CARA BUKA KERAN HYDRANT, CARA MEMASANG NOZZLE DAN SELANG DI SIAMESE CONNECTION FIRE HYDRANT TRAINING

Summary

TLDRThe video transcript discusses technical procedures for managing water and gas systems, including the installation and maintenance of piping with varying pressure levels. It emphasizes the importance of handling high-pressure systems carefully to avoid leaks and accidents. The speaker covers topics such as adjusting water flow, controlling pressure, and safely operating equipment. There are mentions of practical steps and cautionary advice for workers, alongside humor about potential mishaps. Overall, the content aims to inform about proper handling of pressure systems, while also addressing safety protocols and the importance of teamwork in industrial settings.

Takeaways

- 😀 The importance of water pressure management is emphasized, especially in scenarios where high-pressure systems are used, like with machinery or pipelines.

- 😀 Pressure loss occurs during transmission, and it is noted that if the pressure drops significantly (e.g., from 55 bar to 5 bar), it could cause issues like leaks or loss of function.

- 😀 A change in pipe sizes (e.g., from 2.5-inch to 1.5-inch) helps adjust the pressure for easier use, particularly in environments that require lighter pressure.

- 😀 The proper handling of high-pressure systems is crucial. Incorrect handling can lead to equipment failure, such as broken seals or pipes.

- 😀 Safety protocols are emphasized, particularly in preventing accidents due to sudden pressure release or mismanagement of equipment.

- 😀 The importance of training on pressure control is highlighted. Only personnel who are trained should handle high-pressure systems.

- 😀 There is a focus on the safety of helpers or workers who assist in high-pressure tasks, with specific instructions on how to position themselves to avoid accidents.

- 😀 Proper procedure when operating hydraulic systems includes careful handling and checking of equipment to ensure everything is working correctly, such as pressure gauges and nozzles.

- 😀 When working with equipment under pressure, workers must ensure that all valves and fittings are secure and properly maintained to avoid catastrophic failure.

- 😀 The script alludes to the practical challenges workers face when dealing with high-pressure machinery, such as the need to control flow and pressure efficiently while preventing leaks or equipment damage.

Q & A

What is the main focus of the discussion in the transcript?

-The main focus of the transcript revolves around the operation and management of water pressure systems, particularly in relation to different pipe sizes, water pressure handling, and safety measures during maintenance or installation.

What happens if there is a reduction in water pressure during the operation?

-A reduction in water pressure leads to a decrease in effectiveness. For example, a pressure reduction of up to 5 bar can be significant enough to lift people, and it also impacts the overall system's functionality.

What is the importance of using the correct pipe size (e.g., 1.5 cm vs 2.5 cm)?

-Using the appropriate pipe size is essential for ensuring optimal water flow. A smaller pipe size (1.5 cm) is used for lighter usage, while a larger size (2.5 cm) is necessary for handling higher pressures or more demanding applications.

What safety precautions are emphasized when handling high-pressure systems?

-The transcript stresses that workers should avoid certain positions and actions when working with high-pressure systems, particularly ensuring they do not push or handle equipment improperly, which could result in accidents or failures.

What does the term 'helper' refer to in the context of this discussion?

-In the context of this discussion, the 'helper' is a person who assists in managing the equipment, particularly in controlling or guiding the high-pressure water systems to prevent accidents or mishandling.

Why is it important to manage pressure carefully when working with water systems?

-Managing pressure carefully is crucial because improper handling can lead to dangerous outcomes, such as equipment failure, pressure loss, or even injury. Proper pressure control ensures that the system operates safely and effectively.

What is the role of 'hydrant' in the water system, according to the transcript?

-The hydrant is used as a control point to manage the flow and pressure of water. The discussion mentions the process of opening and using a hydrant, ensuring the proper handling of water and preventing accidents.

What potential hazards are highlighted in the transcript?

-The potential hazards include water pressure loss, accidental leakage, and unsafe handling of high-pressure systems. It is also suggested that workers should be cautious of certain materials, like bottles, potentially hidden inside the system.

