#001.Tips Belajar Supaya Cepat Menguasai Las listrik(SMAW), Mulai dari Latihan ini

Summary

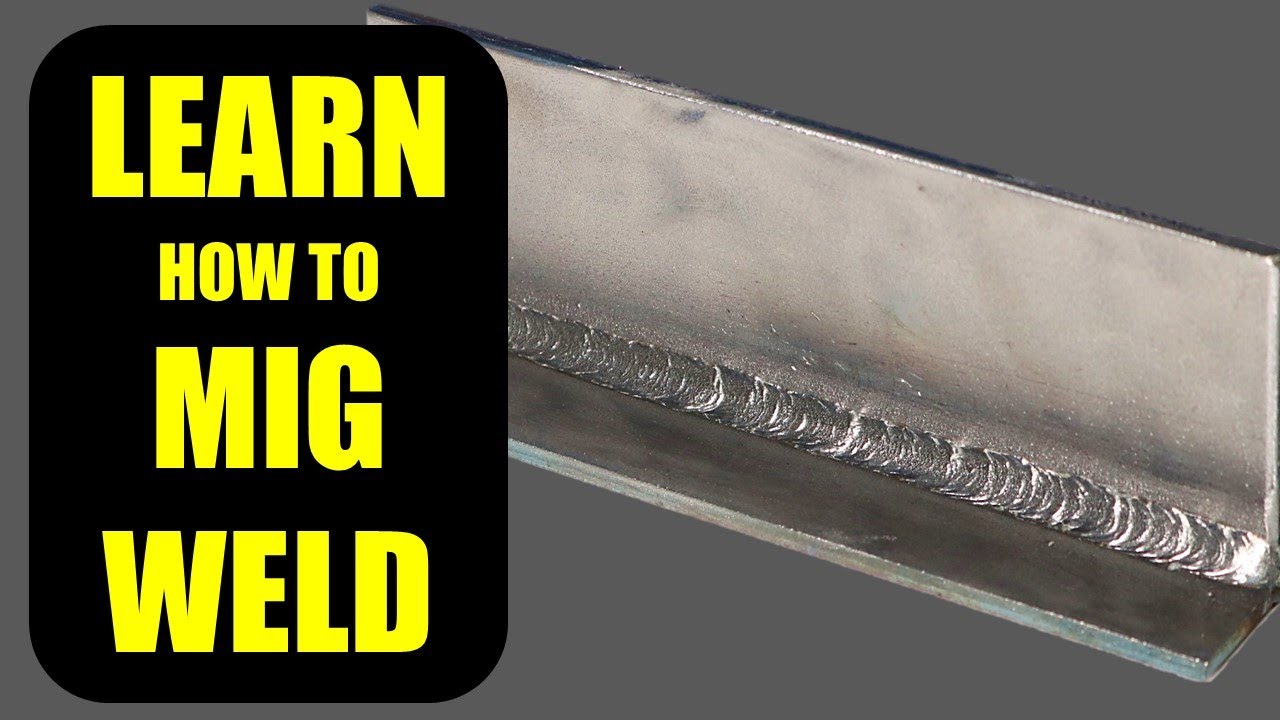

TLDRIn this video, viewers are introduced to the basics of mastering electric welding techniques. The host shares valuable tips on how to clean the workpiece to prevent welding defects, followed by step-by-step instructions on electrode handling and maintaining hand stability during welding. The video emphasizes the importance of controlled, steady hand movements and correct electrode temperatures for producing quality welds. The presenter encourages learners to practice these techniques, maintain proper hand stability, and select the best welding methods that suit them for improved results.

Takeaways

- 😀 Before starting welding, ensure the workpiece surface is clean from oil, water, sand, and rust to avoid defects in the weld.

- 😀 Mark the workpiece or use a grinder to create a guide for accurate welding placement.

- 😀 Ensure the electrode temperature is around 500°C before beginning the welding process.

- 😀 Maintain a steady hand while welding to prevent unstable movements that can lead to poor weld quality.

- 😀 During welding, avoid rushing and control the speed of your hand movements to ensure a smooth and stable weld.

- 😀 Any inconsistencies in the weld, such as burns or impurities, indicate that the welding process might need adjustments.

- 😀 The hand must remain stable to achieve consistent welds, avoiding excessive shaking or jerking movements.

- 😀 Ensure that the welding angle remains appropriate for the best results, aligning with the metal's thickness and the electrode's position.

- 😀 Try different welding motions, such as oscillating or steady movements, to determine the best technique for your comfort and the material.

- 😀 Always aim to improve your hand stability with practice, which will result in better welding outcomes over time.

- 😀 Regularly check the equipment and the workpiece's surface condition to ensure optimal welding conditions.

Q & A

What is the focus of the video tutorial?

-The video tutorial focuses on teaching how to quickly master electric welding techniques, with particular emphasis on preparing the workpiece, controlling the electrode, and achieving stable welding results.

Why is it important to clean the workpiece before welding?

-Cleaning the workpiece is crucial to remove contaminants such as oil, water, dust, and rust. This ensures that the welding process is smooth and prevents defects in the weld.

What should be done after cleaning the workpiece?

-After cleaning, the workpiece should be marked or grinded to create a guide for the welding process, ensuring accurate placement of the weld.

What temperature should the electrode reach before starting the welding process?

-The electrode should be heated to around 500°C before beginning the welding process to ensure proper functioning and stability.

How does the movement of the hand affect the welding result?

-The movement of the hand should be stable and controlled to avoid shaky or rushed actions. Unstable movements can result in poor-quality welds.

What is the significance of avoiding excessive hand shaking during welding?

-Avoiding excessive hand shaking helps maintain consistent welding quality and prevents defects such as uneven welding beads or porosity in the weld.

How should the hand be positioned during welding?

-The hand should be kept stable and steady, following the welding path precisely. Stability is key to producing a smooth and clean weld.

What should a welder focus on when practicing welding over time?

-A welder should focus on improving hand stability and control as they practice, ensuring their movements become more consistent and precise with experience.

Is it necessary to follow the exact same swing method for every weld?

-While the basic swing method should be consistent, the exact technique may vary depending on the specific project. The goal is to find a method that is comfortable and effective for the welder.

What final advice does the speaker give to the viewers?

-The speaker encourages viewers to keep practicing to improve their welding skills and reminds them to subscribe and like the video if they found it helpful.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Mig Welding Basics part 5 - Practice

Telecurso 2000 Processos de Fabricação 14 O arco elétrico entra em ação

Membedah Procedure Text " HOW TO USE PHOTOSHOP " | DIJAMIN KALIAN BISA PROCEDURE TEXT & PHOTOSHOP

MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips, Tricks & Techniques!!

TDT full course part3

How to MIG Weld for Beginners: MIG Welding Basics

5.0 / 5 (0 votes)