Cara penyambungan kabel fiber optik

Summary

TLDRThis tutorial demonstrates the step-by-step process of connecting fiber optic cables, focusing on proper safety precautions and precise techniques. The guide covers essential steps such as stripping the cable layers, cleaning the fiber, making accurate cuts, and using fusion splicing equipment to connect the fibers. It also emphasizes the importance of maintaining tools, checking connections with testing equipment like OPM and OLS, and ensuring the quality of the splice. The tutorial concludes by showing how to protect the joint and verify the connection’s success through light transmission.

Takeaways

- 😀 Safety First: Always wear safety gear like safety glasses and gloves before working with optical fibers.

- 😀 Proper Fiber Stripping: Use the correct tools to strip the outer and inner layers of the optical fiber.

- 😀 Clean the Fiber: Clean the stripped fiber thoroughly with alcohol and tissue to ensure no dirt remains.

- 😀 Precision in Cutting: Ensure the fiber is cut properly (around 15mm) for optimal splicing.

- 😀 Fusion Splicing: Use a fusion splicer to connect the fibers, ensuring the ends align properly without exceeding the marker on the holder.

- 😀 Re-checking Cuts: If the splice fails, re-check the fiber cuts, as misalignment or rough cuts can lead to connection issues.

- 😀 Tool Maintenance: Regularly maintain the cutting tools to ensure clean cuts; dull blades can affect splice quality.

- 😀 Fiber Protection: After splicing, use a heat shrink tube to protect the fiber from environmental damage such as moisture or heat.

- 😀 Splice Testing: Always test the splice using Optical Power Meter (OPM) and Optical Loss Tester (OLS) to verify the connection's quality.

- 😀 Proper Fiber Handling: Handle the fiber with care, ensuring no bends or pressure that could damage the cable during installation.

- 😀 Successful Splice Indicators: A successful splice is indicated by a stable reading on the OPM and minimal loss in the splice (preferably under 0.01 dB).

Q & A

What is the first step in the fiber optic cable joining process?

-The first step is to ensure safety by wearing the necessary protective equipment, such as safety glasses, before starting the procedure.

Why is it important to clean the fiber optic before cutting?

-Cleaning the fiber optic before cutting ensures that no dirt or contaminants interfere with the fusion process, which could lead to poor splice quality.

How do you strip the fiber optic cable?

-The fiber optic cable is stripped in two stages. The first layer, the outer yellow protective layer, is removed with a specific stripping tool, and the second layer is peeled using a different tool.

What should the length of the fiber be when cutting it for fusion splicing?

-The fiber should be cut to a length of approximately 15 mm, as this is the standard for ensuring a proper splice.

What happens if the fiber is cut incorrectly?

-If the fiber is cut incorrectly, the splice may fail, as a clean, straight cut is necessary for a proper fusion. In such cases, the cutting process needs to be repeated.

What is the purpose of the fusion splice machine?

-The fusion splice machine is used to precisely join two fiber optic ends together by fusing them with heat, ensuring a seamless connection between the fibers.

Why is it important to avoid over-extending the fibers in the fusion splice machine?

-Over-extending the fibers in the fusion splice machine can prevent the fibers from being properly fused, leading to a poor connection. The fibers should not extend past the middle marker on the machine.

What protection is applied to the fiber after splicing?

-After the fiber is spliced, protective coverings, such as heat shrink tubes, are applied to safeguard the splice from environmental factors like heat, moisture, and physical damage.

How is the success of the fiber optic splice tested?

-The success of the splice is tested using an Optical Power Meter (OPM) and Optical Light Source (OLS). A successful splice is indicated by light passing through the fiber without interruptions.

What does the result of -8.84 dB indicate in the testing process?

-A result of -8.84 dB indicates that the fiber optic splice has minimal signal loss and is functioning well, meaning the splice quality is acceptable and the connection is reliable.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Penyambungan Kabel Fiber Optik | Teknik Penyambungan Kabel Fiber Optik

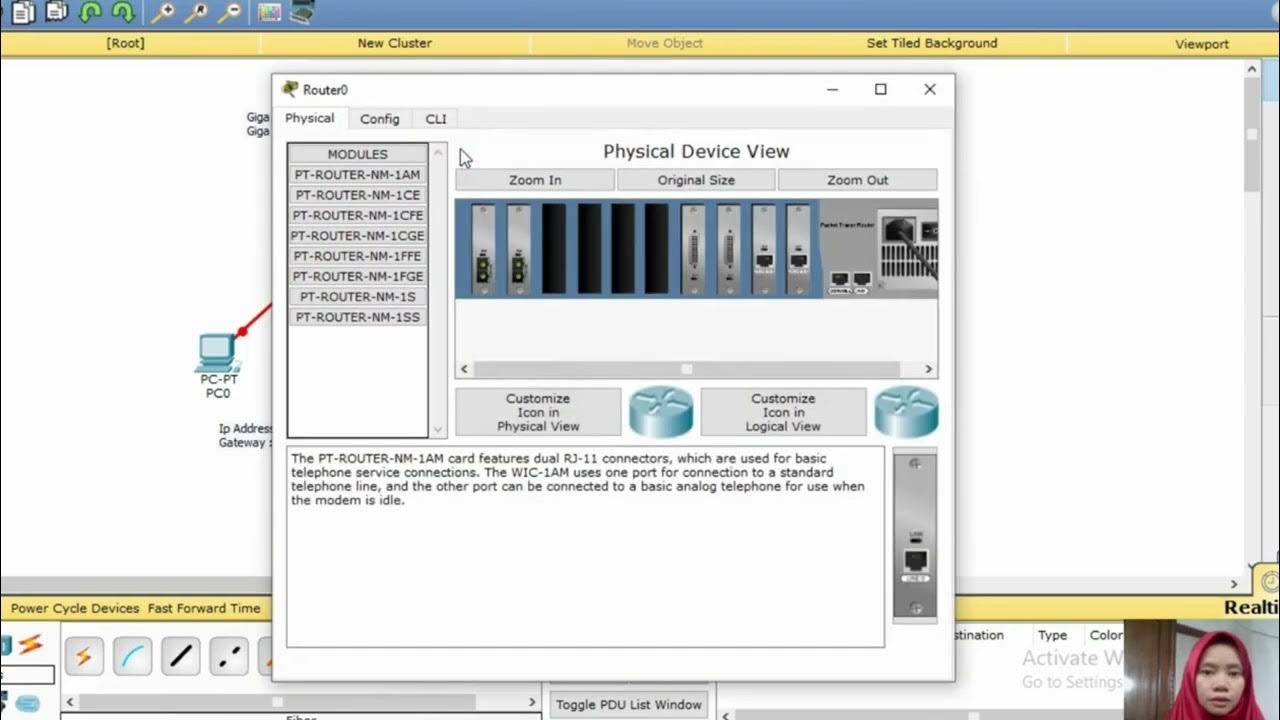

Tutorial Konfigurasi Jaringan Fiber Optik dengan Cisco Paket Tracer

Cara Menyambung Kabel Fiber Optik Menggunakan Splicer (Dropcore, Patchcord, Pigtail)

Cara Splicing Kabel Fiber Optic Untuk Pemula

Cara Pasang Fast Connector Fiber Optic Sendiri secara Manual (Tanpa Alat Splicer)

Mengoperasikan OTDR (Optical Time Domain Reflectometer) - Teknik Jaringan Akses Telekomunikasi

5.0 / 5 (0 votes)