Boiler Parts and Their Functions

Summary

TLDRThis comprehensive overview of a D-type boiler explains its intricate design and functioning, including the roles of the upper and lower drums, pipes, and various components like economizers and air preheaters. It details the flow of water and steam, energy efficiency measures, and the critical importance of proper combustion. The transcript also highlights safety features, including multiple safety valves, and describes the turbine's energy conversion processes. By understanding these elements, viewers gain insights into optimizing steam plant efficiency and the challenges involved in boiler operation and maintenance.

Takeaways

- 🔧 The D-type boiler consists of an upper steam-water drum and a lower water drum connected by hundreds of tubes and pipes.

- 🔥 Water circulates through pipes arranged in the furnace, heated by flames from oil burners, allowing for a steam-water mixture to flow to the upper drum.

- 💨 The steam-water mixture travels through the boiler at a velocity of 0.3 to 1 meters per second, resulting in approximately 0.25% water content in the saturated steam.

- 🌡️ Primary steam enters the evaporating coil in the secondary steam drum, where it is condensed and heated above boiling temperature in the superheater.

- ⚙️ Exhaust gas boilers are installed to recover energy lost in exhaust gases, utilizing dampers to control heat flow to evaporating coils.

- 💧 The economizer preheats feed water before it enters the steam-water drum, increasing energy content and improving thermal efficiency.

- 🚿 De-superheating is achieved by injecting water into the steam flow to reduce temperature while maintaining high pressure.

- 🌬️ Air preheaters utilize counterflow principles to recover heat from exhaust gases, and their efficiency is essential to prevent sulfuric acid formation.

- 🔄 Safety valves are critical for preventing excessive pressure in the boiler, with spring-loaded and full stroke types ensuring proper operation.

- 💡 Turbines convert steam energy into mechanical work, using convergent and convergent-divergent nozzles to achieve high steam velocities for efficiency.

Q & A

What are the major components of a D-type boiler?

-The major components of a D-type boiler include the upper drum (steam water drum), lower drum (water drum), numerous tubes and pipes, economizer, superheater, air preheater, and various pumps and safety valves.

How does the water circulate within the D-type boiler?

-Water circulates inside the pipes arranged as risers in the furnace. The heated water in the risers becomes lighter than the cooler water, causing it to flow upwards to the upper drum, while the heavier water flows back down to the lower drum through downcomers.

What role does the economizer play in the boiler system?

-The economizer heats the feed water before it enters the steam water drum, increasing its temperature and enhancing the thermal efficiency of the steam plant by utilizing heat from exhaust gases.

What is the purpose of the superheater in a boiler?

-The superheater heats the steam above its boiling temperature, increasing its energy content. This superheated steam is crucial for various applications, ensuring efficient energy transfer and operation.

Why is it important to maintain a sufficient flow of steam through the superheater?

-Maintaining a sufficient flow of steam through the superheater is essential to prevent overheating and potential damage, ensuring efficient operation and optimal energy transfer.

What issues can arise from incomplete combustion of fuel oil in the boiler?

-Incomplete combustion can lead to soot and other deposits forming in the furnace and exhaust uptake, which reduces heat transfer efficiency and necessitates more frequent cleaning through soot blowing.

How do safety valves function in a boiler system?

-Safety valves prevent steam pressure from exceeding safe levels. They open when pressure rises above a preset limit, allowing steam to escape and maintaining pressure within safe operating parameters.

What are the different types of turbines mentioned in the script?

-The script mentions several types of turbines, including feed water turbines, cargo pump turbines, and turbine-driven generators. They can be categorized as back pressure or vacuum condenser types.

How does the de-aerator contribute to the boiler's efficiency?

-The de-aerator serves as an expansion tank for condensate, removing air and non-condensable gases from the feed water, which prevents issues such as steam flashing and cavitation, thus optimizing boiler efficiency.

What maintenance practices are necessary for maintaining boiler efficiency?

-Regular soot blowing, inspection of burners for proper atomization, and checking for deposits in air preheaters and economizers are critical maintenance practices necessary to maintain boiler efficiency.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Boiler Water and Steam Cycles - Understand the working

BOILER PABRIK KELAPA SAWIT

How Fuel Oil Burners Work: Boilers and Their Operation - 1956 - CharlieDeanArchives

The Respiratory System CRASH COURSE

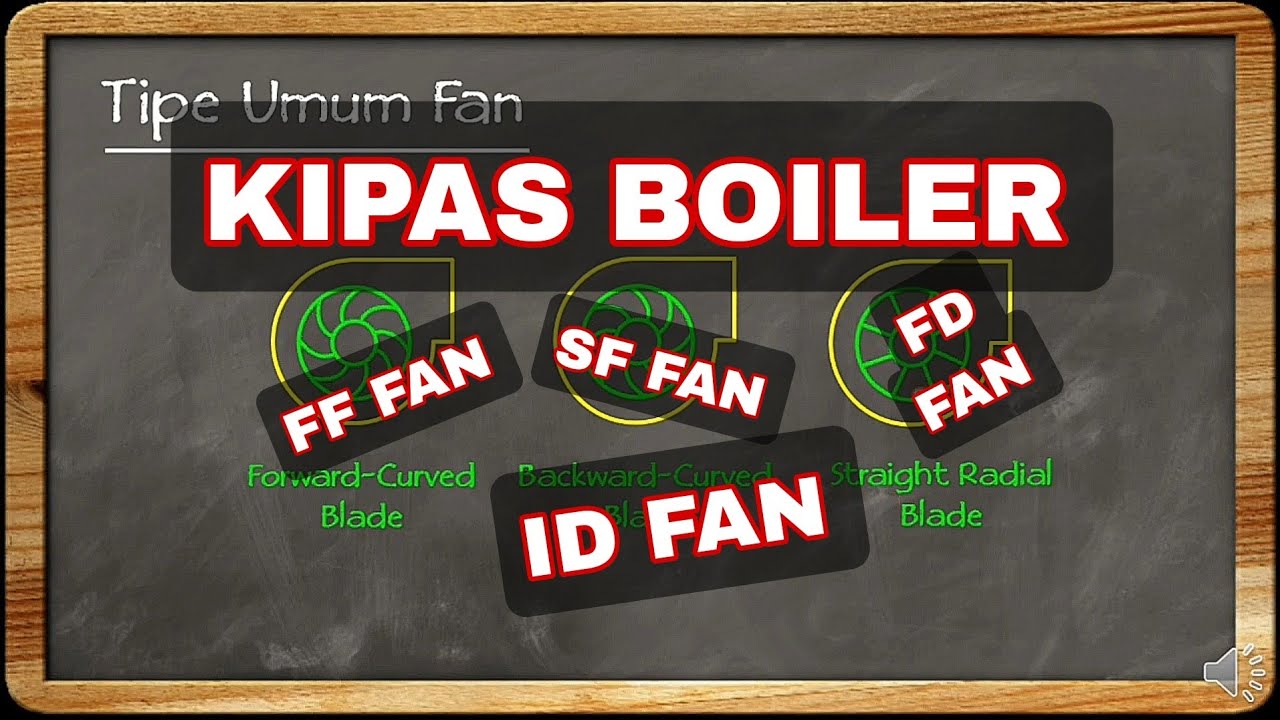

Boiler Fan #FAN #CENTRIFUGAL #BOILER #PABRIKSAWIT #OPERATOR #KIPASANGIN #PMKS #DRAFT #CONTROL #FIRE

Boiler Control Systems

5.0 / 5 (0 votes)