Apa Itu Sloof? Bahan Pembuatan Sloof? Fungsi Sloof? Ukuran Sloof?

Summary

TLDRIn this video, the presenter explains the process of constructing a 'sloof' or structural beam in home construction. The video covers essential topics such as the purpose and components of a sloof, the materials used (concrete and reinforcement bars), and the different types of reinforcement required based on the size of the building. It also provides guidelines for measurements, including typical reinforcement diameters for single, two, and three-story buildings. The importance of earthquake-resistant construction is emphasized, highlighting the role of precise leveling and alignment in the process. Viewers are encouraged to engage with the content, ask questions, and subscribe for future updates.

Takeaways

- 😀 Sloof (or SLOOF) is a structural element in building construction that sits between the foundation and the columns, made of reinforced concrete (concrete and rebar).

- 😀 The main function of sloof is to distribute the load evenly to the foundation, ensuring the building remains stable even in the case of ground shifts or movement.

- 😀 The components of sloof include corner reinforcement (tulang pojok), waist reinforcement (tulang pinggang), and stirrups (tulangan Sengkang or cincin).

- 😀 For single-story buildings, common reinforcement sizes are: corner reinforcement D13, waist reinforcement D10, and stirrups D8.

- 😀 For two-story buildings, reinforcement sizes increase to: corner reinforcement D13 or D16, waist reinforcement D12/13, and stirrups D10.

- 😀 For buildings with three stories or more, the reinforcement sizes are: corner reinforcement D16, waist reinforcement D13, and stirrups D8.

- 😀 The materials used for reinforcement include threaded rebar for the corner and waist reinforcement, and smooth rebar for the stirrups.

- 😀 The concrete mix ratio for sloof typically follows a 1:7:9 ratio, which means 1 sack of cement, 7 buckets of sand, and 9 buckets of gravel.

- 😀 Constructing sloof from excavation, reinforcement, to pouring concrete generally takes 1-2 months for a single-story house.

- 😀 Given Indonesia’s seismic zone, buildings should adhere to earthquake-resistant construction practices, and sloof should be leveled and aligned with walls and columns to ensure optimal function.

Q & A

What is a 'sloof' in construction?

-A 'sloof' refers to a structural element in a building, which is located between the foundation and columns. It functions to evenly distribute loads above it to the foundation.

What materials are used to make a 'sloof'?

-A 'sloof' is typically made of concrete and reinforcement steel, also known as reinforced concrete.

What is the primary function of a 'sloof'?

-The primary function of a 'sloof' is to transfer loads above it evenly to the foundation, ensuring the building remains stable, even if the ground shifts.

What are the different components of a 'sloof'?

-The components of a 'sloof' include corner reinforcement (tulang pojok), mid-reinforcement (tulang pinggang), and stirrups or rings (tulangan Sengkang).

What are the typical reinforcement sizes used for different building types?

-For a one-story building, corner reinforcement is typically D13, mid-reinforcement D10, and stirrups D8. For two-story buildings, corner reinforcement is D13 or D16, mid-reinforcement D12/13, and stirrups D10. For buildings with three or more floors, corner reinforcement is D16, mid-reinforcement D13, and stirrups are D8 or stronger.

How is the concrete mix for a 'sloof' typically proportioned?

-The standard concrete mix for a 'sloof' is in the ratio of 1:7:9, which is one part cement, seven parts sand, and nine parts gravel.

How long does it take to construct a 'sloof' from excavation to pouring?

-The process of creating a 'sloof' from excavation to concrete pouring usually takes about 1 to 2 months for a single-story building.

Why is it important to consider seismic safety when building in Indonesia?

-Indonesia is prone to earthquakes, so it is crucial to incorporate earthquake-resistant construction techniques in the design and construction of buildings, including the 'sloof' phase.

What should be considered during the 'sloof' construction to ensure safety?

-During the construction of a 'sloof,' it is essential to pay attention to the leveling of the building, as well as the proper positioning of walls and columns to ensure the structure functions correctly.

What should viewers do if they have more questions about 'sloof' construction?

-Viewers are encouraged to leave their questions in the comments section of the video, and they can also support the channel by subscribing and turning on notifications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

