Andon&Loom

Summary

TLDRThe video explores the Toyota production system, emphasizing the importance of quality control at every stage of manufacturing. Workers use a cord to halt the production line if they encounter issues, fostering a culture of teamwork and accountability. The philosophy traces back to Toyota's origins in 1924, starting as a loom company founded by Sakichi Toyota, who innovated a machine that automatically stops when a thread breaks. This principle of stopping for quality remains integral to Toyota's operations, ensuring that only flawless products are passed down the line.

Takeaways

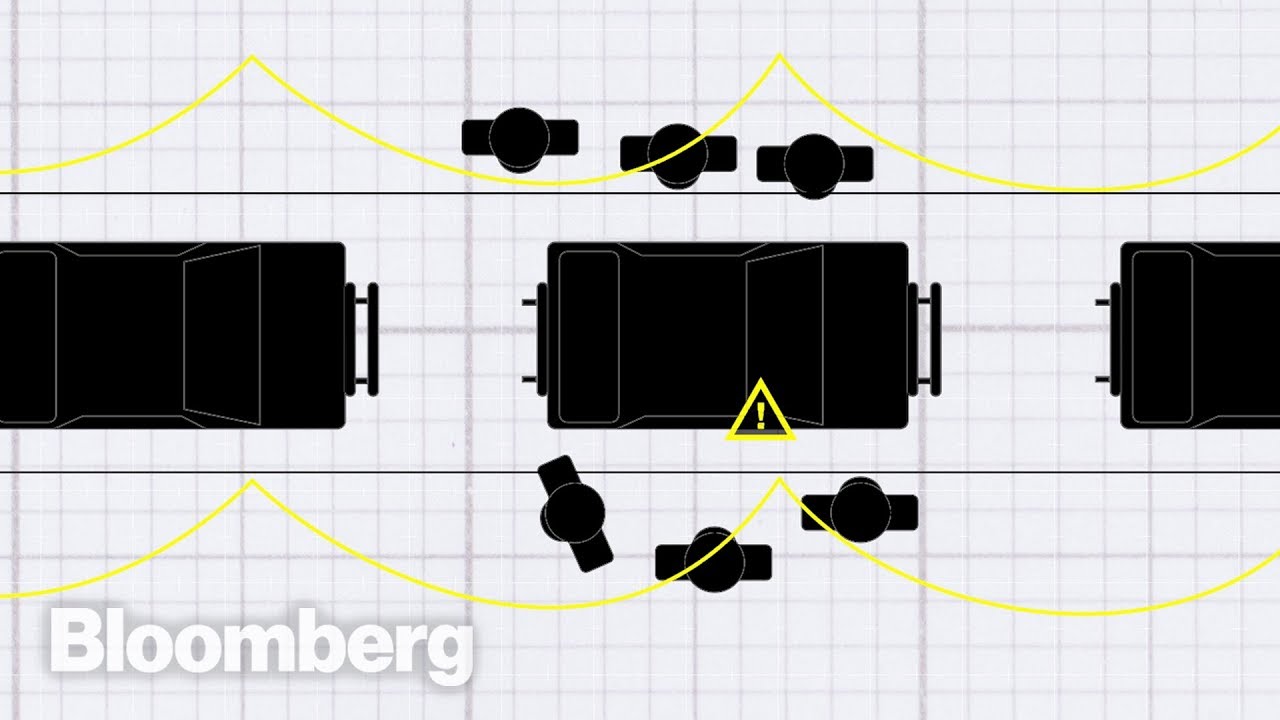

- 🔧 The white cord along the production line helps ensure quality control; if issues arise, workers can halt production.

- 🔔 An alarm sounds and a warning light activates if the installation process encounters problems.

- 🤝 Teamwork is essential; if a worker cannot resolve an issue, they can call for support from line leaders.

- 🚫 Sending substandard work down the production line is considered unacceptable; every employee plays a role in maintaining quality.

- ⚽ The production approach is likened to a sports mentality: 'one for all, all for one.'

- 🏭 The Toyota production system prioritizes high-quality output; production halts if work isn't perfect.

- 📜 Toyota's philosophy of quality control dates back to the company's founding in 1924.

- 🧵 Toyota originally started as a textile company, producing automatic looms before becoming a car manufacturer.

- 🔍 The automatic loom features a pin system that stops the machine when a thread breaks, ensuring quality.

- 🏆 This pin system reflects Toyota's longstanding commitment to quality and problem-solving in production.

Q & A

What is the purpose of the white cord along the production line?

-The white cord helps workers guarantee quality by allowing them to pull it if there is a problem, which triggers an alarm and a warning light.

What happens when a worker pulls the cord?

-When the cord is pulled, a line leader quickly comes to assist. If the issue cannot be resolved in a timely manner, the entire production line stops.

How does Toyota's production approach ensure quality?

-Every employee is responsible for the quality of their work, and substandard work is not allowed to leave their station. They can call for help if they cannot resolve an issue themselves.

What is the philosophy behind stopping the production line?

-Stopping the production line is not seen as a problem; it is viewed as a necessary step to maintain quality and ensure that only well-done work is passed on to the next team.

How is Toyota's production philosophy compared to sports?

-The production philosophy is likened to sports with the idea of 'one for all, all for one,' emphasizing teamwork and collaboration.

What significant historical milestone is mentioned about Toyota?

-Toyota started in 1924 as a spinning and weaving company, not initially as a car manufacturer.

What unique feature did Sakichi Toyota’s looms have?

-The looms included a pin system that automatically stopped the machine if a thread broke, preventing defects in the textile production process.

How does the automatic loom's stopping mechanism relate to the production line?

-The stopping mechanism of the loom, which halts the machine upon detecting a fault, mirrors the production line's philosophy where any fault leads to a stop until resolved.

What does the consistent application of Toyota's production philosophy signify?

-It signifies a longstanding commitment to quality that has been maintained for nearly 100 years, reflecting the company's core values and operational principles.

How does the production line philosophy impact employee mindset?

-The philosophy instills a sense of courage and accountability among employees, encouraging them to acknowledge mistakes and seek help to ensure high-quality outputs.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

How Toyota Maintains 99.9999% Quality | Toyota Quality Management System | Invensis Learning

Understanding Quality Assurance - GCSE Business Studies Revision - OCR, Edexcel, AQA - BizzWizard

Toyota Production Documentary Toyota Manufacturing Production and Assembly at Toyota Factory

MOMENT LANGKA!!! LIHAT LANGSUNG PRODUKSI TOYOTA YARIS CROSS DI PABRIKNYA!!! WAJIB TONTON! | GridOto

History of the Toyota Production System (TPS)

How Toyota Changed The Way We Make Things

5.0 / 5 (0 votes)