PENETRANT TESTING & MAGNETIC PARTICE LINSPECTION | POLITEKNIK NEGERI BATAM

Summary

TLDRThe video discusses the process and tools used in magnetic particle testing and penetration testing. It begins by introducing the equipment, such as brushes, measuring tools, and chemical sprays, used for surface preparation and defect detection. The video explains step-by-step how to clean the specimen, apply magnetic particles or liquid penetrants, and observe defect indications like linear or rounded flaws. The team demonstrates the testing methods, ensuring thorough inspection of welds and surfaces to identify potential defects in materials.

Takeaways

- 🔍 The team is discussing magnetic particle testing and penetration testing methods.

- 🔧 Tools and materials introduced include brushes, rulers, parting agents, and measuring instruments.

- 🧼 Specimen preparation involves cleaning the surface with a brush to remove residue.

- 😷 Safety precautions include wearing masks due to the toxic nature of some materials used.

- 📏 After cleaning, measurements are taken to detect potential welding defects using magnetic methods.

- 🧲 Magnetic particles gather in areas with defects, which are then analyzed to identify welding flaws.

- 🛠 Linear defects are longer than three times their width, while rounded defects are smaller in comparison.

- 🧪 Penetration testing involves applying liquid penetrants, waiting for 10 minutes, then cleaning the specimen.

- 💡 After cleaning, a developer is applied to highlight defects, with the team analyzing linear and rounded defects.

- 📊 The final analysis compares defect sizes and shapes, with both linear and rounded defects documented in detail.

Q & A

What is the purpose of the magnetic particle test described in the script?

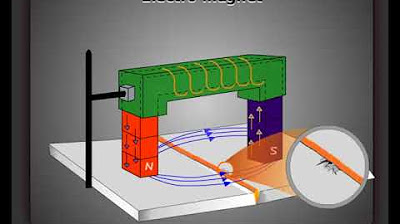

-The magnetic particle test is used to detect surface and slightly subsurface defects in ferromagnetic materials. It works by inducing a magnetic field and applying magnetic particles to identify irregularities or defects in the material.

What are the main tools and materials required for the magnetic particle test?

-The tools and materials include magnetic testing equipment, magnetic particles (dry or in liquid form), a brush for cleaning the specimen, rulers for measurement, contrast agents, and a cleaner or thinner to remove impurities.

Why is cleaning the specimen important before starting the test?

-Cleaning the specimen ensures that any contaminants or residues are removed from the surface, which allows for accurate detection of defects during the magnetic particle testing.

How are the magnetic particles applied during the test?

-The magnetic particles are sprayed onto the surface of the specimen at an angle of 30 degrees. This allows the particles to settle into any surface defects or irregularities that are magnetically detected.

What is the purpose of the developer used in the penetration test?

-The developer helps to bring out any penetrant that may have entered surface defects. It enhances visibility by drawing the penetrant to the surface, allowing inspectors to detect defects like cracks or gaps.

How are defects identified during the test?

-Defects are identified when magnetic particles gather in specific areas where there are cracks, voids, or other irregularities. These areas are inspected for patterns, such as rounded or linear defects, to determine the type and severity.

What is the difference between rounded and linear defects in the test results?

-Rounded defects are smaller and typically less than three times the width of the defect, whereas linear defects are longer and more severe, with a length greater than three times the width.

How long does it take to wait between cleaning the specimen and applying the penetrant?

-After cleaning the specimen, the script specifies that a waiting period of about five minutes is required before applying the liquid penetrant to ensure the surface is properly prepared.

What safety precautions are mentioned in the script when conducting the test?

-The script emphasizes the use of masks when applying certain chemicals like sprays, as they can be toxic or harmful if inhaled during the testing process.

How is the result of the magnetic particle test interpreted after development?

-After applying the developer and waiting for around 15 minutes, the results are interpreted by looking for visible indications of defects. Pink or other colored marks often signify defects, which are then measured and classified as either rounded or linear.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)