Inert Gas System Maintenance

Summary

TLDRThe video provides a detailed overview of the maintenance requirements for an inert gas system, highlighting its three main components: the scrubber, inert gas fan, and deck water seal. It emphasizes the importance of regular checks and maintenance procedures to ensure optimal performance and safety. Key tasks include running cooling water through the scrubber, inspecting and washing the fan, and maintaining water levels in the deck seal. Adhering to the instruction manual is crucial for preventing issues like corrosion and gas leaks, ultimately ensuring the system functions effectively throughout its operation.

Takeaways

- 🛠️ Regular maintenance of the inert gas system is essential for safe and efficient operation.

- 💧 After using the scrubber, let the cooling water flow for 30 minutes by running the scrubber pump continuously.

- 🔍 Conduct yearly maintenance on the scrubber, including checks for spray nozzle wear, lining integrity, and corrosion.

- 🔒 Ensure the manhole cover of the scrubber tower is properly closed after maintenance to prevent leaks.

- 🌀 Clean the inert gas fan regularly to avoid corrosion and unbalance from solid particle deposits.

- 🚫 Washing of the fan must only be done when it is completely stopped to prevent damage to the impeller and casing.

- ⏲️ When washing the fan, turn the impeller slowly for 10 to 15 minutes to ensure thorough cleaning.

- 💧 The deck water seal isolates flammable vapor from the cargo tank to the boiler, requiring continuous water supply.

- 📏 Regularly check the water level in the deck water seal to maintain adequate sealing.

- 🔧 Periodically inspect and clean the internal components of the deck water seal, including the demister pad.

Q & A

What are the main components of the inert gas system?

-The main components of the inert gas system include the scrubber, inert gas fan, and deck water seal.

Why is periodic maintenance important for the inert gas system?

-Periodic maintenance ensures that the inert gas system remains in good working condition, preventing failures and maintaining safety.

What is the procedure for maintaining the scrubber after usage?

-After usage, the scrubber pump should run continuously for about 30 minutes to let cooling water flow through.

What should be checked during the yearly maintenance of the scrubber?

-During yearly maintenance, check the spray nozzles for wear and clogging, inspect the lining for corrosion, and ensure the manhole cover is properly closed after maintenance.

How can solid particles affect the inert gas fan?

-Solid particles can deposit on the impeller and casing, potentially causing corrosion and unbalance of the impeller blades.

What is the recommended method for washing the inert gas fan?

-To wash the fan, ensure it is completely stopped, connect the washing hose, open the valve, and wash the impeller slowly for 10 to 15 minutes.

What maintenance steps should be taken for the deck water seal?

-Check the seal water level continuously, inspect the internal coating periodically, clean the demister pad, and check for corrosion of components.

Why is it crucial to maintain the water level in the deck water seal?

-Maintaining the water level in the deck water seal is crucial to effectively isolate flammable vapor from the cargo tank to the boiler.

What could happen if washing the inert gas fan while it is operational?

-Washing the fan while it is operational can cause serious damage to the impeller and casing.

What is the role of the scrubber in the inert gas system?

-The scrubber removes impurities from the inert gas, utilizing a Venturi, packed tower, and misting elements to ensure the gas is clean before use.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

The Alfa Laval system for producing high-quality inert gas for cargo ships

Why We Need To Purge The Cargo Tanks Before Making Them Gas Free

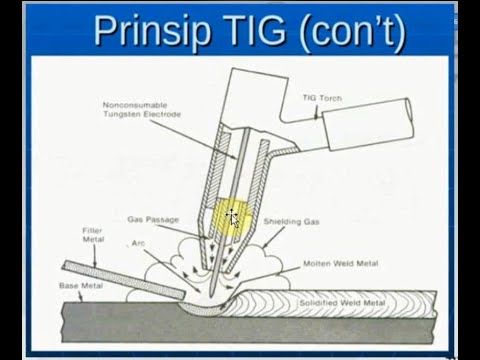

Prinsip Kerja dan Komponen Las TIG (Tungsten Inert Gas)

How LNG Carriers (Gas Tankers) Work - Design Types, Loading & Discharge

Induction Motor Construction (Squirrel Cage Rotor)

STATIC EQUIPMENT / OIL& GAS professional

5.0 / 5 (0 votes)