Training Module 2 AIR PREPARATION (FULL)

Summary

TLDRThis module on air preparation emphasizes its critical role in ensuring the efficiency and safety of compressed air systems. It covers essential processes like filtering, regulating, and lubricating air, detailing various Norgren products designed for these tasks. Key concepts include the significance of removing contaminants like water and oil, maintaining consistent pressure, and utilizing lubricators to enhance equipment longevity. The module concludes with insights on product selection and maintenance, reinforcing the importance of proper air preparation in optimizing system performance and reducing operational costs.

Takeaways

- 😀 Proper air preparation is crucial for the efficiency and safety of compressed air systems, preventing damage and prolonging component life.

- 💧 Filtering is the first step in air preparation, essential for removing water, oil, and particulates from compressed air.

- 🔍 Different types of filters, such as general purpose, coalescing, and oil vapor removal filters, serve specific contamination needs based on application.

- 🌡️ The pressure dew point (PDP) indicates when moisture will condense, highlighting the importance of maintaining low PDP to avoid corrosion.

- 🛠️ Pressure regulation is vital for maintaining consistent pressure in the system, enhancing safety and energy efficiency.

- 💰 A small reduction in system pressure can significantly lower operational costs, demonstrating the economic benefits of proper pressure regulation.

- 🔧 Lubricators add controlled amounts of oil to pneumatic systems, enhancing the lifespan of components but require careful consideration.

- ⚙️ Relief valves and soft start valves are important for managing pressure surges and protecting equipment and personnel from hazards.

- 🗂️ Norgren's modular systems, like Exelon Plus and Olympian Plus, offer flexible and efficient solutions for air preparation needs.

- 📊 Understanding the part numbering system is essential for selecting the right products and options in air preparation.

Q & A

What is the primary importance of air preparation in compressed air systems?

-Air preparation is crucial to prevent damage to components, maximize their lifespan, and ensure safe operation within compressed air systems.

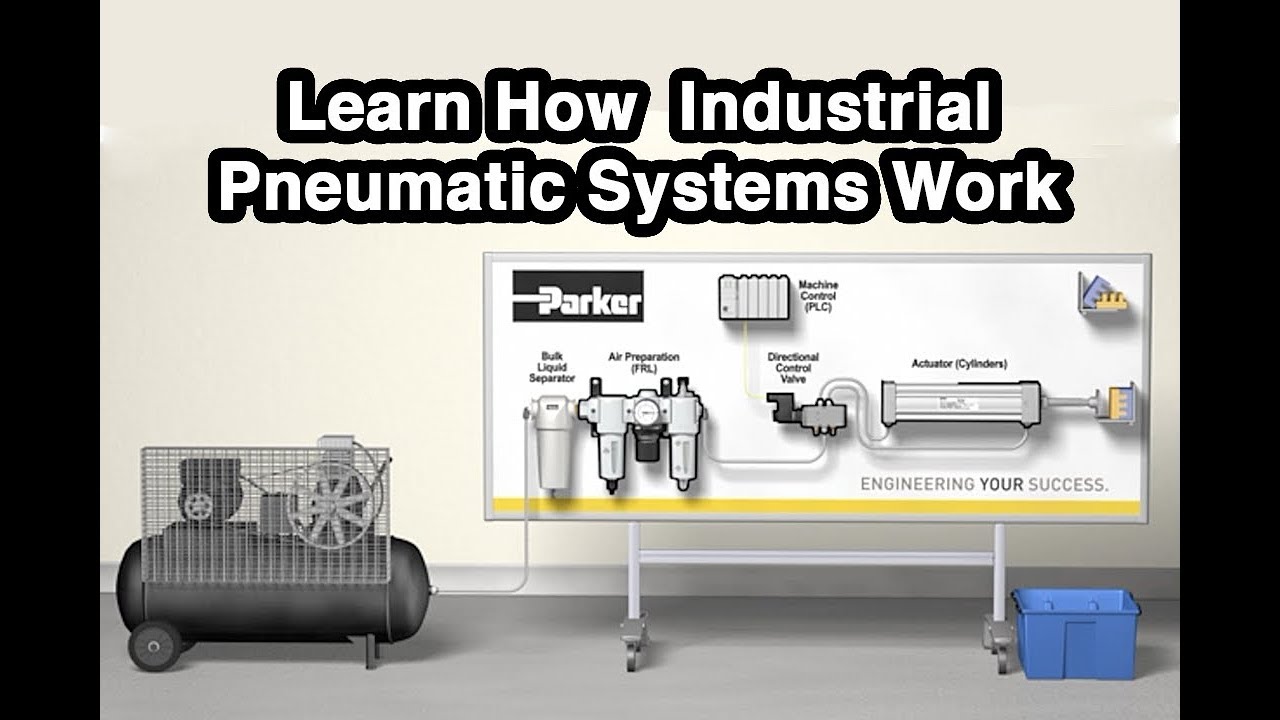

What does the acronym FRL stand for in the context of air preparation?

-FRL stands for Filtering, Regulating, and Lubricating, which are the three essential processes in air preparation.

Why is filtering considered the most important stage in air preparation?

-Filtering is vital because it removes contaminants such as water, oil, and dust that can cause corrosion and damage to the system, thus enhancing overall efficiency.

How does a dryer affect the pressure dew point (PDP) in compressed air systems?

-A dryer reduces the PDP, lowering the temperature at which condensation occurs, thus minimizing moisture in the air and preventing corrosion.

What types of filters does Norgren offer for air preparation?

-Norgren offers several types of filters, including general-purpose filters, coalescing filters, and oil vapor removal filters.

What is the function of a pressure regulator in a compressed air system?

-A pressure regulator maintains a consistent pressure level in the system, improving safety, reducing energy costs, and ensuring tools operate efficiently.

What are the benefits of using a filter-regulator-lubricator (FRL) unit?

-An FRL unit combines the functions of filtering, regulating, and lubricating into one compact unit, saving space, reducing connections, and optimizing performance.

How does a micro fog lubricator differ from a traditional oil fog lubricator?

-The micro fog lubricator creates a finer mist of oil that can travel further downstream and requires less adjustment compared to traditional oil fog lubricators.

What are the potential consequences of not maintaining filters in a compressed air system?

-Neglecting filter maintenance can lead to loss of pressure, system inefficiencies, increased wear on components, and ultimately, costly repairs.

What should be considered when selecting bowl types for air filters?

-Factors to consider include the strength and visibility of the bowl, exposure to solvents, and the specific conditions of the application, such as pressure and environmental aggressiveness.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Training Module 1 COMPRESSED AIR (FULL)

Basics of Pneumatics and Pneumatic Systems: Part 1 (Animation / Sub)

Sistemas auxiliares – Sistema de alimentação - Ar

From Radar to Radio: Tools & Technologies of Air Traffic Control

How To Start The Ship's Main Engine : From Preparation to Full Away

How a Industrial Pneumatic Systems Works And The Five Most Common Elements Used

5.0 / 5 (0 votes)