MESIN BUBUT - DEFINISI, CARA KERJA, JENIS-JENIS DAN BAGIAN-BAGIAN MESIN BUBUT

Summary

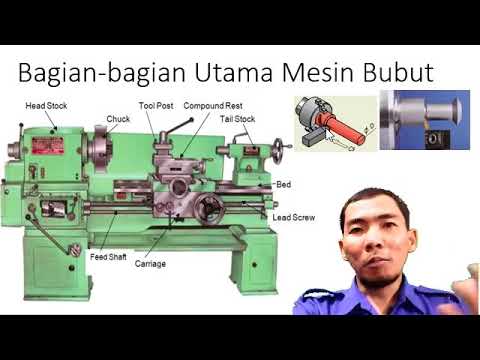

TLDRIn this informative video, viewers are introduced to lathe machines, essential tools in both industry and workshops for shaping cylindrical objects. The presenter discusses the machine's history, key components such as the headstock, carriage, tailstock, and bed, and various operations performed on the lathe, including turning, drilling, and threading. Different types of lathes are explored, from compact bench lathes to heavy-duty models used in shipbuilding. Additionally, the video covers workholding methods, highlighting the importance of precision in machining. This engaging overview encourages viewers to delve deeper into the fascinating world of lathe machinery.

Takeaways

- 🔧 Lathe machines are essential tools used in various industries for shaping cylindrical objects.

- 📜 The history of turning dates back to ancient civilizations, showcasing its long-standing importance in manufacturing.

- 🛠️ The main components of a lathe machine include the headstock, carriage, tailstock, and bed, each serving crucial roles in the machining process.

- ⚙️ The headstock houses the spindle, which rotates the workpiece and includes gears to control speed.

- 📏 The carriage (Eretan) manages the cutting tool's movement, allowing for precise adjustments during machining.

- 📍 The tailstock provides support for centers and assists in drilling operations on the lathe.

- 🔩 Bench lathes are portable and ideal for small workpieces, while standard lathes are commonly used in industrial settings.

- 💪 Heavy-duty lathes can handle large and heavy materials, making them suitable for industries like shipbuilding and mining.

- 🔄 Vertical lathes feature a vertical spindle for specific machining tasks and are useful for larger workpieces.

- 🔒 Various workholding methods, including chucks, collets, and face plates, are used to secure workpieces during the machining process.

Q & A

What is a lathe machine and what is its primary function?

-A lathe machine, commonly known as a turning machine, is a type of machine tool used to shape materials, primarily metals and woods, into cylindrical profiles by rotating the workpiece against a cutting tool.

How does the turning process work in a lathe machine?

-The turning process involves securing a workpiece on the spindle of the lathe, which is then rotated while a cutting tool is directed towards it, allowing the material to be shaved off and shaped into the desired profile.

What are the main components of a standard lathe machine?

-The main components of a standard lathe machine include the headstock, carriage (which includes the longitudinal and cross slides), tailstock, and bed, which supports the machine and provides stability.

What role does the headstock play in a lathe machine?

-The headstock houses the main spindle and the motor, allowing for the rotation of the workpiece and enabling the adjustment of cutting speeds through a series of gears.

Can you explain the different types of movements the carriage can perform?

-The carriage can perform three types of movements: longitudinal movement (along the length of the workpiece), cross movement (across the diameter), and vertical movement (if equipped with an additional tool post).

What is the function of the tailstock in a lathe machine?

-The tailstock serves as a support for the other end of the workpiece, allowing for the use of centers and drilling tools. It can be adjusted to accommodate different lengths of workpieces.

What are the different classifications of lathe machines based on size?

-Lathe machines can be classified into several categories: bench lathes for small parts, standard lathes for medium-sized work, and heavy-duty lathes for large and heavy workpieces, such as those used in shipbuilding and mining.

What is the significance of the bed of a lathe machine?

-The bed of the lathe machine supports the entire assembly, ensuring stability during operations. Its smooth surface is essential for precise movement and machining quality.

What are some common clamping methods used in lathe machines?

-Common clamping methods include chucks (with three to six jaws), collets (which offer better precision), and face plates for complex workpieces that cannot be held by traditional chucks.

How has the design of lathe machines evolved over time?

-The design of lathe machines has evolved from manual turning methods used in ancient times to advanced, automated systems integrated with computer numerical control (CNC) technology, enhancing precision and efficiency in machining.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)