Suction Pump Installation | Piping

Summary

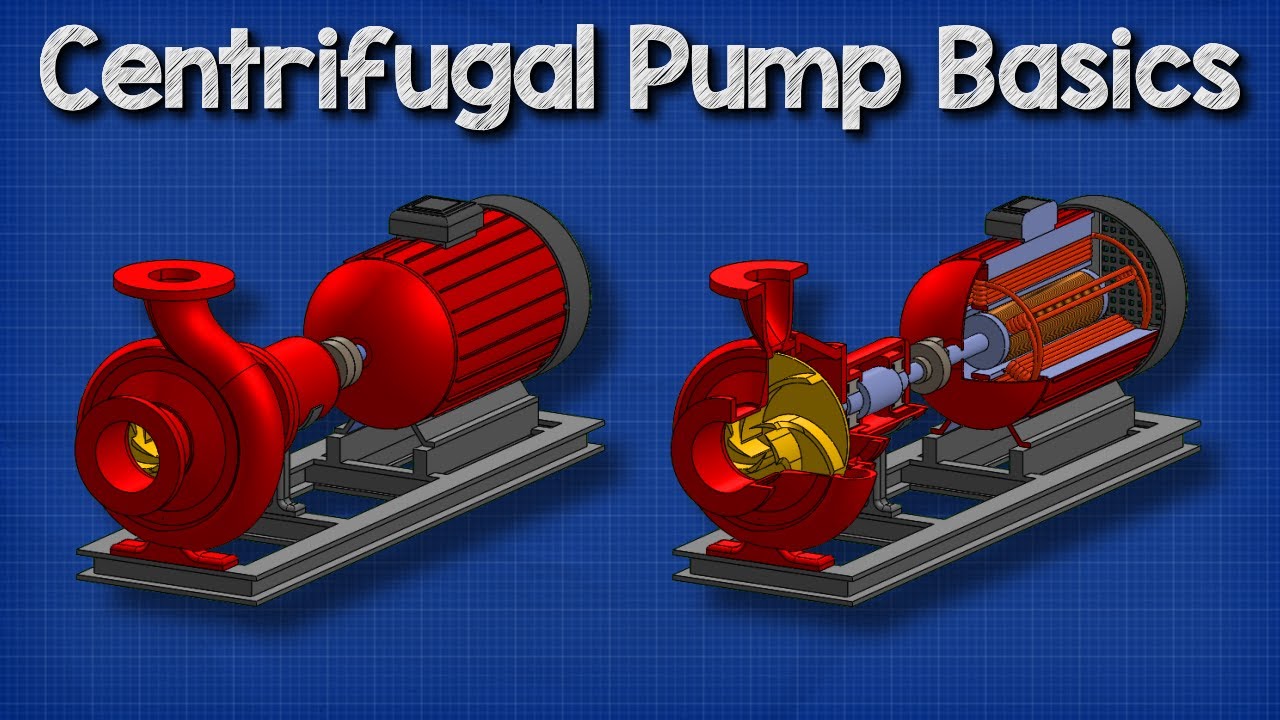

TLDRThis video serves as a general reference and guide for the installation of centrifugal pumps. It covers key steps like planning the foundation, aligning and supporting piping, installing suction and discharge lines, and ensuring proper pump and motor alignment. The guide also highlights essential checks such as ensuring airtight suction, proper reducer fittings, and using reverse dial gauges or laser tools for alignment. Pre-operational checks include flushing cooling lines, ensuring correct wiring, and testing the pump's manual rotation. The video emphasizes the importance of accurate setup to prevent damage and ensure efficient pump operation.

Takeaways

- 🔧 Always refer to the product manual before installing the pump for detailed guidance.

- 🛠️ Ensure the pump foundation is level, sturdy, and capable of absorbing vibrations.

- 🔩 All piping should be anchored independently of the pump to avoid strain on the pump casing.

- 📐 Proper alignment of suction piping is essential, with all connections carefully aligned axially and angularly.

- 💧 Suction pipes should be airtight and sized to maintain liquid velocity under 2 m/s, with a continuous rise towards the pump inlet.

- 🧱 Use an eccentric reducer for joining the suction pipe to the pump, ensuring the inclined side faces downwards.

- 📊 Install a vacuum gauge in the suction line to monitor performance, especially under negative suction conditions.

- 🔄 In case of flooded suction, a pressure gauge should be installed, and liquid velocity should not exceed 3 m/s.

- ⚙️ Align the pump and motor using precision tools like a dial gauge or laser, ensuring proper coupling and alignment.

- 🛑 Before operation, conduct pre-operational checks, including flushing cooling lines, refilling bearing housing oil, and ensuring there are no leaks.

Q & A

What is the first step to take before installing the centrifugal pump?

-Before installing the centrifugal pump, it is crucial to read the product manual to gain an in-depth understanding of how the pump works and how to install it properly.

How should the foundation for the pump be prepared?

-The foundation must be well-prepared, substantial enough to support the pump's weight, and absorb any vibrations. It should also be perfectly straight without any inclination or tilting.

Why is it important to anchor and support the piping independently of the pump?

-Piping must be anchored and supported independently to avoid putting strain on the pump casing, as unsupported pipes can cause the casing to crack or deflect due to bearing the weight of the pipes.

What are the requirements for suction piping in a negative suction condition?

-For negative suction conditions, the suction piping should be properly aligned and supported separately. The suction pipe should be at least one commercial size larger than the pump inlet, with a continuous rise to the suction inlet and airtight connections.

What is the role of an eccentric reducer in the pump suction line?

-The eccentric reducer joins the straight length of the pipe to the pump line, with the inclined side positioned at the bottom. This design helps prevent air pockets and maintain a smooth flow of liquid to the pump.

What is the recommended mesh size for the suction strainer, and why is it important?

-The mesh size of the suction strainer should be large enough to filter out solid particles that could clog the impeller. It should have an area at least four times the suction pipe area.

What precautions should be taken when installing a pump with positive suction (flooded suction)?

-For positive suction, ensure the suction pipe has a descending inclination, install an isolation valve, and provide a pressure gauge tapping in the suction line to monitor pressure changes.

Why is it important to recheck the pump's alignment after bolting the pipes?

-Rechecking alignment after bolting ensures that the piping doesn't put stress on the pump casing. Misalignment can cause operational issues and lead to damage over time.

What are the steps involved in checking the pump and motor alignment?

-The pump and motor are aligned using a reverse dial gauge or laser alignment tool. Once aligned, the piping is bolted, and alignment readings are rechecked to ensure they are consistent.

What should be done during preoperational checks before starting the pump?

-Preoperational checks include flushing cooling water lines, draining and refilling the bearing housing oil, checking the wiring for correct motor rotation, testing the movement manually, and ensuring there are no leaks in the pump system.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

POMPA | Definisi Pompa | Jenis-jenis Pompa

Mengenal Jenis Pompa : Centrifugal Pump

Types of Pumps | All in One Guide to Industrial Pump Types

Centrifugal Pump Basics I Definition I Working I Velocity Triangle I Work Done I Head I Efficiency

Yuk Belajar Tentang Pompa-Pompa di atas Kapal (Part 1) - Lilin Tua #pompa #kapal #belajar #pelaut

5.0 / 5 (0 votes)