Training Module 1 COMPRESSED AIR (FULL)

Summary

TLDRThis module provides an overview of compressed air, detailing its definition, applications, and advantages in industrial contexts. Compressed air is derived from the environment and stored under pressure, serving as a clean, efficient energy source. Key concepts such as pressure and flow are explained, alongside the typical components of a compressed air system, including compressors and ring mains for air distribution. Understanding these fundamentals is crucial for troubleshooting and ensuring best practices in the use of compressed air systems, forming a solid foundation for further training.

Takeaways

- 😀 Compressed air is created by drawing in ambient air and compressing it, similar to using a bicycle pump.

- 😀 It serves as a clean energy source, producing no pollutants unlike hydraulic systems.

- 😀 The cost of compressed air systems is generally lower than hydraulic and electrical alternatives.

- 😀 Pressure and flow are critical factors in compressed air systems, directly influencing energy and actuator speed.

- 😀 The air receiver acts as a storage unit for compressed air, essential for system functionality.

- 😀 Safety valves prevent overpressure by releasing excess air, ensuring system safety.

- 😀 Proper management of condensate is necessary to avoid contamination and comply with legal disposal requirements.

- 😀 A ring main is used for even distribution of compressed air, preventing pressure drops across the system.

- 😀 Maintenance isolation can be achieved using strategically placed valves in the ring main setup.

- 😀 Compressed air is widely used in various industries, from automotive to medical applications, highlighting its versatility.

Q & A

What is compressed air?

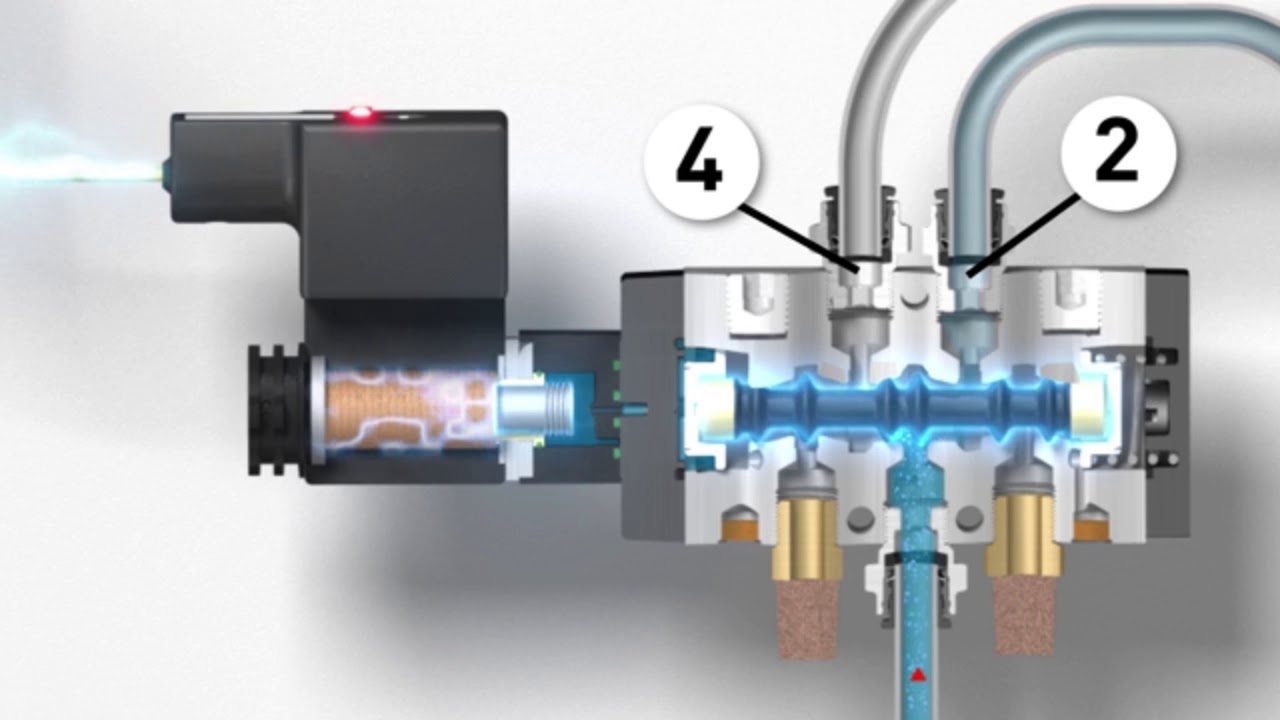

-Compressed air is created by moving ambient air into a vessel and compressing it, storing it as potential energy.

How does a bicycle pump illustrate the principle of a compressor?

-A bicycle pump works by drawing air into its chamber as the handle is pulled back and compressing it when the handle is pushed, demonstrating the basic operation of air compressors.

What are the primary advantages of using compressed air over hydraulic systems?

-Compressed air is clean, does not pollute like oil in hydraulic systems, is generally less costly, and can operate effectively under various conditions.

What units are used to measure pressure in compressed air systems?

-Pressure is typically measured in bar and psi (pounds per square inch).

What does flow refer to in the context of compressed air systems?

-Flow refers to the volume of air that can move through the system over a specific time, commonly measured in decimeter cubed per second or liters per minute.

What role does the air receiver play in a compressed air system?

-The air receiver stores compressed air, acting like a battery to maintain a supply of potential energy.

Why is it important to locate the air receiver in a cool area?

-Cool air holds less moisture, which helps prevent water from accumulating in the system, thus improving efficiency and reducing contamination.

What is a ring main and why is it used?

-A ring main is a configuration that evenly distributes compressed air throughout a facility, preventing pressure drops at distant points.

What safety measures are important when maintaining a compressed air system?

-It's crucial to exhaust air from isolated parts of the system before maintenance and to correctly dispose of any condensate to avoid contamination.

Can you name some applications of compressed air in various industries?

-Compressed air is used in automotive services, medical applications, manufacturing assembly lines, and even in amusement park rides.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)