BUILD: Scissor Lift!

Summary

TLDRIn this video, the creator details the process of designing and building a custom motorcycle lift using a scissor mechanism. They share insights into design challenges, such as managing the screw's compression versus tension, optimizing height for ease of use, and considering future improvements like adding castor wheels for mobility. The creator reflects on design choices, explaining how some decisions, such as the placement of the drive mechanism, could have been better executed. Despite the setbacks, they are pleased with the final product and encourage others to try building similar projects, though they humorously state they’re unlikely to build another scissor mechanism again.

Takeaways

- 😀 The creator initially set out to build a scissor lift for their bike, but faced challenges when it came to working with stainless steel, a material they dislike.

- 😀 The design of the scissor lift involved using a variety of parts, including custom-made links, spacers, bushings, and bearings to ensure proper movement and functionality.

- 😀 The creator used 3D printing to expedite the creation of multiple scissor links but had to go back and modify them due to a design flaw in the rounding of the ends.

- 😀 The construction process was a mix of using traditional methods and adapting with shortcuts, such as using snap rings or welding instead of using more complex machining techniques.

- 😀 Disc springs (Belleville washers) were used in the design to ensure that the scissor mechanism would not bind during operation by compensating for small variations in parts.

- 😀 The scissor lift mechanism was designed to be manually actuated with a screw, turning the screw would spread or pull together the links to raise and lower the lift.

- 😀 One mistake in the design involved placing the drive mechanism in a way that put the screw under compression instead of tension, but the creator felt this wouldn't be a major issue for the weight of the bike.

- 😀 The creator encountered issues with the size and mobility of the lift, such as having to slide it under the bike while it was on the kickstand, but noted that making it just a few inches taller could have solved these problems.

- 😀 The creator also considered adding casters to the lift for better mobility in the garage, but was concerned that this might make the lift too unstable.

- 😀 Despite the challenges and design flaws, the scissor lift was a success, providing an easy and convenient way to raise and work on the bike, though the creator was unlikely to build another scissor mechanism in the future.

Q & A

What was the initial plan for the screw in the scissor mechanism, and why was it changed?

-The initial plan was to keep the screw in tension to prevent it from experiencing compression under load. However, due to space constraints around the rear tire, the design was flipped, placing the screw in compression instead of tension, although the speaker believes it won't matter for the size and weight of the bike.

What was one of the design flaws related to the height of the scissor mechanism?

-The speaker initially designed the scissor mechanism to slip under the bike while it was on its kickstand, but this turned out to be unnecessary. A taller design would have made it easier to lift the bike and use the driver without needing to fuss with the kickstand.

What is the speaker's intention for improving the scissor mechanism in the future?

-The speaker is considering adding small casters to the mechanism to increase its height and make it more mobile, allowing it to be wheeled around the garage. However, they also express concern that adding casters might make the mechanism too wobbly.

Why did the speaker decide to use 3D printing during the build process?

-The speaker used 3D printing as a quicker and more accessible solution to fabricate certain parts of the scissor mechanism, especially for components that could be printed in plastic, saving time and effort compared to traditional machining.

What alternative mechanical solutions did the speaker consider during the design phase?

-The speaker briefly considered using a jack shaft and bevel gear to actuate the mechanism from the side of the bike, but this solution would have been complicated due to the limited space. They also thought about using a worm gear to shift the drive mechanism below the screw, though this would be overkill.

How did the speaker address the issue of having limited space around the rear tire?

-The speaker flipped the entire assembly, positioning the drive where more space was available. However, this resulted in the screw being under compression instead of tension, which was not part of the original design.

What was the speaker's experience with the assembly process of the scissor mechanism?

-The assembly process involved challenges like welding and machining parts that required precision. The speaker adapted by using 3D printing for some components and had to troubleshoot issues related to the design's complexity and fitting the pieces together.

What does the speaker think about the future use of the scissor lift they built?

-While the speaker is satisfied with the functional outcome of the scissor lift, they express doubt about building another one, humorously stating they would never build another scissor mechanism again in their life.

