Pipe Rack

Summary

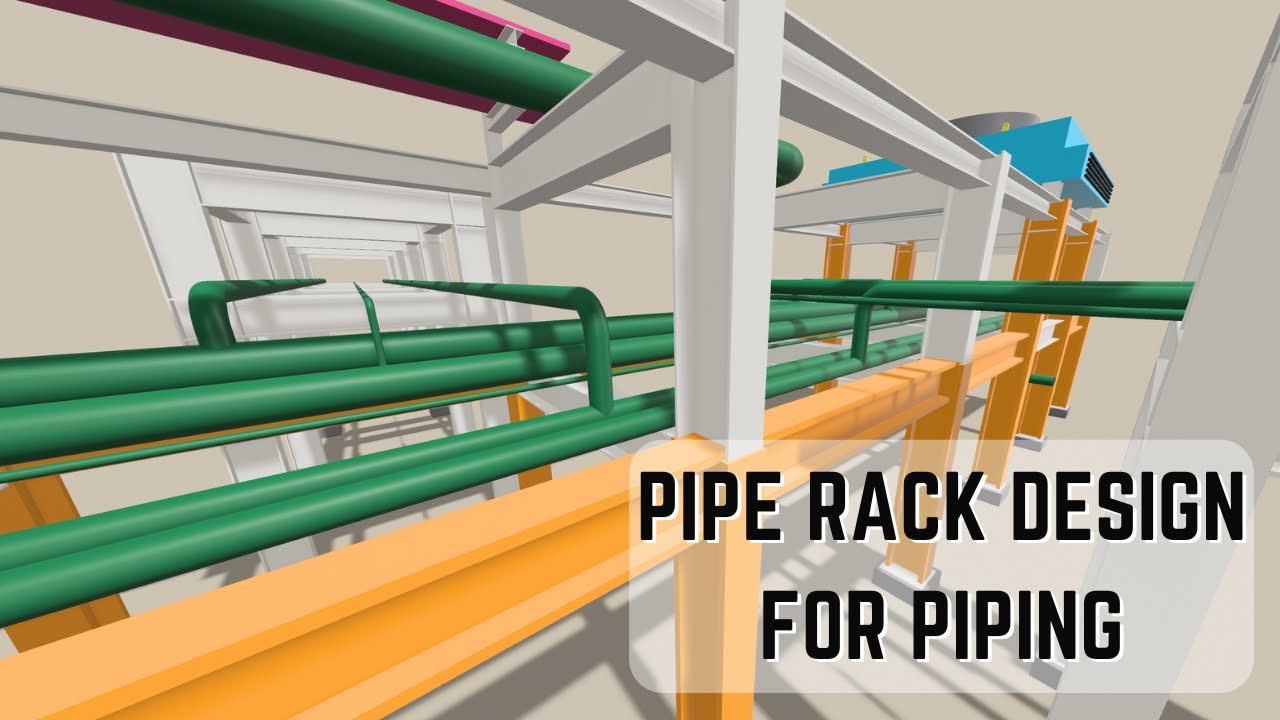

TLDRThis YouTube video, part of the 'Chemical Process Piping' series, delves into pipe rack design and loading data for chemical plants. It covers critical aspects like graph configuration, including height, fast width, and back spacing, and discusses support structures for single or multi-deck setups. The video also addresses the importance of considering equipment support, such as air coolers and fans, and the impact of pipe sizing on the overall system. It explores various construction materials and methods, from reinforced concrete to steel, and touches on the significance of modular structures for ease of construction and maintenance. The video concludes with a call to action for viewers to like, subscribe, and support the channel.

Takeaways

- 🔧 The video discusses contract sizing and loading data for pipe rack design, emphasizing the importance of graph configuration, including best height, fast width, and back spacing.

- 🏗️ Configuration considerations involve overhead or sleeper ways, single or multi-deck placement, and single or multi-column support structures.

- 📏 The height of pipe racks is crucial for maintenance, corrosion prevention, and must be planned in conjunction with the separation of elevated multi-level racks.

- 🛠️ The selection of materials and fabrication methods affects the spacing and design of pipe supports, with options including more closely spaced pipe supports or fewer supports with a modular unit system.

- 🏭 The structural form of pipe racks can be constructed using reinforced concrete, steel, or a combination of both to provide support for equipment and piping.

- ⚙️ Modular pipe racks offer a series of standard units that can be assembled with pipes, cable trays, and equipment, which can be advantageous for remote locations or to save on labor costs.

- 📈 The design and construction of pipe racks involve detailed studies of the total piping systems, including the use of transposition to account for each line on the pipe rack.

- 📊 Load considerations for pipe racks include dead weight, live loads, friction loads, and special attention to unusual loads such as large valves or extensions.

