Bizzare Shifter

Summary

TLDRIn this inventive project, the creator guides viewers through the process of integrating a Nixie tube into a car's shifter knob to display the current gear. The tutorial covers the technical challenges, such as the high voltage requirement of Nixie tubes and the use of an 'Easy Nixie' driver board to simplify the process. It also includes a sponsorship mention for PCBWay, a resource for electronic project components. The video delves into the intricacies of 3D modeling and printing the shifter knob to accommodate the Nixie tube, complete with detailed assembly instructions. The project is a blend of retro-futuristic aesthetics and modern technology, aiming to inspire viewers to experiment with Nixie tubes in their own unique applications.

Takeaways

- 🛠️ The video demonstrates how to integrate a Nixie tube into a car shifter knob to display the current gear.

- 📺 The presenter has previously experimented with various displays inside shifter knobs, including LED matrices and LCD screens.

- ⚡ Nixie tubes require high voltage (around 200V) to operate, unlike the 5V used for Arduino Uno projects.

- 🔗 The 'Easy Nixie' board is introduced as a key component to simplify controlling Nixie tubes with an Arduino.

- 🌐 PCBWay is highlighted as a sponsor, offering PCB manufacturing services and a special deal for the audience.

- 🔌 The video provides detailed pin connections for setting up the Easy Nixie board with an Arduino Uno.

- 💻 The Arduino Library for the Easy Nixie board is downloaded from GitHub, and an example sketch is used to test the setup.

- 🔩 The presenter discusses the compatibility of different Nixie tube types with the Easy Nixie board.

- 🏗️ A 3D printed shifter knob is designed to house the Nixie tube, with adjustments made for a proper fit.

- 🎨 Fusion 360 is used for 3D modeling the shifter knob and Nixie tube enclosure, with iterative design to achieve a good fit.

- ⏱️ Time-lapse footage is shared of the 3D printing process, showcasing the final product's assembly.

Q & A

What is the main project idea presented in the video?

-The main project idea is to integrate a Nixie tube into a shifter knob to display the current gear, creating a retro-futuristic automotive accessory.

Why can't Nixie tubes be directly connected to an Arduino Uno?

-Nixie tubes require a high voltage of around 200 volts to operate, whereas the Arduino Uno operates on 5 volts, so they cannot be connected directly.

What is the 'secret source' mentioned for controlling Nixie tubes?

-The 'secret source' is a driver board called 'Easy Nixie' which simplifies the control of Nixie tubes with an Arduino.

How can viewers get 10 PCBs for free from PCBWay?

-Viewers can get 10 PCBs for free by using the link provided in the video description and paying only for shipping.

What is the name of the Kickstarter project that the Easy Nixie board originated from?

-The Kickstarter project that the Easy Nixie board originated from is not explicitly named in the transcript, but it is mentioned that the board started as a Kickstarter project and was successfully backed.

How can one find the Arduino library for the Easy Nixie board?

-The Arduino library for the Easy Nixie board can be found on a GitHub page linked in the Kickstarter project description.

What types of Nixie tubes are mentioned in the video?

-The video mentions several types of Nixie tubes including the 12a, 12b, 15a, 15b, and 17, each with different characters and functionalities.

What modification did the creator make to the shifter knob design to fit the Nixie tube?

-The creator made the bottom piece of the shifter knob hollow and redesigned it to screw together with the top piece, creating more space to fit the Nixie tube.

How did the creator approach 3D printing the Nixie tube holder?

-The creator approached 3D printing the Nixie tube holder by first creating a simple model to test the fit, then iterating on the design to accommodate the Nixie tube, and finally combining it with the shifter knob shape.

What challenges did the creator face while 3D printing the final design?

-The creator faced challenges with support removal and overhangs during 3D printing, which were addressed by adjusting support settings and using a special support filament.

Are Nixie tubes still being manufactured, and if not, what are the alternatives mentioned?

-Nixie tubes are not being manufactured anymore, but there are companies that are producing them again, and alternatives like fake Nixie tube clocks are also mentioned.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Lampu tidur sederhana lampu hias dari botol bekas dan sendok plastik

Cómo hacer una radio casera (sin pilas) (Experimentos Caseros)

Setting Up Vite and React for Chrome Extension Development

Unity Logitech Steering Wheel usage

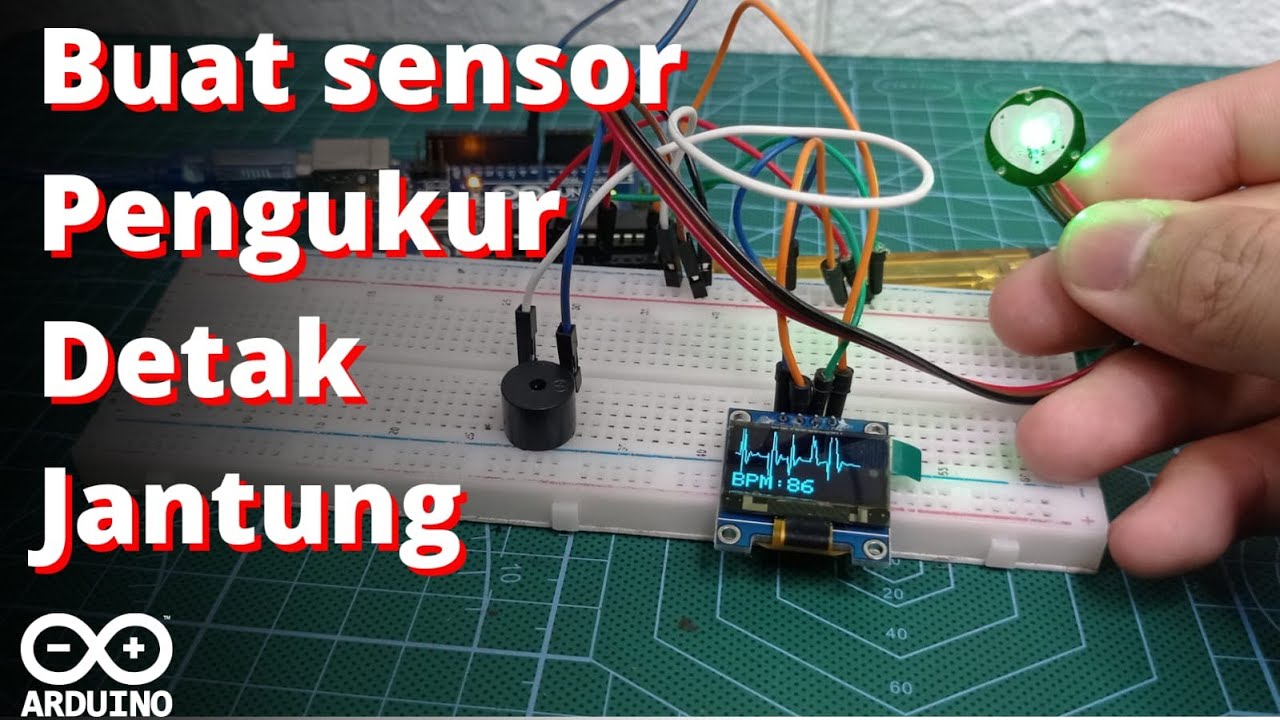

Buat Sensor Pengukur detak Jantung || Heart Rate Sensor Arduino || Pulse sensor [#Tutorial12]

FlutterFlow — Connecting and Configuring Firebase to Your App | FlutterFlow NoCode Training 2022

5.0 / 5 (0 votes)