What was the final conclusion of the speaker regarding the design of the scissor lift?

-The speaker concludes that, despite the minor flaws in the design, the scissor lift works as intended. They acknowledge that the project had some design mistakes but remain optimistic about its utility and consider it a learning experience.

What does the speaker suggest as a possible use for the scissor mechanism beyond its intended purpose?

-The speaker jokingly suggests using the scissor lift for a variety of uses, even recommending that it could be used to 'pick up girls,' highlighting the versatility of the design while also acknowledging that it might not be practical for everyone.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How To Make Discord MULTI-TOOL in C#!

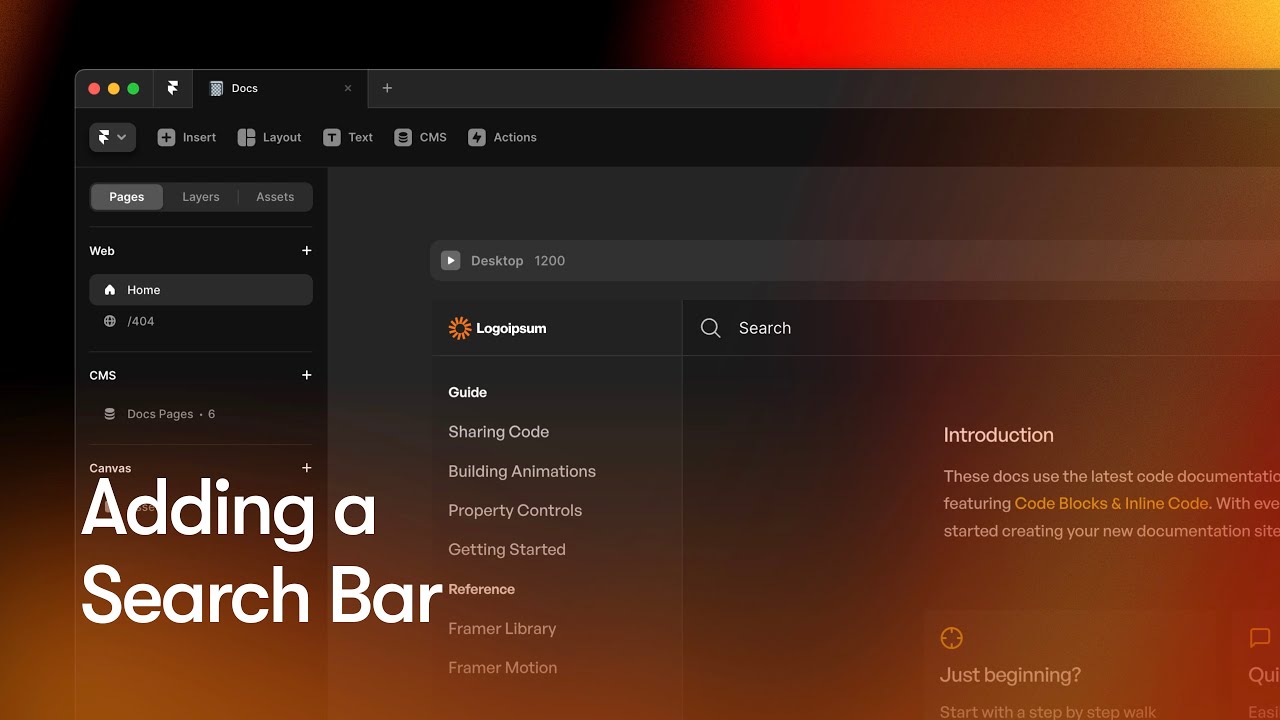

#4 Adding a Search Bar — Documentation Website in Framer

Making AI Actually Useful (Maybe)

Make your own water bottle rocket launcher! - Part 2 of 3

How to Make a Simple and Very Easy Tic Tac Toe Game in Mit App Inventor

Let’s talk about the “Impossible” Pop-up cube (Explanation and examples)

5.0 / 5 (0 votes)