Combustion Chambers Part 1 - Aircraft Gas Turbine Engines #08

Summary

TLDRThe script delves into the intricacies of combustion chamber design in gas turbine engines, emphasizing the need for efficient fuel use and minimal atmospheric pollution. It outlines the importance of maintaining a maximum gas temperature of 1700 degrees Celsius to prevent turbine damage. The text explains how primary, secondary, and tertiary airflows interact to ensure stable combustion and temperature control, highlighting various cooling methods like ceramic tiles and transpiration cooling. It also touches on the historical development of combustion chambers from Sir Frank Whittle's design to modern systems like the Rolls-Royce Dart.

Takeaways

- 🔥 The combustion chamber is crucial for containing the mixture of air and fuel to generate heat at a constant pressure for the turbine.

- 🌟 Advancements in combustion chamber design aim to improve fuel efficiency and reduce atmospheric pollution.

- 🚫 There's a strict limit to the gas temperature exiting the combustion chamber, determined by the materials used in engine components.

- 🔧 Modern materials can withstand temperatures up to 1700 degrees Celsius, which is the limit before potential engine damage occurs.

- 🌡️ The air temperature can be increased by 1150 degrees Celsius through fuel combustion, starting from the compressed air's 550 degrees Celsius.

- 💨 The combustion chamber must maintain stable and efficient combustion across various engine operating conditions.

- 🌀 The air velocity is reduced and pressure increased after the compressor to ensure flame sustainability.

- 🔄 The airflow is divided into primary, secondary, and tertiary air flows to manage combustion and temperature.

- 🔥 The primary zone, where combustion occurs, is maintained by a specific air-fuel mixture and airflow design to prevent flameout.

- 🛠️ Different cooling methods, such as ceramic coating and transpiration cooling, are used to prevent overheating in combustion chambers.

Q & A

What is the primary function of a combustion chamber in a gas turbine engine?

-The combustion chamber's primary function is to contain the burning mixture of air and fuel to generate maximum heat release at a substantially constant pressure, ensuring the turbine receives a uniformly expanded heated and accelerated stream of gas.

Why is efficient combustion important in gas turbine engines?

-Efficient combustion is crucial due to the rise in fuel costs and the increasing awareness of the aviation industry and the public about the dangers of atmospheric pollution from exhaust smoke.

What is the maximum temperature limit for the gas exiting the combustion chamber, and why is this limit important?

-The maximum temperature limit for the gas exiting the combustion chamber is 1700 degrees Celsius. This limit is important because exceeding it can cause distortion of turbine blades and potentially lead to catastrophic disintegration of the turbine.

How does the temperature of the air leaving the high-pressure compressor affect the combustion process?

-The air leaving the high-pressure compressor may already be heated to around 550 degrees Celsius. Sufficient fuel can be added to raise the temperature of the gas exiting the combustion chamber by a further 1150 degrees Celsius, without exceeding the 1700 degrees Celsius limit.

What is the purpose of the divergent duct before the combustion chamber, and how does it affect the airflow?

-The divergent duct before the combustion chamber is used to slow down the airflow and increase its pressure. This is necessary to ensure that the flame can be sustained within the combustion chamber.

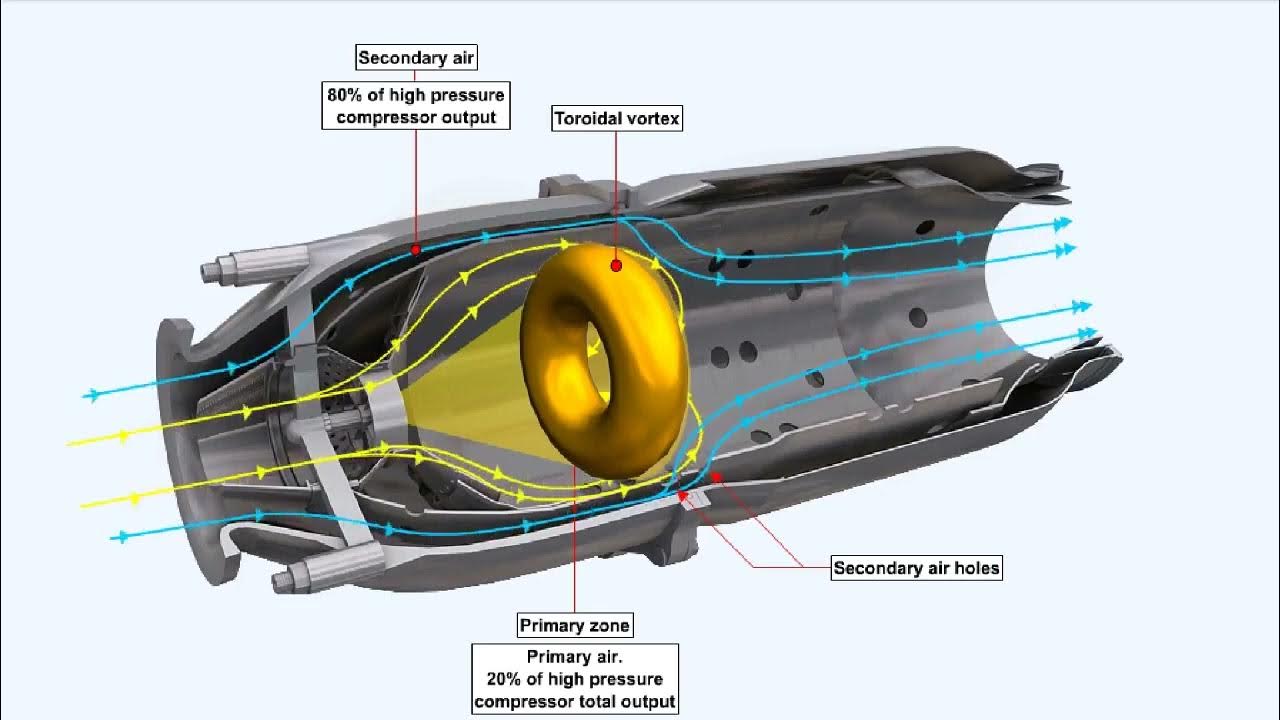

What are the three types of airflows from the high-pressure compressor into the combustion chamber, and what is their role?

-The three types of airflows are primary, secondary, and tertiary air. Primary air is mixed with fuel for combustion, secondary air forms a toroidal vortex to stabilize the flame, and tertiary air cools the air casing and the gas exiting the chamber.

How does the primary zone within the combustion chamber contribute to stable combustion?

-The primary zone is a region of lower velocity recirculation positioned immediately downstream of the fuel spray nozzle, where stable combustion is achieved by mixing primary air with fuel at a ratio of approximately 15 to 1 by weight.

What is the role of the secondary air in the combustion process?

-Secondary air reacts with the primary air flowing through the swirl vanes to form a toroidal vortex, which stabilizes and anchors the flame, preventing it from being moved away from the fuel nozzle area.

How does tertiary air help in managing the temperature within the combustion chamber?

-Tertiary air is used to cool both the air casing and the gas exiting the chamber. It is progressively introduced into the flame tube through corrugated joints and dilution air holes, helping to maintain a safe temperature for the engine components.

What are some methods used to prevent combustion chambers from overheating?

-Methods to prevent overheating include using ceramic coated tiles with cooling air passing through them, and transpiration cooling where a film of air flows between laminations forming the flame wall and then exits to form an insulating film within the flame tube.

What is the purpose of the interconnector in a multiple combustion chamber system?

-The interconnector in a multiple combustion chamber system allows the transfer of burning gases between chambers, ensuring that all chambers ignite sequentially and maintain equal pressure once all are burning.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)