PASCA PANEN BAWANG MERAH

Summary

TLDRThis video provides a detailed guide on the post-harvest handling of shallots, covering essential steps like harvesting, curing, drying, cleaning, sorting, grading, and packaging. The script emphasizes the importance of proper post-harvest practices to ensure high-quality shallots that have a longer shelf life, reduced spoilage, and are market-ready. Key techniques include drying the shallots to reduce moisture, sorting by size and quality, and using proper storage and transportation methods. The process helps improve product competitiveness, minimize losses, and boost financial returns for producers.

Takeaways

- 😀 Harvesting red onions should occur when 60-70% of the leaves have turned yellow, and the bulbs are slightly above the soil surface.

- 😀 Onions are harvested manually by uprooting the plants and tying the leaves into bundles of about 1 kg each for easier handling.

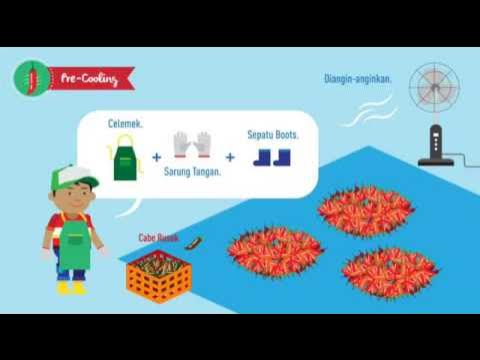

- 😀 The initial curing process is essential for healing the wounds of harvested onions and reducing moisture content. This is done by placing onions under shade for 2-3 days.

- 😀 Onions should be arranged with leaves facing upwards during curing to speed up the drying process and ensure thorough drying.

- 😀 The drying process continues until the outer skins of the onions easily peel off, which takes about 7-8 days for consumption onions and up to 15 days for seed onions.

- 😀 After drying, onions are cleaned by removing dried leaves, roots, dirt, and any damaged or rotting bulbs to maintain quality.

- 😀 Sorting and grading are done based on size, cleanliness, and the absence of diseases or damage. Onions are categorized into three grades based on their diameter.

- 😀 Proper storage is key to extending the shelf life of onions, requiring clean, dry, and well-ventilated storage areas that prevent mold and spoilage.

- 😀 Onions should be packed using different packaging methods based on the market type (e.g., mesh bags for local markets, perforated plastic for supermarkets).

- 😀 Proper distribution requires careful handling during transport to prevent damage, with attention to road conditions and the duration of travel to maintain quality.

- 😀 Proper post-harvest handling can reduce onion loss from 25-40% to a much lower percentage, resulting in better quality, longer shelf life, and higher market competitiveness.

Q & A

What is the main purpose of post-harvest handling for red onions?

-The main purpose of post-harvest handling is to improve the quality of red onions, extend their shelf life, reduce crop loss, and enhance competitiveness in the market by following proper procedures in harvesting, drying, cleaning, sorting, storage, and distribution.

How can you determine when red onions are ready for harvest?

-Red onions are ready for harvest when the leaves start to wither and turn yellow (60–70% of leaves), the bulbs begin to protrude from the soil, and the onions develop a characteristic smell. Additionally, the bulbs should be full and the color of the onion should change to purple.

What are the ideal harvesting times for red onions in different altitudes?

-In lowland areas, red onions should be harvested 50–60 days after planting, in medium altitudes 70–75 days, and in high-altitude regions 80–100 days after planting.

What is the role of curing in post-harvest handling of red onions?

-Curing helps to close wounds that occur during harvesting and allows the onion to heal. It also aids in reducing moisture content, preparing the onion for further drying, and extending its shelf life. Curing is done by keeping the onions in a shaded area and turning them regularly for even drying.

How should onions be arranged during the curing process?

-During curing, onions should be placed on a tarpaulin with the tops facing upward to allow the leaves to dry quickly. They should be spaced out to avoid piling, which could lead to uneven drying. The onions should also be turned periodically to ensure uniform exposure to sunlight.

How long does the extended drying process typically take for red onions?

-The extended drying process typically takes 7–8 days for onions meant for consumption. For seed onions, the drying period is longer, usually taking 12–15 days to ensure they achieve the desired color and texture.

Why is sorting and grading important after drying red onions?

-Sorting and grading are essential for ensuring that only high-quality onions are sold. This process involves separating onions based on size, cleanliness, firmness, and the absence of disease or damage. It helps maintain product quality and meets market requirements.

What are the different quality grades for red onions?

-Red onions are classified into three quality grades based on size: Grade 1 (large bulbs with a diameter of 3–4 cm), Grade 2 (medium bulbs with a diameter of 2–3 cm), and Grade 3 (small bulbs with a diameter of less than 2 cm).

What conditions should be maintained during the storage of red onions?

-During storage, red onions should be kept in a clean, dry environment with good air circulation to prevent moisture buildup. The storage area should be ventilated and free from humidity, which could cause rot. Onions should be stored on racks or shelves designed for proper airflow.

How should red onions be packaged for different markets?

-For local markets, onions are typically packed in perforated plastic bags, baskets, or net bags, with a capacity of 25–30 kg. For supermarkets, onions are packaged in trays or wrapped in transparent plastic with ventilation holes, usually in 0.25–0.5 kg portions. For export, onions are packed in specially designed cardboard boxes (15–20 kg capacity) with ventilation holes.

What factors should be considered during the transportation of red onions?

-During transportation, factors such as the condition of the roads, travel time, and temperature should be considered. Proper care should be taken to prevent damage, including proper stacking to avoid crushing and ensuring the onions are kept in optimal conditions to preserve their quality during transit.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)