What is Modbus and How does it Work?

Summary

TLDRThe video script introduces the Modbus communication protocol, a widely used standard in process automation and SCADA systems. Modbus, developed by Modicon (now part of Schneider Electric) in 1979, facilitates communication between industrial electronic devices. It operates on various physical media, including RS-232, RS-485, and Ethernet, and supports both point-to-point and multidrop networks. The protocol uses a master/slave architecture where the master initiates transactions and slaves respond with requested data. Modbus messages are structured with error checking to ensure data integrity. The video also highlights the importance of understanding Modbus for professionals in the field, emphasizing its role in integrating devices from different manufacturers and its demand in the industry.

Takeaways

- 📈 **Open Protocols**: Open protocols like Modbus allow for device interoperability, enabling manufacturers to integrate their products easily into the market, providing users with a wide range of device choices.

- 🤝 **Community Support**: Open protocols are often backed by a diverse group including corporations, user groups, professional societies, and governments, offering robust community support.

- 🚀 **Modbus Protocol**: Modbus is a widely used communication protocol in process automation and SCADA systems, essential for electrical technicians and engineers to understand and implement.

- 🔌 **Modbus Versions**: Several versions of Modbus exist, including RTU, ASCII, TCP, and Plus, each designed for different types of communication media and network architectures.

- 💬 **Communication Architecture**: Modbus operates on a master/slave architecture, with the master device initiating transactions and the slave devices responding with the requested data.

- 🌐 **Physical Media**: Modbus can communicate over various physical media such as RS-232, RS-485, RS-422, and Ethernet, with the choice depending on the specific application and distance requirements.

- 🔄 **RS-485 Advantages**: RS-485 is preferred for Modbus implementations due to its support for longer distances, higher speeds, and the ability to connect multiple devices on a single network.

- 📨 **Modbus Messaging**: Modbus messages are sent in plain text over dedicated networks or embedded within Ethernet packets when co-existing with other protocols on TCP/IP networks.

- 📡 **Point-to-Point and Multidrop**: Modbus supports both point-to-point and multidrop networks, allowing for flexible communication setups.

- 🔑 **Master/Slave Communication**: In Modbus, only the master can initiate transactions, while slaves respond to queries and do not initiate communication unless addressed directly.

- 🛡️ **Error Checking**: Modbus includes error checking mechanisms to ensure the integrity of the data being transmitted between devices, with the master verifying the accuracy of the received information.

Q & A

What is the significance of using open protocols in device to device communication?

-Open protocols allow for greater interoperability between devices from different manufacturers. They are published specifications that can be used freely or by license, enabling a wide range of devices or systems to be utilized for specific applications. This provides users with more choices and the ability to stay current and add capabilities in the future.

What are the advantages of using open protocols in industrial automation?

-The advantages include support from multiple manufacturers, software vendors, and install/service organizations, active community groups for support, and the ability to integrate devices from different manufacturers, making professionals more valuable and marketable in the industry.

What is the Modbus communication protocol?

-Modbus is a communication protocol published by Modicon in 1979 for use with its programmable logic controllers (PLCs). It provides a common language for devices and equipment to communicate with one another and is used extensively in process automation and SCADA systems.

What types of Modbus communication are commonly used in the industry?

-The most common types of Modbus communication used in the industry are Modbus RTU, Modbus ASCII, Modbus TCP, and Modbus Plus. These versions cater to different needs and physical media such as serial ports and Ethernet.

How does Modbus enable communication between devices?

-Modbus enables devices to communicate by allowing them to send and receive messages. For example, devices measuring temperature and humidity can communicate their results to a supervisory computer or PLC using Modbus.

What is the role of the Modbus Organization?

-The Modbus Organization is an association of users and suppliers of Modbus-compliant devices. It manages the development and updates of Modbus protocols.

What is the architecture of Modbus communication interface?

