzle play in blow molding?

-The blowing nozzle is inserted into the paracin, and pressurized air is blown into it, forcing the plastic to take the shape of the mold.

How does the mold contribute to the blow molding process?

-The mold captures the molten paracin, and once the air is blown into it, the hot plastic takes the shape of the mold, which solidifies as it cools.

What happens to the excess plastic during blow molding?

-Excess plastic, known as the tail, is removed by a de-flasher, then recycled by being ground and reused in a closed-loop system.

What is the purpose of the trimmer in the process?

-The trimmer removes any remaining excess plastic called the 'lust head,' which is also added to the closed-loop system for reuse.

How are the bottles tested for defects?

-The bottles undergo a leak test where air is blown into the bottle. If there are any leaks, the air will escape, and the bottle will be rejected.

What happens to rejected bottles after the leak test?

-Rejected bottles are sent back into the closed-loop system for recycling and reuse.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)