- 🌐 The video highlights the importance of considering seismic loads and friction forces in the design of pipe racks, especially for structures that are part of critical infrastructure.

- 🔩 The design of pipe racks must account for various forces, including longitudinal, transverse, and vertical loads, and should be analyzed using appropriate structural models to ensure stability and safety.

Q & A

What is the main focus of the video?

-The main focus of the video is on contract sizing and loading data for pipe rack design, covering important aspects such as graph configuration, best practices, and considerations for various components of the pipe rack system.

What are the key elements of graph configuration discussed in the video?

-The key elements of graph configuration discussed include the selection of overhead app or a sleeper way, whether it will be single deck or multiple decks, single column support or multi-column support, and the number of columns.

Why is it important to consider the process units themselves when configuring a pipe rack?

-Considering the process units themselves is important to determine whether the pipe rack will support equipment such as air coolers, fans, and other parts, which are crucial for the overall functionality and safety of the system.

What is the significance of pipe sizing in the design of a pipe rack?

-Pipe sizing is significant as it influences the determination of separation between levels of the rack, which is based on the line sizes to be carried on the racks. This requires a detailed study of the total piping systems for the whole plant.

How does the concept of transposition aid in the pipe rack design process?

-Transposition is a study that accounts for each line on each pipe rack, establishing a group sequence and adding an error factor and client's future reserve to determine a minimum effective width for the pipe rack.

What are the different materials and fabrication methods for pipe rack construction mentioned in the video?

-The video mentions three methods for pipe rack construction: reinforced concrete, steel, and steel covered by concrete. Each method has its advantages and disadvantages in terms of time consumption, corrosion resistance, and maintenance requirements.

Why is modular construction considered for pipe racks?

-Modular construction is considered for pipe racks because it allows for parallel construction activities, such as foundation and module fabrication, which can save project costs, especially in remote locations or where labor costs at the site are high.

What are the different types of pipe racks mentioned in the script?

-The script mentions conventional contract systems and continuous pipe racks. Conventional contract systems use two-dimensional frame assemblies, while continuous pipe racks utilize a 3D space-framed arrangement for supporting equipment.

What are the key considerations for data collection during pipe rack design?

-Key considerations for data collection include piping orthographic drawings, vendor prints of equipment, load magnitude and direction, electrical and control systems drawings, underground drawings, and design loads considerations.

How do earthquake loads affect the design of pipe racks?

-Earthquake loads affect the design of pipe racks by requiring the structure to be evaluated for seismic loads in vertical, transverse, and longitudinal directions. The loads generated by pipes, raceways, supported equipment, and the pipe rack structure itself must be considered.

What is the role of transverse beams in the pipe rack structure?

-Transverse beams play a crucial role in resisting all forces, moments, and shears produced by the load combinations. They are generally designed as moment-resisting frames and are part of the frame system analysis.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pipe Rack Design for Piping : Essential Tips for Piping Engineers