-The Modbus communication interface is based on a master/slave architecture. Communication between Modbus nodes is achieved with send request and read response type messages.

How does Modbus communication work over different physical media?

-Modbus communicates over several types of physical media such as serial RS-232, RS-485, RS-422, and over Ethernet. The physical media is selected at the time of purchasing the devices. Modbus messages are sent in plain form over simple interfaces like RS-485 and RS-232, while over Ethernet, they are embedded in Ethernet packets.

What is the main message structure of Modbus?

-The main Modbus message structure is peer-to-peer. It can function on both point-to-point and multidrop networks, using a master/slave technique where only the master can initiate transactions.

How does a Modbus master communicate with slaves?

-A Modbus master communicates with slaves by addressing individual slaves or initiating a broadcast message to all slaves. The master's query consists of a slave address, a function code with a read or write data command, and an error checking field.

What happens if a Modbus slave encounters an error or is unable to perform a requested action?

-If a slave encounters an error or is unable to perform the requested action, it will return an exception message as its response. The error check field in the slave's message frame allows the master to confirm the validity of the message contents.

What is the next step for someone interested in learning more about Modbus and PLC programming?

-For further learning on Modbus and PLC programming, one can visit realpars.com, which offers easy-to-understand formats to enhance career prospects in these fields.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

IoT Protocols | MQTT | CoAP | OPC-UA | Modbus | LoRA | Industrial Automation IIoT

SCADA Hacking | Operational Technology (OT) Attacks

RS-232 Explained: Working Principle, Pinout, Cables & Applications

What Is...I2C?

