Da argilla a ceramica - La trasformazione in cottura

Summary

TLDRIn this informative video, the host provides a comprehensive guide on the ceramic firing process, from the initial malleable clay stage to the final glazed and fired ceramic piece. The host explains the different stages, including the leather-hard, bone-dry, and bisque firing steps, and emphasizes the importance of proper drying and firing temperatures. The video also addresses common questions and concerns, such as firing ceramics in a home oven, the compatibility of glazes and clay bodies, and techniques like single firing. Overall, the video offers valuable insights for both beginners and experienced ceramists, shedding light on the intricacies of the ceramic firing journey.

Takeaways

- 🔥 Home ovens cannot be used for firing ceramics as they lack the required high temperatures (around 1000°C) and prolonged firing durations (8-12 hours).

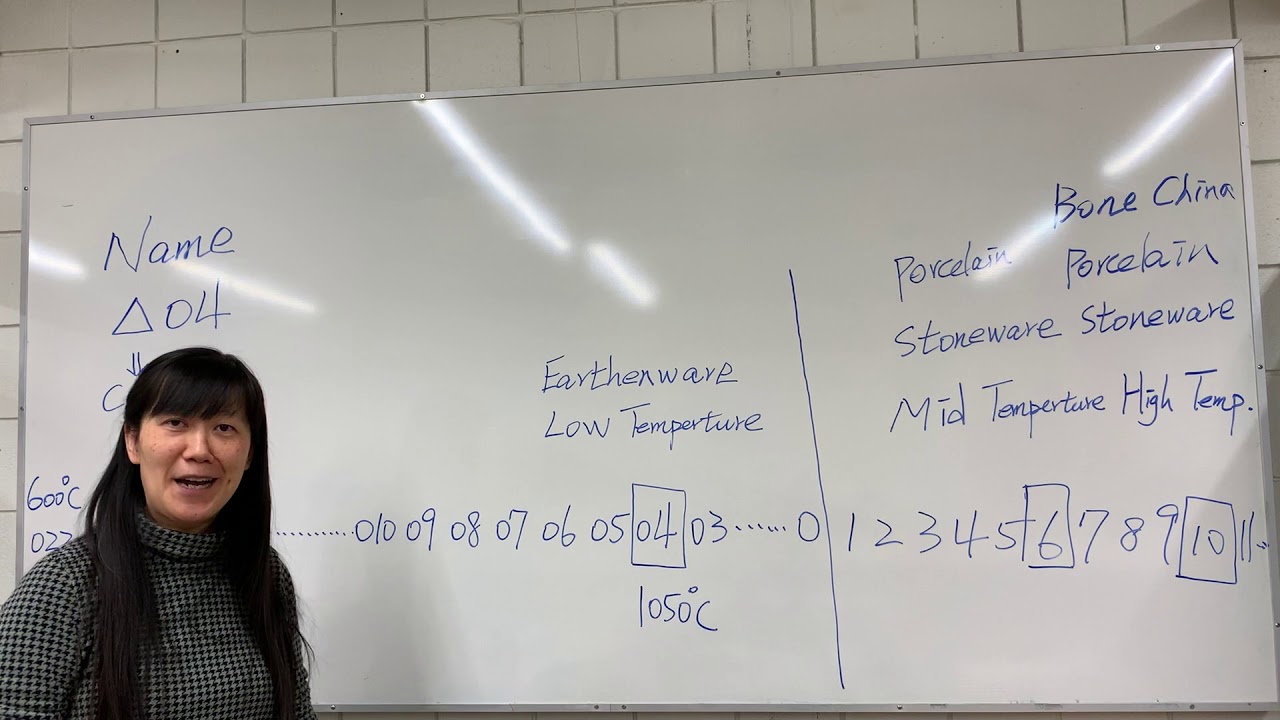

- 📐 The ceramic firing process involves several stages: soft clay → leather-hard → bone-dry → bisque firing (900-1000°C) → applying glaze → glaze firing at final temperature.

- ⚠️ Pieces must be completely dry before bisque firing, as any moisture can cause dangerous explosions inside the kiln.

- 💎 The bisque firing creates a porous, absorbent ceramic body ideal for applying glaze, which is essentially a glass powder suspension in water.

- 🌡️ The glaze firing temperature depends on the clay body and glaze composition, typically ranging from 980°C to 1200°C or higher.

- 🔄 Single firing (monocottura) is possible but may not yield the same results as the traditional two-firing process (bisque and glaze firing).

- 🧱 For low-temperature firings, the glaze temperature can be equal to, lower than, or higher than the bisque temperature, as long as they are compatible.

- 🍽️ High-temperature clays (like stoneware and porcelain) require the glaze and clay body to be fired together at the same final temperature.

- 🛡️ Applying a refractory coating (e.g., kaolin and alumina mixture) on kiln shelves prevents glazes from sticking to the shelves during firing.

- 📚 Consulting the manufacturer's instructions on the clay body packaging is crucial for determining the appropriate firing temperature range.

Q & A

Why can't ceramics be fired in a home oven?

-Home ovens cannot reach the high temperatures required for firing ceramics, which is around 1000 degrees Celsius, and lack the necessary power and resistance for a complete firing process.

What is the initial state of clay before it is modeled and why is it important?

-The initial state of clay must be soft and pliable to be easily modeled into various shapes. This state is crucial for the creative process, allowing for flexibility in design before firing.

What is leather hard clay and how is it useful in the ceramic process?

-Leather hard clay refers to a semi-dry state where the clay is firm enough to handle but still moist enough to be carved or joined with other pieces. This state is ideal for making detailed adjustments or attachments.

How does the firing process transform clay into ceramic?

-The firing process involves heating the clay in a special kiln to high temperatures, causing chemical and physical changes that solidify the clay into a durable ceramic material.

What is the difference between bisque firing and glaze firing?

-Bisque firing is the first high-temperature firing that turns soft clay into hard, porous ceramic (bisque). Glaze firing is the second firing after applying glaze, which melts to form a glassy surface on the bisque.

Why is it important for a piece of ceramic to be completely dry before firing?

-If the ceramic piece contains moisture when fired, it can lead to explosions in the kiln as the water turns to steam and expands, potentially damaging the piece and the kiln.

Can the temperature range on clay packaging indicate the suitable firing temperature for both bisque and glaze firings?

-The temperature range typically refers to the optimal temperature for glaze firing, ensuring the clay matures properly and the glaze adheres correctly, resulting in a durable final product.

What is the purpose of applying glaze to ceramics?

-Glaze serves to make the ceramic piece impermeable, creating a glassy, often colorful surface that is also food-safe and resistant to staining and water absorption.

Is it possible to fire ceramics in a single firing process?

-Yes, single firing, or once-firing, is possible and involves applying glaze to unfired, dry clay and firing it all at once, but the results can differ from the traditional bisque then glaze firing process.

What precautions should be taken when firing glazed ceramics in the kiln?

-It's important to ensure that the glazes used are compatible with the firing temperature and that pieces do not touch each other to prevent them from sticking together when the glaze melts.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Ceramic tiles manufacturing process by Ceratec - How it's made?

Amazing Modern Ceramic Tile Manufacturing Process With Advance Technology And Creative Workers

INTERESSANTE Como é feito TELHA

23.13 Name clay and tools, and Information for clay types and temperatures

Barbottina: che cos'è e come si realizza?

Il ciclo di cottura della ceramica oggi iniziamo alle 17:30

5.0 / 5 (0 votes)