Fractional Distillation: Separation Technique of Miscible Liquids

Summary

TLDRThis video introduces fractional distillation, a separation technique for miscible liquids with close boiling points, such as methanol and ethanol. Commonly used in industries like oil refining and pharmaceuticals, it involves heating a mixture, where the liquid with the lower boiling point vaporizes first. The fractionating column enhances separation by condensing higher boiling point vapors. Vapors are cooled by a condenser and collected in a flask. The video highlights its applications in essential oil production, alcohol, and water purification. Viewers are encouraged to like, share, and subscribe for more scientific content.

Takeaways

- 🔬 Fractional distillation is a powerful separation technique used for separating miscible liquids.

- 🌡️ The process is ideal for separating liquid mixtures with close boiling points, like methanol (65°C) and ethanol (78°C).

- 🛢️ It is widely used in industries like refining crude oil to obtain products such as gasoline and diesel.

- ⚗️ Key apparatus includes a distillation flask, fractionating column, thermometer, condenser, and collecting flask.

- 🏗️ Fractionating columns allow for multiple vaporization-condensation cycles for more precise separation.

- 🌡️ A thermometer monitors the vapor temperature, which is critical for identifying the boiling point of each component.

- 💧 The condenser plays a key role in turning vaporized substances back into liquid form for collection.

- 🧪 Boiling stones are added to prevent superheating and ensure smooth heating during the distillation process.

- 🍃 Fractional distillation is also used in the production of essential oils, alcoholic beverages, and water purification.

- 📊 This technique is crucial for obtaining pure substances, especially in pharmaceuticals and other precise industries.

Q & A

What is fractional distillation?

-Fractional distillation is a separation technique used to separate miscible liquids with close boiling points by heating the mixture and condensing the different vapors based on their boiling points.

How does fractional distillation differ from simple distillation?

-Fractional distillation differs from simple distillation in that it includes a fractionating column, which allows for multiple vaporization-condensation cycles, enabling the separation of substances with closer boiling points than simple distillation can handle.

What types of liquids can be separated using fractional distillation?

-Fractional distillation is used to separate miscible liquids, meaning liquids that mix together. An example is the separation of water and alcohol, or methanol and ethanol, which have close boiling points.

What role does the fractionating column play in fractional distillation?

-The fractionating column contains materials like beads that help condense vapors with higher boiling points back into the distillation flask, while allowing lower boiling point vapors to pass through. This creates multiple vaporization-condensation cycles for better separation.

Why is a thermometer essential in fractional distillation?

-A thermometer is used to monitor the temperature of the vapor, which helps identify when each component of the mixture reaches its boiling point and begins to vaporize. This information is crucial for accurately collecting each fraction.

How is the condenser used in fractional distillation?

-The condenser cools the vapor from the distillation flask back into liquid form, allowing it to be collected in a receiving flask. Efficient cooling improves the yield of the desired product.

What industries commonly use fractional distillation?

-Fractional distillation is widely used in industries such as petroleum refining, where it separates crude oil into products like gasoline and diesel, as well as in the production of essential oils, alcoholic beverages, and pharmaceuticals.

Why are boiling stones used in the distillation flask?

-Boiling stones are added to the distillation flask to ensure smooth heating by promoting even boiling, preventing the liquid from superheating and 'bumping' during the distillation process.

What is the purpose of maintaining a temperature gradient within the fractionating column?

-A temperature gradient is maintained to allow different components to condense at various levels in the column, enabling the gradual separation of the mixture based on boiling points, which results in more refined fractions.

What is the importance of efficient cooling in fractional distillation?

-Efficient cooling ensures that the vaporized components are properly condensed back into liquid form, leading to a higher yield of the desired fraction. This is achieved by allowing water to enter from the bottom of the condenser.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Separating Liquids by Distillation

Simple and fractional distillations | Chemical processes | MCAT | Khan Academy

GCSE Chemistry - Fractional Distillation and Simple Distillation #50

Simple Distillation and Fractional Distillation

Simple Distillation | #aumsum #kids #science #education #children

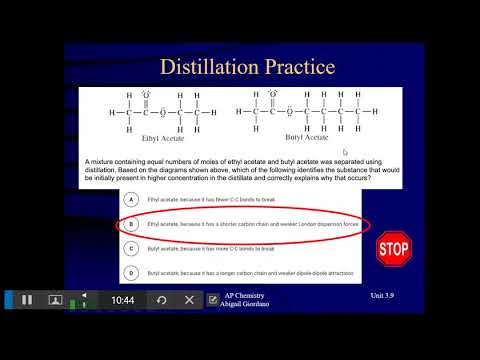

Unit 3.9 - Separation of Solutions and Mixtures

5.0 / 5 (0 votes)