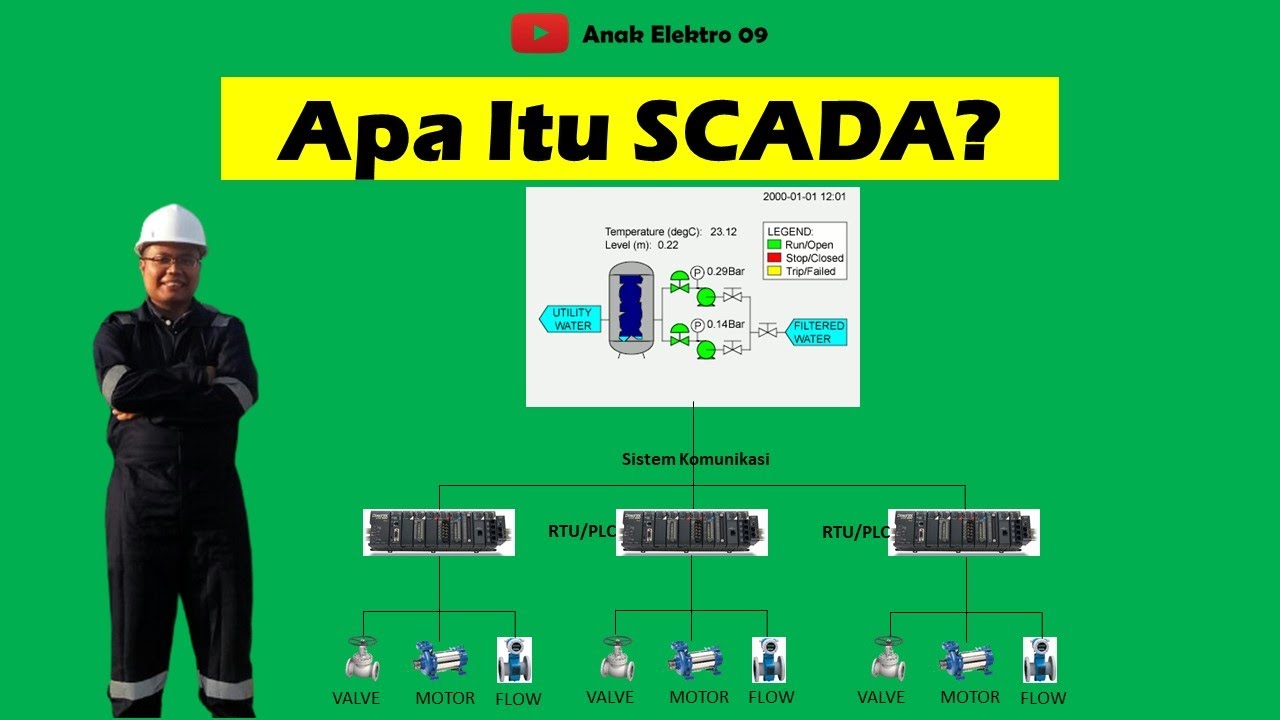

Pengenalan SCADA (Supervisory Control And Data Acquisition)

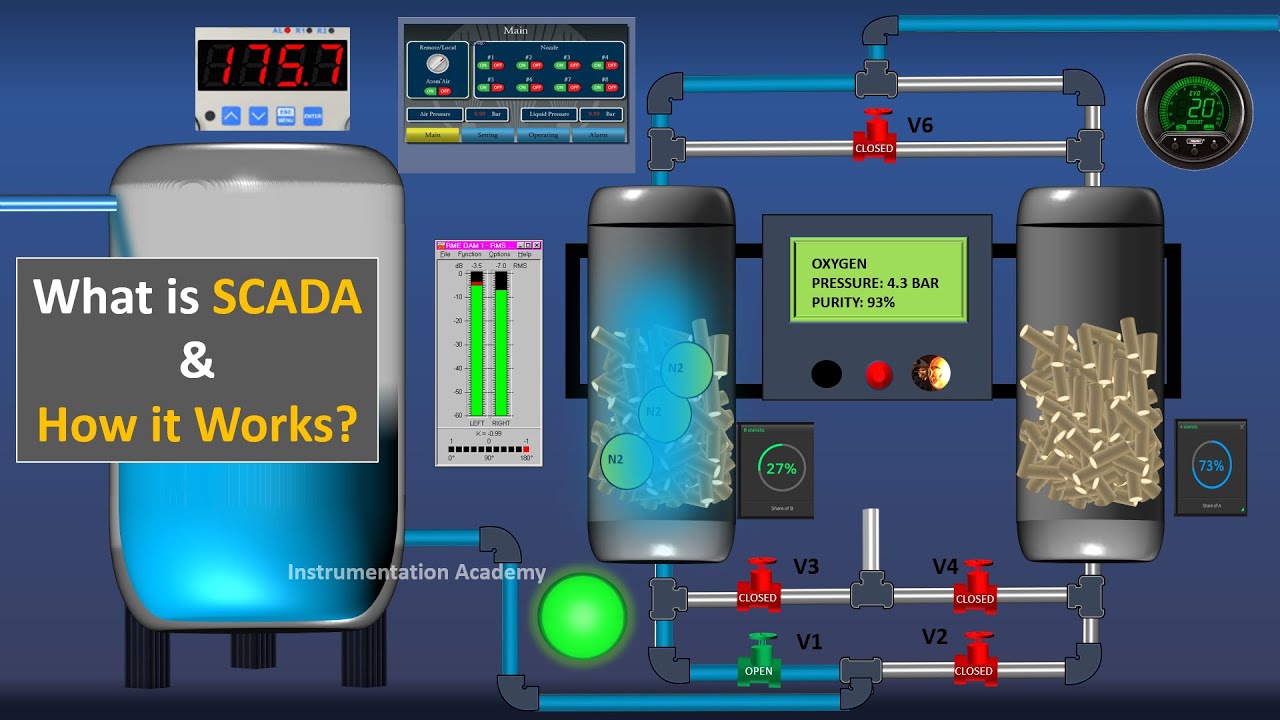

What is SCADA, How SCADA Works, Components, Architecture & Applications. SCADA Tutorial

5.0 / 5 (0 votes)