Mechanical Properties of Materials.

Summary

TLDRThis tutorial delves into the mechanical properties of materials, crucial for designing tools, machines, and structures. It covers properties like strength, stiffness, elasticity, plasticity, ductility, malleability, toughness, brittleness, hardness, and more. The video explains these through tensile tests and stress-strain diagrams, highlighting their significance in industrial applications and how they're influenced by a material's structure and imperfections.

Takeaways

- 🔩 The mechanical properties of materials are crucial for designing tools, machines, and structures.

- 📏 Mechanical properties are influenced by a material's crystal structure, bonding forces, and imperfections within the crystal or at grain boundaries.

- 🏗️ Main mechanical properties include strength, stiffness, elasticity, plasticity, ductility, malleability, toughness, brittleness, hardness, formability, castability, and weldability.

- 🔍 Tensile tests and stress-strain diagrams are instrumental in understanding these properties.

- 🔺 Elasticity allows materials to regain their shape after deformation when external forces are removed.

- 📐 The proportional limit is the maximum stress a material can endure without deforming at a non-uniform rate.

- 🔼 The elastic limit is the highest stress a material can withstand without permanent deformation.

- 💪 Yield point is the stress level at which a material begins to deform permanently.

- 🏋️♂️ Strength is a material's ability to resist external forces without breaking or yielding.

- 🏗️ Stiffness is a material's resistance to deformation under stress, often measured by the Young's modulus of elasticity.

- 🧱 Plasticity refers to a material's ability to retain deformation permanently after the load is removed.

- 🧵 Ductility is the property that allows a material to be drawn into wire without breaking, often measured by elongation and reduction in area.

- 🛠️ Malleability is the capacity of a material to be hammered or rolled into thin sheets without cracking.

- ✂️ Hardness is the resistance of a material to cutting, scratching, or deformation.

- 💔 Brittleness is the tendency of a material to break with little or no deformation, as opposed to ductility.

- 🐌 Creep is the slow, permanent deformation of a material under constant stress at high temperatures over time.

- 🔄 Formability is the ease with which a metal can be shaped through plastic deformation without damage.

- 🗽 Castability is the ease of casting a metal into different shapes and sizes.

- 🔗 Weldability is the ability to join metals by fusion, with or without pressure or filler metal.

Q & A

What are the mechanical properties of materials?

-The mechanical properties of materials are characteristics that determine how a material responds to applied forces. They include strength, stiffness, elasticity, plasticity, ductility, malleability, toughness, brittleness, hardness, formability, castability, and weldability.

Why are mechanical properties important in industrial applications?

-Mechanical properties are crucial in industrial applications because they influence the design of tools, machines, and structures. They determine how materials will behave under various mechanical forces and loads, ensuring safety, reliability, and efficiency in their use.

How do the crystal structure and bonding forces affect the mechanical properties of materials?

-The crystal structure and bonding forces directly influence the mechanical properties of materials because they determine the resistance to deformation and the ability to withstand loads. The nature and behavior of imperfections within the crystal structure or at grain boundaries also play a significant role.

What is elasticity, and how is it measured?

-Elasticity is the property of a material to regain its original shape after deformation when the external forces are removed. It is measured by observing how the material behaves under stress and strain, and it can be quantified using the stress-strain diagram.

What is the proportional limit, and why is it significant?

-The proportional limit is the maximum stress under which a material maintains a perfectly uniform rate of strain to stress. It is significant because it represents the upper limit of the linear relationship between stress and strain, beyond which the material may no longer behave elastically.

What is the yield point, and how does it relate to the material's behavior?

-The yield point is the stress at which a material begins to flow or change shape permanently. It marks the end of elastic behavior and the beginning of plastic behavior, indicating the stress level at which the material no longer returns to its original shape after the load is removed.

How is strength defined in the context of mechanical properties?

-Strength is defined as the ability of a material to resist externally applied forces without breaking down or yielding. It is the internal resistance offered by a material to an applied force, and it determines the material's ability to withstand stress without failure.

What is stiffness, and how does it differ from elasticity?

-Stiffness is the ability of a material to resist deformation under stress. It differs from elasticity in that stiffness refers to the resistance to deformation, while elasticity refers to the ability to return to the original shape after deformation.

How is ductility measured, and what does it indicate about a material?

-Ductility is measured by the percentage of elongation and percent reduction in area a material can undergo before breaking. It indicates the material's ability to be drawn into wire or deformed into different shapes without breaking, which is important for forming and shaping processes.

What is malleability, and how does it relate to ductility?

-Malleability is the ability of a material to be flattened into thin sheets under heavy compressive forces without cracking. It is a special case of ductility that allows materials to be rolled or hammered into thin sheets, and it is important for processes like sheet metal working.

Why is hardness an important mechanical property for metals?

-Hardness is an important property because it indicates a metal's resistance to wear, scratching, and deformation. A harder metal can cut or make an impression on a softer metal, which is crucial for applications where resistance to abrasion and durability are necessary.

