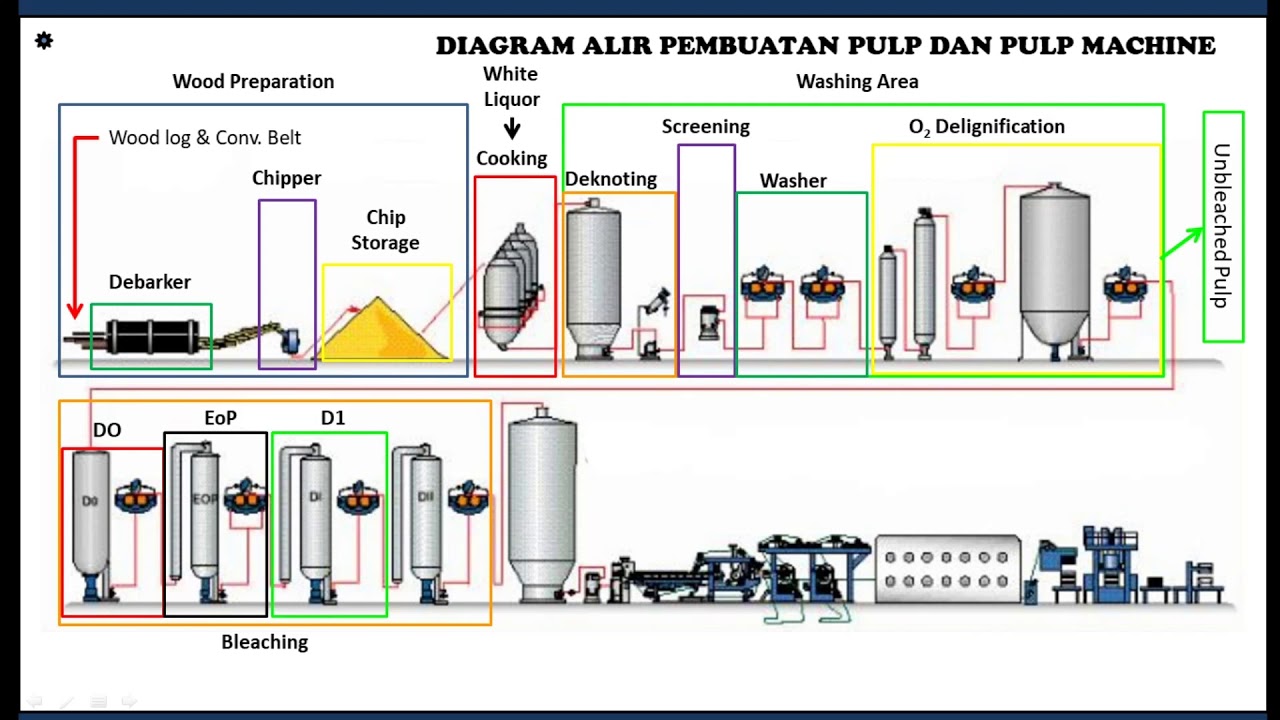

Pulp Making Process (Cooking, Washing, and Bleaching)

Summary

TLDRThis video explains the process of making paper, focusing on the stages of bleaching and purification. It covers the D1 and D2 stages, with D2 involving chlorine dioxide to improve the brightness and purity of the pulp. The process aims to achieve a brightness of 89.5%-90%, while maintaining specific parameters like pH, temperature, and consistency. The D2 stage eliminates color impurities such as residual lignin, ensuring the final product is white and high-quality. The video offers a comprehensive guide to these critical steps in the paper-making process.

Takeaways

- 😀 The bleaching process is crucial in paper production, specifically to achieve the desired brightness and purity of the final product.

- 😀 The D1 stage aims to remove lignin, which affects the color of the paper, using a controlled process involving chlorine dioxide.

- 😀 Brightness levels after the D1 stage should exceed 89.5%, targeting a range of 89.5% to 90%.

- 😀 The pH value during the D1 stage must be maintained between 3.5 and 5 to ensure the effectiveness of the bleaching process.

- 😀 Temperature control is critical in both D1 and D2 stages, with temperatures ranging from 60-85°C.

- 😀 The consistency of the pulp during the bleaching process should be between 10% to 15%, ensuring optimal reaction conditions.

- 😀 Retention time during the bleaching process should be maintained between 2-5 hours for effective treatment.

- 😀 The D2 stage continues the bleaching process, further purifying the pulp and removing any remaining colored compounds.

- 😀 The goal of the D2 stage is to ensure that the pulp is free from any unwanted substances that may affect the final paper quality.

- 😀 The video provides a comprehensive overview of the pulp bleaching process, from initial bleaching to final purification, highlighting the importance of each step.

Q & A

What is the purpose of the D2 stage in the bleaching process?

-The D2 stage is focused on purifying the material by removing compounds that contribute to unwanted color, particularly lignin, using chlorine dioxide.

What temperature range is specified for the D2 stage of the process?

-The temperature range for the D2 stage is between 60°C and 85°C.

What is the target brightness level for the material after the D2 stage?

-The target brightness level is between 89.5% and 90% after the D2 stage.

What is the consistency range for the material in the D2 stage?

-The consistency range for the material in the D2 stage is between 10% and 15%.

What is the significance of the retention time in the D2 stage?

-The retention time of 2-5 minutes is important for allowing the chlorine dioxide to effectively purify and remove color-causing compounds from the material.

What chemical is used during the D2 stage for purification?

-Chlorine dioxide is used in the D2 stage for the purification process to eliminate color-causing compounds.

Why is it important to achieve a brightness level of 89.5-90%?

-Achieving a brightness level of 89.5-90% is critical to ensure that the material meets the required standards for appearance and quality.

What happens if the D2 stage does not remove color-causing compounds effectively?

-If the D2 stage does not remove color-causing compounds effectively, the final product may have undesirable color, which can affect its quality and appearance.

What role does chlorine dioxide play in the bleaching process?

-Chlorine dioxide acts as a bleaching agent, breaking down lignin and other compounds that contribute to the color in the material, improving its brightness.

How does the process of bleaching contribute to the overall quality of the product?

-The bleaching process, specifically the D1 and D2 stages, helps remove impurities, improve brightness, and ensure the final product is of high quality with a desirable appearance and minimal color contamination.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)