Il ciclo di cottura della ceramica oggi iniziamo alle 17:30

Summary

TLDRIn this informative video, the instructor provides valuable insights into firing ceramic pieces in an electric kiln. She emphasizes the importance of understanding temperature curves, as they significantly impact the outcome. Variables such as kiln size, load, piece thickness, and insulation affect the ideal curve. The instructor guides viewers through the chemical and physical transformations occurring at different temperature ranges, stressing the need for a slow, controlled rise until reaching the desired peak. She also offers practical tips on kiln safety, loading, and troubleshooting. The video aims to demystify the firing process, empowering potters to achieve successful results.

Takeaways

- 😊 Make sure your pottery pieces are completely dry before placing them in the kiln to avoid issues during firing.

- ⚡ It's advisable to have an electrician check the electrical setup before installing a new kiln to ensure safety and compatibility.

- ⏲️ Different kilns and pottery piece sizes require different firing temperature curves - there's no one-size-fits-all approach.

- 🔥 The firing process involves several chemical transformations at different temperature ranges, which is why a slow and gradual temperature increase is crucial, especially up to 800-900°C (1472-1652°F).

- ⏱️ After reaching the desired peak temperature, a 20-minute hold is recommended before starting the cooling process.

- ⛔ Never force cool the kiln by opening it at high temperatures, as this can damage the heating elements and pottery pieces.

- 📏 Thicker pottery pieces require a slower initial heating rate to prevent cracking or explosions.

- 💰 Kiln prices can vary significantly depending on size, with some costing as low as $1,500 and others as high as $10,000.

- 🌡️ Different clay bodies have different maximum firing temperatures, so make sure your kiln can reach the required temperature for your chosen clay.

- 📖 Always follow the instructions provided by your kiln manufacturer, including running an initial empty firing to prepare the kiln for use.

Q & A

What are the important factors to consider when setting the temperature curve for a kiln?

-The temperature curve for a kiln depends on various factors such as the kiln size, the thickness of the kiln walls, the number and placement of heating elements, the size and thickness of the pieces being fired, and the type of clay being used. These factors affect how quickly the kiln can heat up and cool down.

Why is it important to have the pieces completely dry before firing?

-It is crucial to have the pieces completely dry before firing because any remaining moisture can cause the pieces to explode or crack during the firing process. The kiln does not like moist pieces, and the evaporation phase needs to be done very slowly.

