CIVE1265 Concrete lab Part 2

Summary

TLDRThe video script details a comprehensive guide on concrete testing, focusing on compressive, split intensity, and flexural testing. It explains the standard sample sizes for different standards, such as Australian and U.S. standards favoring 200mm x 100mm cylinders, while UK and European standards prefer 100mm or 150mm cubes. The script also describes the use of an MTS machine for testing, the setup for split intensity testing with a special frame, and the four-point bending test arrangement. The video provides a practical demonstration of these tests, enhancing understanding of concrete strength evaluation.

Takeaways

- 🗓️ The script describes a process of testing concrete specimens after a curing period of seven days.

- 🏗️ Three types of concrete tests are mentioned: compressive testing, split intensity testing, and flexural (bending) testing.

- 📏 Compressive testing can be conducted on two different sample sizes: 200mm height by 100mm diameter cylinders or cubes of 100mm or 150mm.

- 🌐 There are regional differences in standard sample sizes, with Australia and the U.S. favoring cylinders and the UK and Europe favoring cubes.

- 📊 Compressive strength readings can vary depending on whether cylinders or cubes are used, so it's important to specify the specimen type when presenting results.

- 🔩 The script introduces a larger cylinder with 300mm height and 150mm diameter, which is used for split intensity testing.

- 🔄 Split intensity testing involves applying a horizontal compression load that converts into an axial tensile force, causing the cylinder to split.

- 🛠️ The script mentions the use of an MTS machine for testing, capable of applying up to 3000 Newtons of force, with the possibility of upgrading for higher loads.

- 🔧 A special frame is required for split intensity testing, which is different from the standard compressive testing setup.

- 🔄 The script also discusses four-point bending testing, which requires a specific framework with two points of loading and two roller supports.

Q & A

What types of concrete testing are mentioned in the script?

-The script mentions three types of concrete testing: compressive testing, split intensity testing, and flexural or bending testing.

What are the standard sample sizes for compressive testing according to the script?

-The standard sample sizes for compressive testing mentioned are 200 millimeter height and 100 millimeter diameter cylinders, and 100 or 150 millimeter cubes.

Why might there be different compressive strength values for cylinders and cubes?

-Different compressive strength values for cylinders and cubes may be due to the different shapes and sizes of the samples, which can affect the stress distribution during testing.

What is the purpose of the larger cylinder with 300 millimeter height and 150 millimeter diameter?

-The larger cylinder with 300 millimeter height and 150 millimeter diameter is used for split intensity testing, which measures the tensile strength of the concrete indirectly.

How does the split intensity testing frame work?

-The split intensity testing frame applies a horizontal compression load to the cylinder, which is then converted into an axial tensile force, causing the cylinder to split into two parts.

What is the role of timber bits in the split intensity test?

-Timber bits are placed on either side of the cylinder in the split intensity test frame to ensure proper alignment and to prevent the cylinder from moving during the test.

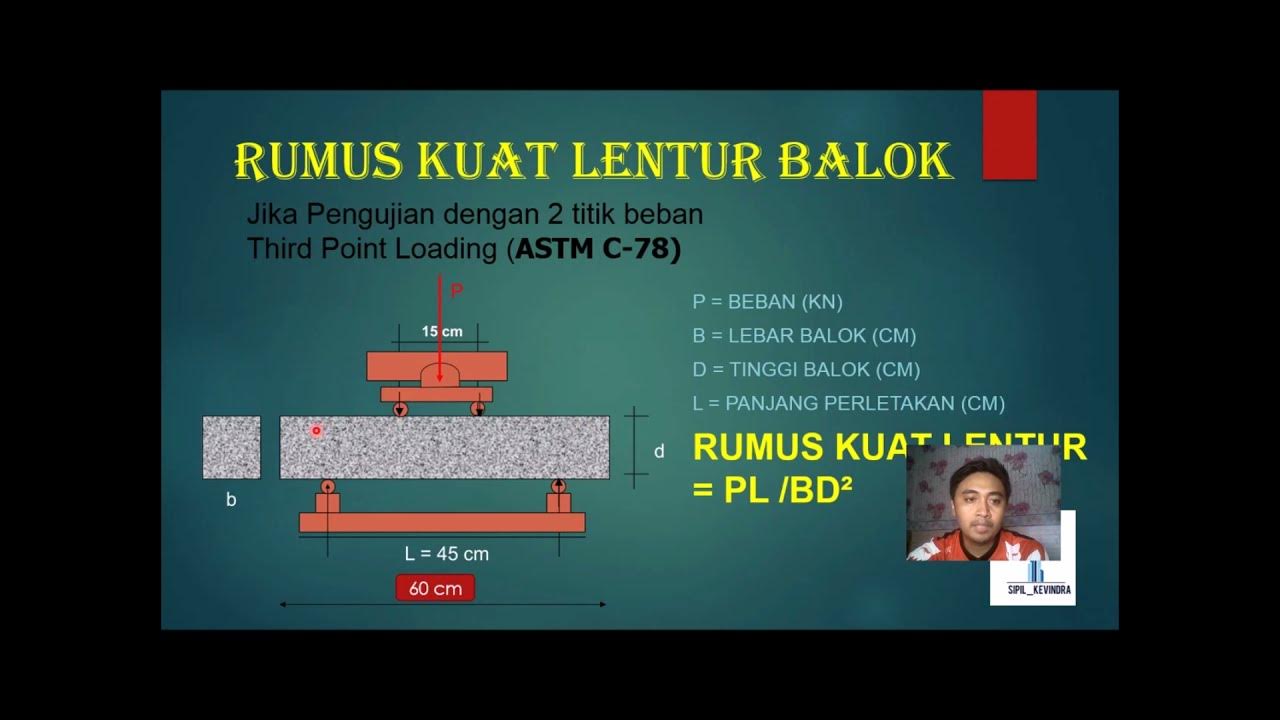

What is the four-point bending test and how is it set up?

-The four-point bending test is a flexural test that measures the bending strength of a specimen. It is set up with two points of load application and two roller supports, creating a setup with two spans.

What is the maximum force the MTS machine used in the script can apply?

-The MTS machine used in the script can apply a maximum force of 3000 Newtons, with the possibility of upgrading for higher forces if required.

How does the compressive strength test work on the MTS machine?

-In the compressive strength test on the MTS machine, a constant pressure is applied to the top surface of the cylinder by the movable arm until the cylinder is crushed.

What is the significance of presenting the type of specimen (cylinder or cube) when reporting compressive strength?

-Presenting the type of specimen (cylinder or cube) when reporting compressive strength is significant because it provides context for the results, as different specimen shapes can yield different strength values.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

PENGUJIAN TES KUAT LENTUR BETON

How to determine split tensile strength test of concrete || Laboratory Concrete Test #2

KEREN BANGET NIH !!!!! TUTORIAL PEMBUATAN BETON , PROGRAM STUDI TENIK SIPIL UNIVERSITAS KADIRI 😊🤩

Expt 2. Flexural Strength Test of Concrete Beam

TEKNIK UJI KUAT TEKAN BETON | ANAK TEKNIK

Pemeriksaan Kuat Lentur Kayu

5.0 / 5 (0 votes)