How does the use of 'spre' relate to water system operations?

-The term 'spre' refers to a type of protective covering or sheet that is used during the operation. It is mentioned in relation to preventing accidents or reducing the risk of damage when handling water pressure systems.

What was the purpose of mentioning the old practices, such as inserting bottles in the system?

-The mention of old practices, such as inserting bottles, serves as a reminder of past unsafe behaviors and possibly as a cautionary tale to highlight the importance of safety and proper procedures in modern operations.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Piping Fundamentals. Piping Study. Piping Basic

FRAMO PANNEL IN CARGO CONTROL ROOM(Power pack on tanker ship)

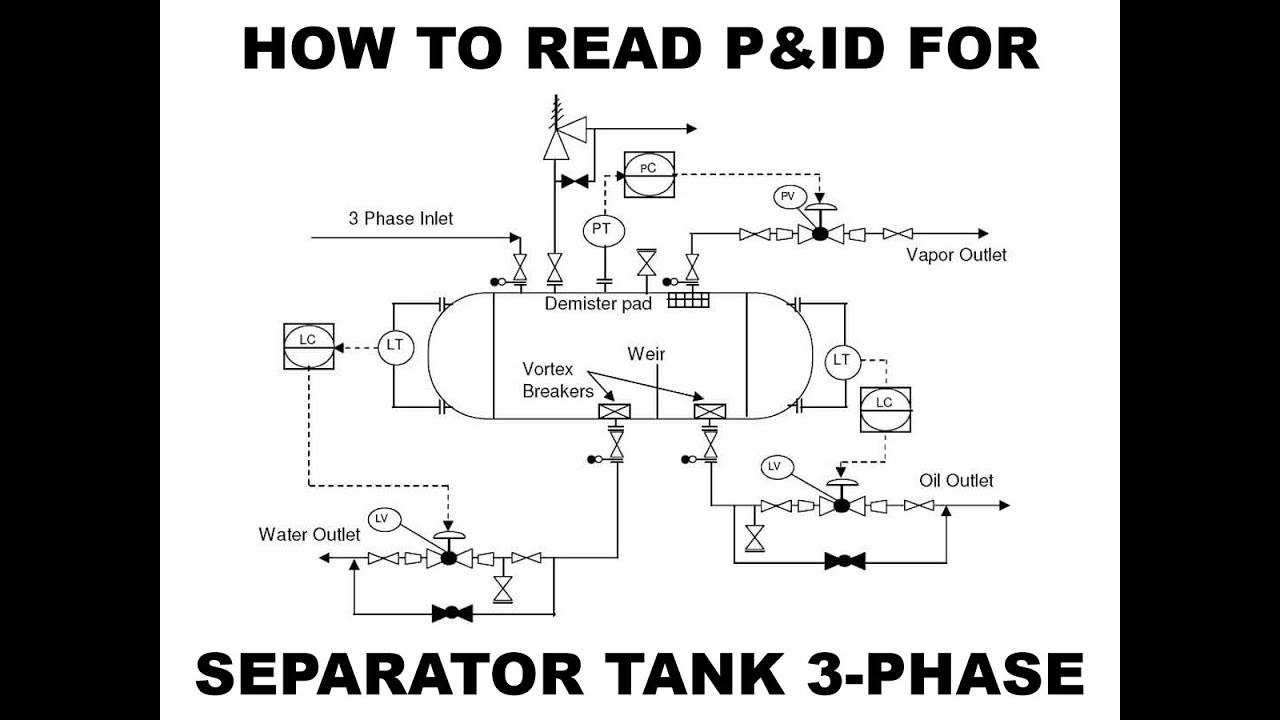

How To Read P&ID Diagram for Separator Tank (3-Phase) in Malay - Nazmi Ismail

Inert Gas System Maintenance

हिंदी Oggy and the Cockroaches - Oggy Goes Green (S04E32) - Hindi Cartoons for Kids

What is Water Hammer? | DFT Inc.

5.0 / 5 (0 votes)