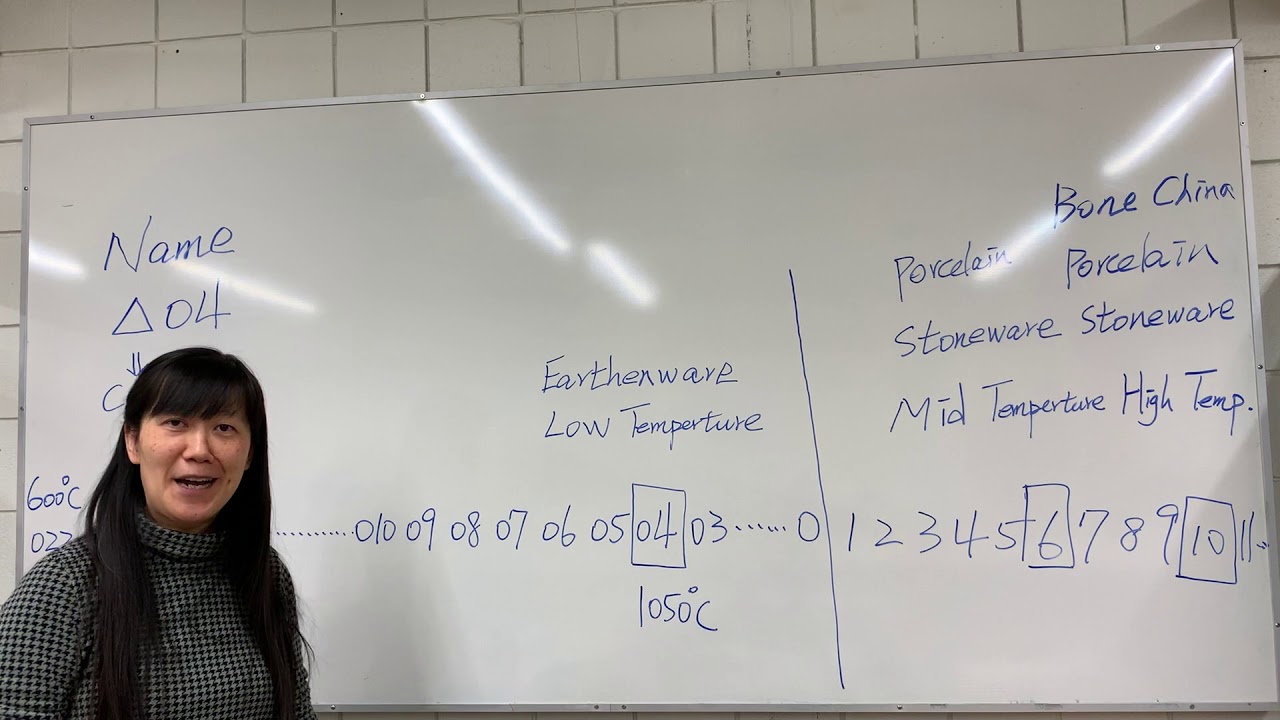

What happens during the different temperature ranges in a typical firing cycle?

-Around 100-200°C, the hygroscopic water is released from the clay. Between 300-600°C, organic substances in the clay start burning off. Around 573°C, the quartz in the clay undergoes a physical transformation, causing the pieces to shrink. Between 800-1000°C, most transformations are complete, and the temperature can be increased more rapidly. A short holding period at the maximum temperature is usually done before cooling.

Why is it important to cool the kiln slowly?

-Cooling the kiln too quickly can cause the pieces to crack or become damaged. The cooling phase should be done slowly and naturally, without forcing it by opening the kiln door while it is still hot. Opening the kiln too early can damage the heating elements.

What precautions should be taken when setting up a new kiln?

-When setting up a new kiln, it is important to have it checked by an electrician to ensure the electrical connection is suitable for the kiln's power requirements. The kiln should also be placed in a well-ventilated area, away from flammable materials, and not in an enclosed space where fumes can accumulate.

How can the temperature curve be adjusted based on the firing results?

-If the firing results show issues, such as pieces cracking or not reaching the desired maturity, the temperature curve can be adjusted accordingly. For example, the initial heating rate can be slowed down for thicker pieces, or the final heating rate can be increased for a more vitrified surface.

What is the importance of following the manufacturer's instructions for a new kiln?

-Following the manufacturer's instructions for a new kiln is crucial. These instructions often include information on setting up the kiln, conducting initial test firings, and recommended temperature curves for different types of clay and firing processes. Following these instructions can help ensure the longevity and proper functioning of the kiln.

How can the kiln load affect the temperature curve?

-A heavily loaded kiln will require a slower heating rate, especially in the initial stages, to allow the heat to penetrate evenly throughout the pieces. If the kiln is too tightly packed, the pieces in the center may not receive sufficient heat, leading to underfired or unevenly fired pieces.

What safety precautions should be taken when operating a kiln?

-When operating a kiln, it is important to ensure adequate ventilation to expel fumes, maintain a safe distance from the kiln during firing, and avoid opening the kiln door at high temperatures. Proper safety equipment, such as heat-resistant gloves and goggles, should be used when handling hot pieces.

How can the type of glaze or surface treatment affect the firing process?

-Different glazes and surface treatments may require specific firing temperatures and cooling rates. For example, some glazes may need a slower cooling rate to prevent crazing or shivering, while others may require a specific temperature range for proper maturation.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Rifinitura a Secco - Scuola Ceramica Online

Da argilla a ceramica - La trasformazione in cottura

23.13 Name clay and tools, and Information for clay types and temperatures

Smaltatura ceramica ad immersione, come smaltare la terracotta e la ceramica

Primitive Technology: Mud Bricks

Panoramica delle tecniche di decorazione principali in ceramica

5.0 / 5 (0 votes)