The Secret Behind the "I-Beam" Strength

Steel Connections Every Structural Engineer Should Know

[Struktur Baja 2]: Perhitungan Sambungan Balok-Kolom Baja

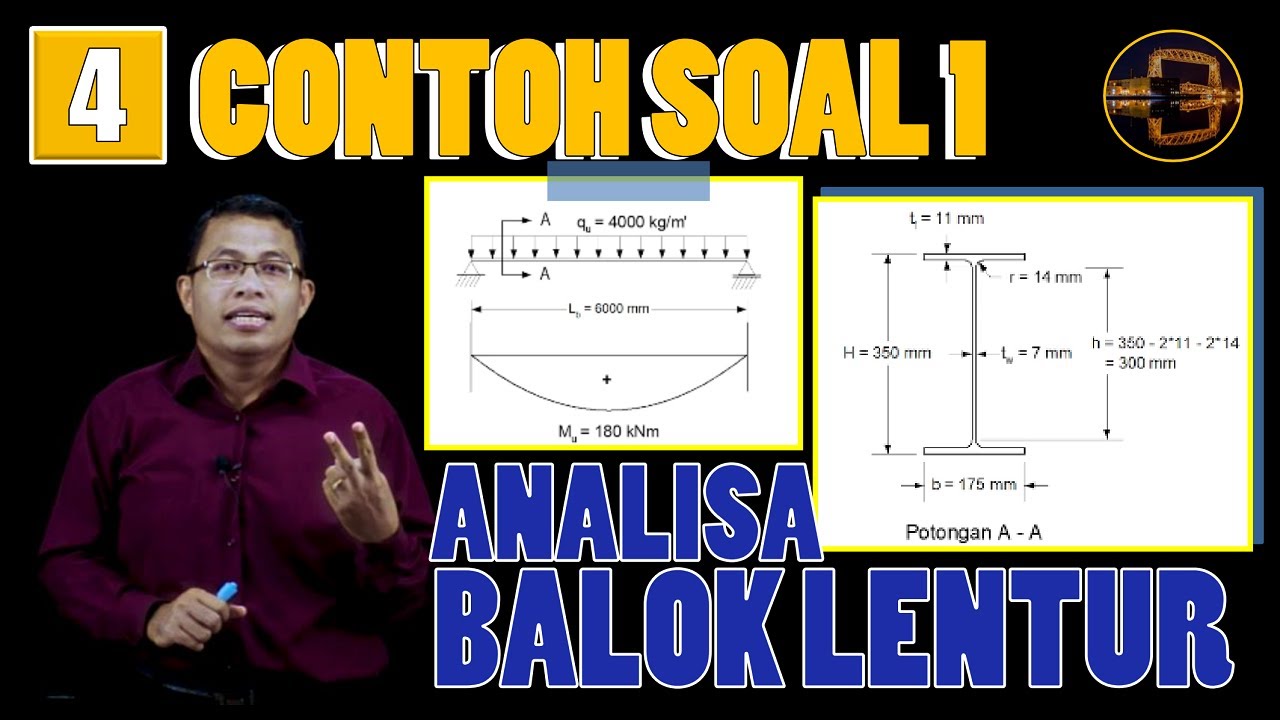

Contoh Perhitungan Analisa Balok Anak dgn Plastik Sempurna (Leleh Umum) | Struktur Baja | Lightboard

CARA MENCARI UKURAN BALOK BETON || ukuran balok rumah 2 lantai

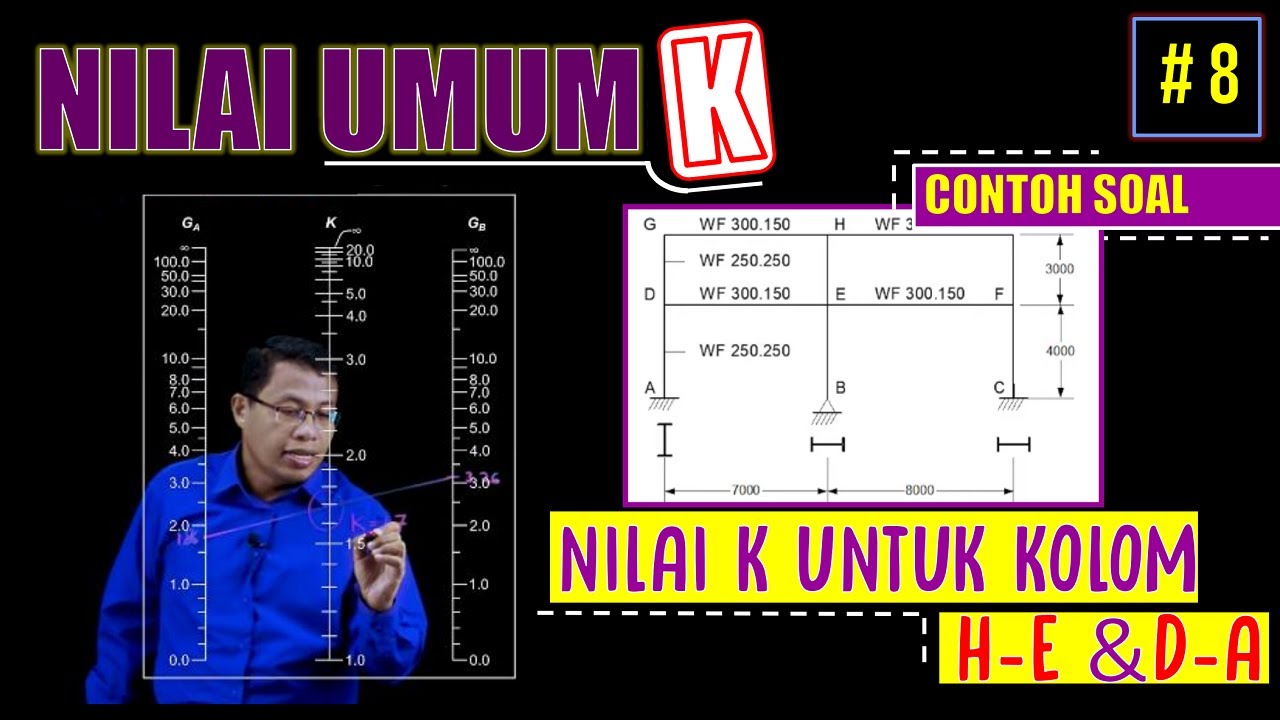

Contoh Perhitungan Nilai Umum K Batang Tekan Struktur Baja | Lightboard

5.0 / 5 (0 votes)