Connect 3D Printed Parts | Design for Mass Production 3D Printing

Summary

TLDRThis video script offers a comprehensive guide on various methods to join larger 3D printed parts together. It begins with the basic peg and hole system, advising against round pegs due to their weaknesses, and suggests using a square peg diagonally for better dimensional precision and strength. The script then introduces slab and slot connectors for low-profile applications and S-brackets for a precise and strong connection. It also touches on snap fits, which are quick and easy but may require careful design for robustness. The video concludes by highlighting that these are just a few of the many ways to combine parts and encourages viewers to explore more methods, including embedding features into the parts themselves, for optimal 3D printing design.

Takeaways

- 🔩 There are various methods to join parts together, such as screws, glue, or designing in fasteners for snapping.

- 📐 For 3D printing larger parts from smaller ones, basic connectors are essential for assembly.

- 🚫 Avoid using round pegs and holes due to potential dimensional inaccuracy and weak horizontal printing.

- 💠 Use a square peg and diagonal orientation to create a diamond hole and peg for dimensional precision and strength.

- 🔨 The diamond peg design ensures no overhang, allowing for horizontal printing and a strong connection through friction.

- 🔲 For low-profile connections, consider using a slab and slot system with tapered ends for a secure fit.

- 🔗 Pegs can have gaps due to flexing; consider alternatives for a more precise and robust connection.

- 🔗 Use an S-bracket for a simple and symmetrical connection that can be replicated throughout a design.

- 🔗 Snap fits with a double-sided C clamp can provide a fast and easy connection but may be less robust.

- 🔧 Designing connectors directly into parts can eliminate the need for third-party inserts and can be more efficient.

- 📚 There are many ways to combine parts, and additional resources are available for more advanced techniques.

Q & A

What are some common methods for joining two parts together?

-Common methods for joining parts include screwing, gluing, and designing fasteners into the parts to enable snapping together.

Why is using a round peg and a round hole not recommended for 3D printed parts?

-A round hole can sag and be dimensionally imprecise, and a round peg cannot be printed horizontally in a strong orientation, making it prone to snapping off.

What is the recommended alternative to a round peg and hole for joining 3D printed parts?

-A square peg turned diagonally to form a diamond shape is recommended, as it ensures dimensional precision and can be printed horizontally for strength.

What is the issue with pegs when joining parts together?

-Pegs can have a big gap between parts because the broad face can flex, causing the outer edges to come together but then pop back loose, resulting in a gap.

What is a low-profile connecting option for 3D printed parts?

-A slab and slot mechanism is a low-profile connecting option that is easy to implement and reliable.

Why should the ends of a peg be tapered and rounded in a slab and slot mechanism?

-Tapering and rounding the ends of a peg allow it to slide in easily and then tighten as it goes in, connecting with the walls of the part more effectively.

What is an S bracket and how is it used to join parts?

-An S bracket is a small piece designed with a hole to slide into a part and then into a slot, where it snaps into a small slot inside the part, providing a precise joining position.

What is a snap fit and how does it differ from other joining methods?

-A snap fit is a double-sided C clamp that is pressed into a slot and then slots into holes inside the part. It is easy and intuitive but can be less robust due to the flexing required for the mechanism.

Why might a snap fit be less reliable than other joining methods?

-A snap fit might be less reliable because it requires precise design to allow for enough pressure and correct latch contact, and it involves pressing parts together rather than squeezing them for an overcentered clamp.

What are some factors to consider when choosing a joining method for 3D printed parts?

-Factors to consider include the ease of use, strength of the connection, precision, and whether the method requires additional pressure or training.

Are there other videos that discuss embedding joining features into 3D printed parts?

-Yes, there is another video that covers how to embed joining features into parts themselves, eliminating the need for a third insert peg.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

KIESETT az első KERÉK a millió km-es TAXIN ?

How To Start A Successful Jewelry Business On A BUDGET

How Robots Use Maths to Move

3D Printing Basics: Parts names, care, and filament types! (Ep4)

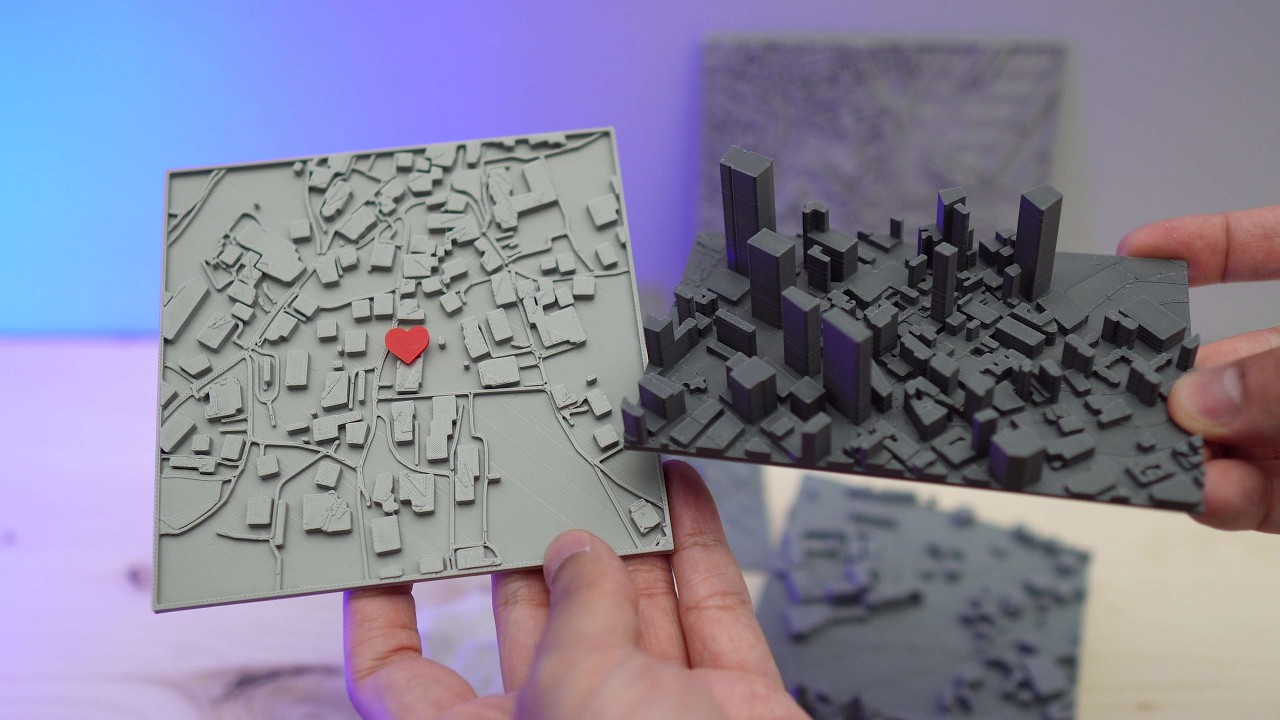

How to 3D Print your own Cityscapes and Terrains (FREE Method)

3D printing bolt and thread in horizontal or vertical position - strength test

5.0 / 5 (0 votes)