What is brittleness, and how does it affect the material's performance under load?

-Brittleness is the property of a material to break with little or no permanent deformation when subjected to tensile loads. Brittle materials snap off without significant elongation, which can lead to failure under certain loading conditions, making it a critical property to consider in material selection.

What is creep, and how can it affect the performance of a metal part?

-Creep is the slow and permanent deformation that occurs in a metal part when subjected to a high constant stress at high temperatures for an extended period. It can lead to the formation of cracks and eventual failure, affecting the long-term performance and reliability of the part.

How is formability defined, and what factors affect it?

-Formability is the ability of a metal to undergo plastic deformation without being damaged. Factors affecting formability include the crystal structure of the metal, grain size, and whether the working is done hot or cold. Metals with small grain sizes are suitable for shallow forming, while those with larger grains are suitable for heavy forming.

What is castability, and which metals are known for their good castability?

-Castability is the property of a metal that indicates how easily it can be cast into different shapes and sizes. Metals like cast iron, aluminium, and brass are known for their good castability, which is important for manufacturing processes that involve casting.

How is weldability defined, and what does it signify for metal joining?

-Weldability is the property of a metal that indicates how well it can be joined to similar or dissimilar metals by fusion, with or without the application of pressure and the use of filler metal. Good weldability is essential for efficient metal joining processes, which is crucial in various manufacturing and repair applications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is Materials Engineering?

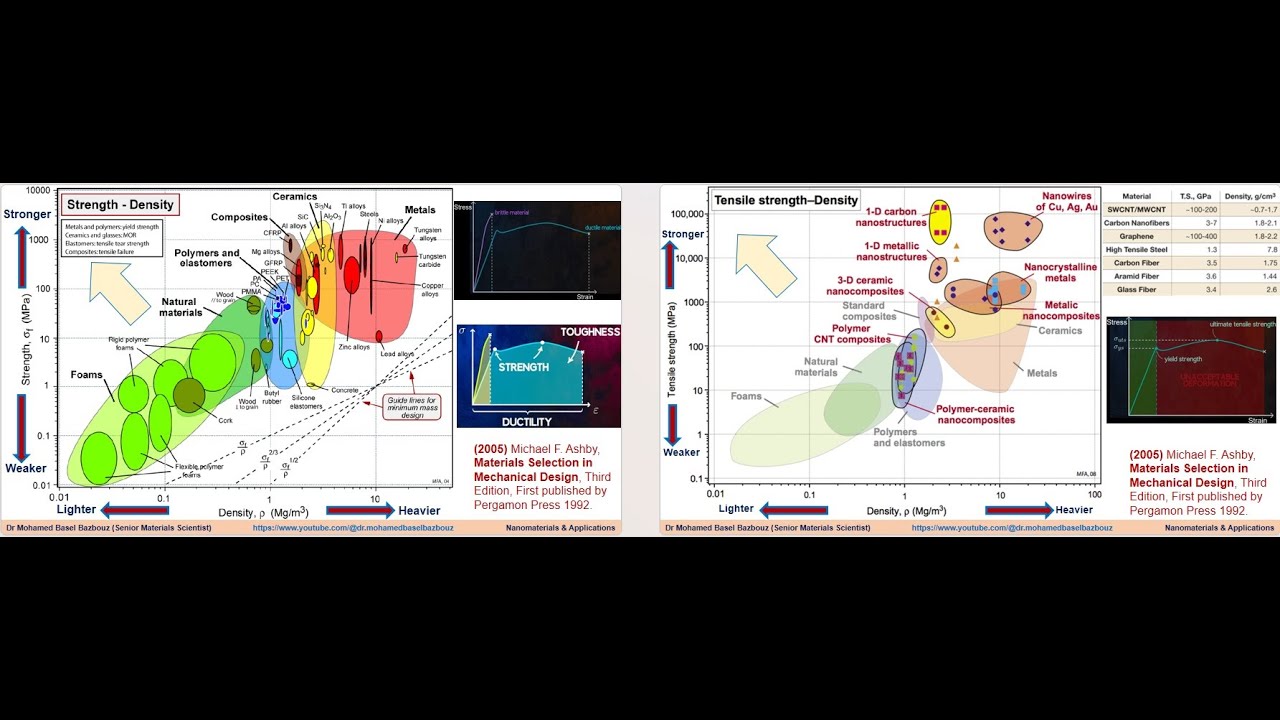

Ashby plots of Strength versus density for materials and nanomaterials المتانة والوزن النوعي

Reaching Breaking Point: Materials, Stresses, & Toughness: Crash Course Engineering #18

Thermoplastics and Thermosetting Plastics | Meaning, difference, uses.

EMC tutorials - Magnetic field shielding

Nanofibers #nanotechnology #nanomaterials #nanotech

5.0 / 5 (0 votes)