Lean Manufacturing - Standardized Work

Summary

TLDRStandardized work is a systematic approach to efficiency in production, detailing step-by-step processes to eliminate waste and ensure consistency. It involves creating and adhering to Standard Operating Procedures (SOPs) that outline the best practices for tasks, promoting continuous improvement and knowledge sharing. This method not only maintains consistent product development but also ensures that expertise is preserved within the organization, leading to improved safety, quality, and efficiency.

Takeaways

- 📘 Standardized work is a systematized approach to tasks, ensuring efficiency and consistency in production processes.

- 🔍 The primary goal of standardized work is to outline clear procedures for operators to follow, leading to consistent outcomes.

- 🛠️ Standard operating procedures (SOPs) are key tools for developing, documenting, and using standardized work processes.

- 🗣️ Effective SOPs require clear communication and information sharing about the most efficient methods for task completion.

- 🔄 SOPs should be living documents, subject to continuous improvement and evolution over time.

- 👥 Standardized work promotes collective documentation and consolidation of best practices within an organization.

- 🚫 It discourages individualized methods that can lead to process variability and inconsistency when personnel change.

- 🧠 By standardizing work, organizations prevent reliance on memory and ensure that expertise is maintained and passed on.

- 🏫 Standardized work ensures consistent training results, which is crucial for maintaining quality and efficiency.

- 🔄 The differentiation between standardization (conforming to industry standards) and standardized work (consistent task performance) is important.

- 🔗 Standardized work improves safety and quality by eliminating ambiguity and inconsistency in processes.

Q & A

What is standardized work?

-Standardized work is a detailed, documented, and visual system of steps within a process sequenced without waste, aiming to achieve the most efficient level of production. It involves clear procedures for operators, combining methods, tools, and documents to describe the best way to execute a process consistently.

What is the main goal of standardized work?

-The main goal of standardized work is to maintain consistent working practices, which ultimately results in consistent product development by showing how the job is done with clear procedures.

How are standard operating procedures (SOPs) related to standardized work?

-Standard operating procedures (SOPs) are the most common way to develop, document, and use standardized tasks. They establish the most efficient method that can be replicated when completing tasks and are essential for promoting continual improvement to the standards.

Why is it important for SOPs to be living documents?

-SOPs should be considered living documents because they evolve over time, allowing the baseline upon which processes stand as the standard to be improved. This ensures that the standards remain current and adaptable to new best practices.

How does standardized work help in maintaining expertise within an organization?

-Standardized work ensures that expertise is maintained within the organization by documenting information collectively and consolidating practices. This prevents the loss of skills over time and ensures that tasks can be performed consistently, even when personnel change.

What is the difference between standardization and standardized work?

-Standardization is the process of conforming to a standard within a given industry, providing brand recognition and consistency, such as in manufacturing practices or product appearances. Standardized work, on the other hand, involves personnel performing tasks in the same way all the time, eliminating ambiguity and inconsistency within the process.

How does standardized work improve safety and quality?

-Standardized work improves safety and quality by having repeatable processes that eliminate ambiguity and inconsistency. It also encourages the use of documents like safety procedures, which ensure that tasks are performed correctly and safely every time.

What are some examples of standardized work in practice?

-Examples of standardized work include specific tasks and procedures like how to install a bolt, line setup changeover processes, and safety procedures like lockout tagout. These ensure that tasks are performed in a consistent and efficient manner.

How does standardized work increase efficiency?

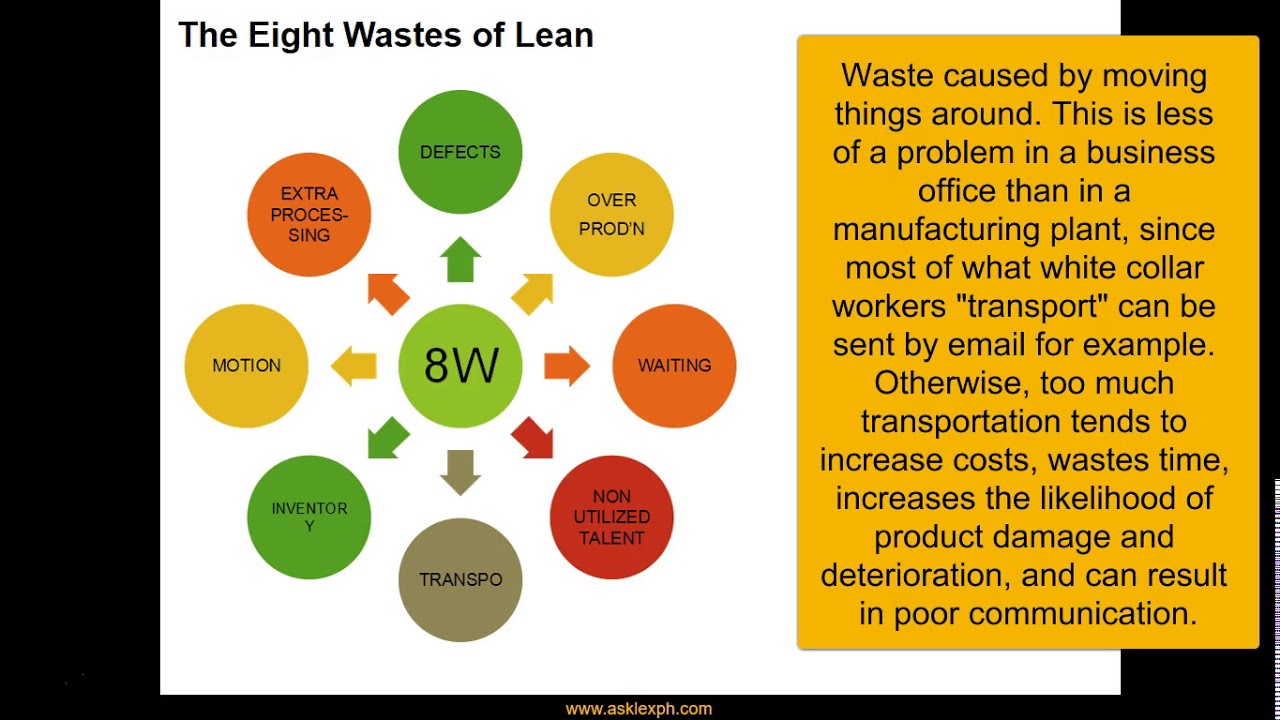

-Standardized work increases efficiency by eliminating waste through repeatable processes. It ensures that tasks are performed in the most efficient way possible, reducing the need for rework and minimizing errors.

What role do documents play in standardized work?

-Documents play a crucial role in standardized work by providing detailed, documented, and highly visible systems. They include product drawings, work instructions, tooling layout drawings, and calibration instructions, which help in maintaining consistency and ensuring that tasks are performed correctly.

Why is it important to differentiate between individual methods and standardized work?

-Differentiating between individual methods and standardized work is important because while individual methods can lead to great ideas, companies need to document and consolidate practices collectively to ensure consistency and prevent process alteration when personnel change.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)