TEKNIK UJI KUAT TEKAN BETON | ANAK TEKNIK

Summary

TLDRThis video tutorial demonstrates the process of testing the compressive strength of concrete using a hydraulic testing machine. The procedure involves preparing concrete samples in cylindrical molds, measuring their dimensions, cleaning them, and conducting the test by gradually applying pressure until the samples fracture. The video covers steps including sample weight measurement, ensuring proper machine setup, and recording the maximum pressure at failure. The process is repeated for multiple samples, and results are compiled for analysis. The video also emphasizes the importance of consistency and safety during testing, along with tips for creating detailed reports on test outcomes.

Takeaways

- 😀 The video focuses on the testing technique for concrete compressive strength.

- 😀 The goal of the concrete compression test is to determine the compressive strength of concrete by applying pressure until the test specimen fails.

- 😀 The concrete test specimen is usually cylindrical, with a 15 cm diameter and a height of approximately 30 cm.

- 😀 Each specimen is weighed before testing to ensure accurate measurement and record keeping.

- 😀 Before testing, the specimen is cleaned to remove any dirt or debris, ensuring only the concrete is tested.

- 😀 A hydraulic press is used for the testing, with pressure applied at a constant rate of 2-4 kg per cm² per second.

- 😀 The test continues until the concrete specimen fails, and the maximum load at failure is recorded.

- 😀 Concrete compressive strength testing is typically done at different curing periods, such as 3 days, 7 days, and 28 days.

- 😀 For accurate results, it is recommended to use at least two test specimens to calculate an average result.

- 😀 The failure of each specimen often results in different break patterns, which must be documented for the report.

- 😀 The video also highlights the importance of careful handling and recording during the concrete compressive strength testing process.

Q & A

What is the purpose of the concrete compressive strength test?

-The purpose of the concrete compressive strength test is to determine the concrete's strength by measuring the amount of pressure per unit area that causes the concrete specimen to fail under a specific compressive load applied by a testing machine.

What are the dimensions of the concrete test specimens used in the video?

-The test specimens used in the video are cylindrical with a diameter of 15 cm and a height of 30 cm.

Why is it important to clean the concrete test specimen before testing?

-Cleaning the concrete test specimen is important to remove any dirt or debris that could affect the test results, ensuring that the specimen is in its correct condition for accurate measurement during the compression test.

What equipment is used in the compressive strength test?

-The equipment used in the compressive strength test is a hydraulic testing machine that applies a constant load to the concrete specimen during the test.

How is the compressive load applied during the test?

-The compressive load is applied gradually with a constant rate of increase between 2 and 4 kg per cm² per second until the concrete specimen fails.

What is the significance of the maximum load during the test?

-The maximum load recorded during the test is crucial as it represents the point at which the concrete specimen fails, and this value is used to calculate the compressive strength of the concrete.

How many test specimens should be used for a valid compressive strength test?

-At least two test specimens should be used for a valid compressive strength test to ensure the accuracy and reliability of the results, though three are often used.

Why is it necessary to conduct compressive strength tests at different ages of concrete?

-Compressive strength tests are typically conducted at different ages, such as 3, 7, and 28 days, to assess how the concrete's strength develops over time and to determine its suitability for use in construction projects.

What happens to the concrete specimen during the test as the compressive load increases?

-As the compressive load increases, the concrete specimen gradually deforms and eventually fractures or crushes when the material can no longer withstand the applied pressure.

What should be done after the concrete specimen fails during the test?

-After the concrete specimen fails, the operator must record the maximum load applied during the test and observe the failure pattern, which will then be documented and used to prepare a report on the test results.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

LAB IN YOUR GRASP - KARAKTERISASI MATERIAL BETON : 17 PENGUJIAN KUAT TEKAN BETON

KEREN BANGET NIH !!!!! TUTORIAL PEMBUATAN BETON , PROGRAM STUDI TENIK SIPIL UNIVERSITAS KADIRI 😊🤩

Pemeriksaan Kuat Tekan Kayu

How to determine split tensile strength test of concrete || Laboratory Concrete Test #2

CIVE1265 Concrete lab Part 2

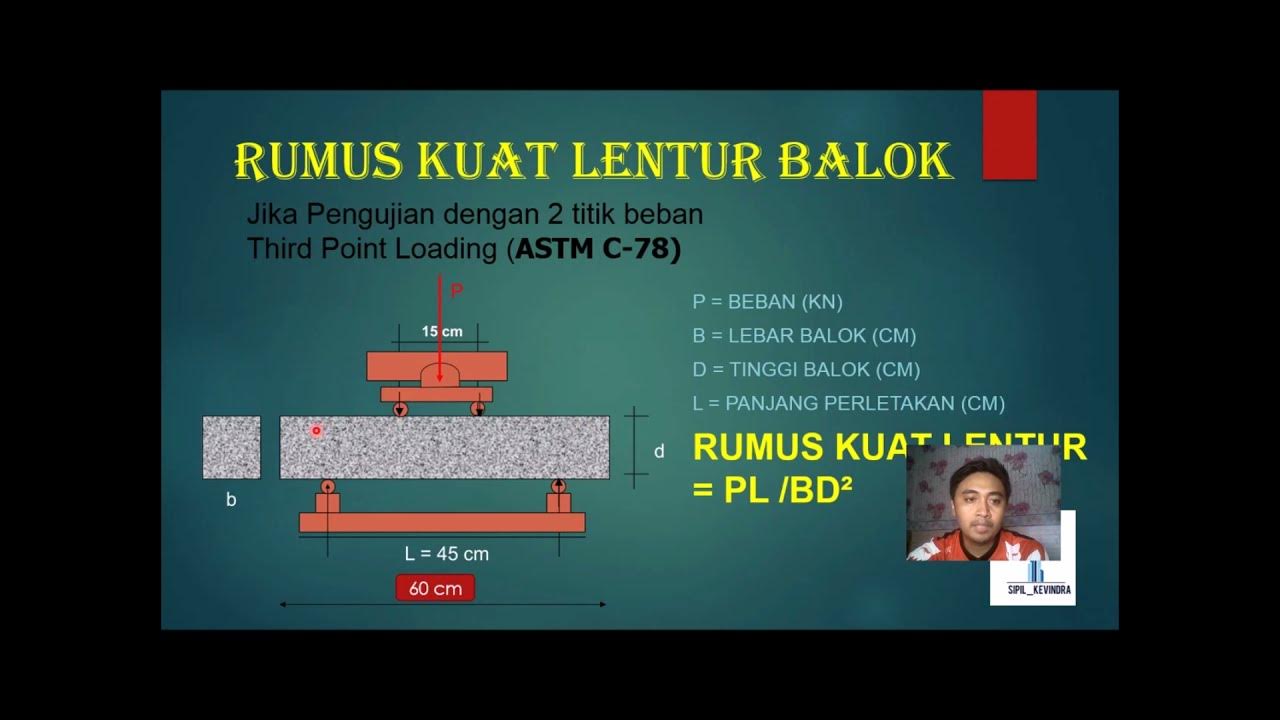

PENGUJIAN TES KUAT LENTUR BETON

5.0 / 5 (0 votes)