Piperack Loading | Different pipe Loads on Piperack | Piping Mantra |

Fundamental of Pipe (Pipeline) for Oil & Gas Engineer - Revised

Unit Operations in Chemical Engineering - Course Trailer

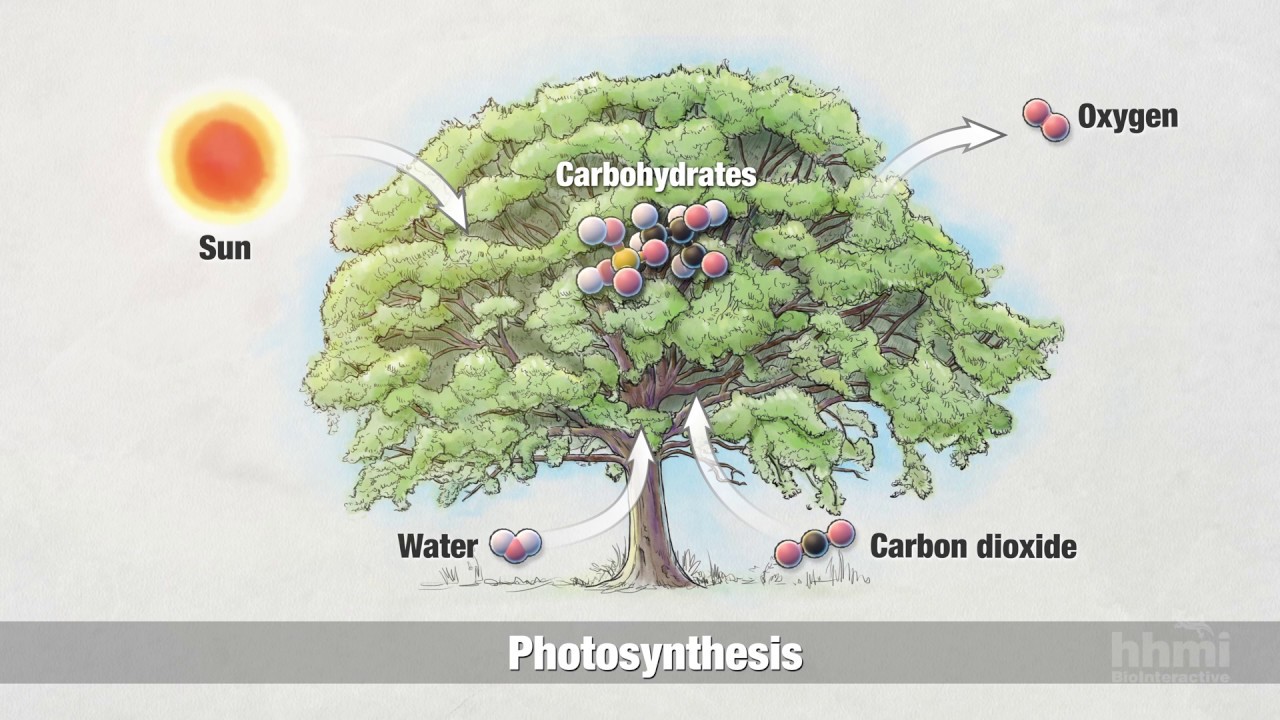

Photosynthesis: Part 2: Chemical Process | HHMI BioInteractive Video

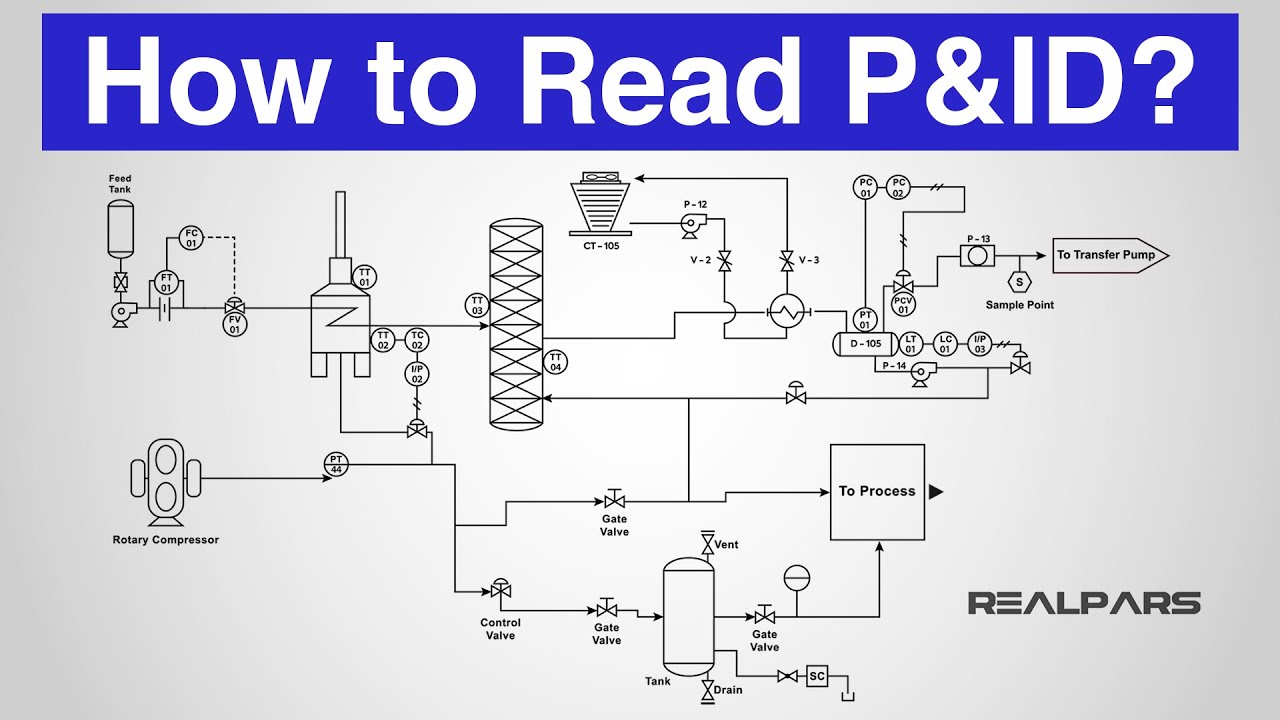

How to Read a P&ID? (Piping & Instrumentation Diagram)

5.0 / 5 (0 votes)