Modeling for 3D Printing

Summary

TLDRIn this video, Tyson provides a comprehensive guide to 3D printing from SketchUp, covering essential tips for preparing models, exporting STL files, and optimizing prints. He emphasizes creating solid objects, setting the correct units, scaling small geometry for accuracy, and matching wall thickness to nozzle size. Viewers learn about tolerances for interlocking parts, minimizing supports, and the difference between bevels and radii for better layer adhesion. Practical advice on file organization, slicer previewing, and managing print time makes this an invaluable resource for beginners and experienced users alike, offering insights to streamline the 3D printing process and achieve successful prints.

Takeaways

- 😀 Always export solid objects from SketchUp for 3D printing to avoid errors from missing faces or stray lines.

- 😀 Convert SketchUp units to millimeters before exporting STL files to ensure correct scale in slicing software.

- 😀 Scale up small models to fix geometry issues, then scale them back down for better print accuracy (Dave R method).

- 😀 Consider the printer's nozzle size (e.g., 0.4 mm, 0.6 mm, 0.8 mm) when designing walls and features for optimal print speed and detail.

- 😀 Allow tolerance between interlocking parts to accommodate printer variability and ensure smooth movement.

- 😀 Export individual pieces separately or arrange them on the ground plane to simplify slicing and printing setup.

- 😀 Minimize supports by orienting models strategically, reducing material use, print time, and cleanup effort.

- 😀 Use bevels or chamfers with consistent slopes instead of radii where possible to reduce overhang issues and improve filament bonding.

- 😀 Experimentation is key: different materials, nozzles, and settings will affect print results, so be patient and adjust as needed.

- 😀 Modern 3D printing has a low barrier to entry, offering reliable machines at affordable prices, but expect some trial and error.

- 😀 Preview your sliced models in software like Ultimaker Cura to understand how layers and infill will build up before printing.

- 😀 Larger nozzles can significantly reduce print time, but may reduce fine detail, so balance nozzle size with model requirements.

Q & A

Why is it important to send a solid object to the 3D printer?

-Solid objects ensure the printer can interpret the geometry correctly. Missing faces or extra edges can cause errors during printing, so making groups or components solid helps avoid these issues.

What unit should SketchUp models be exported in for most slicing software?

-Models should be exported in millimeters because most slicing software prefers millimeter units. Exporting in inches may lead to incorrect scaling or conversion issues.

What is the 'Dave R method' in SketchUp 3D printing?

-The Dave R method involves scaling a small object up by a known factor, performing modeling operations like bevels or follow-me, and then scaling it back down. This helps resolve small geometry gaps and improves print accuracy.

How does nozzle size affect 3D printing?

-Nozzle size determines both print speed and detail. Standard 0.4 mm nozzles provide a good balance of detail and speed, while larger nozzles (0.6–0.8 mm) print faster but with less precision. Wall thickness should be considered relative to the nozzle size.

Why should you model interlocking pieces with tolerances?

-3D prints are not perfectly precise, so adding slight gaps ensures movement, proper fit, and accounts for variability in the printing process, especially for friction-fit or sliding components.

What is the recommended way to export multiple parts from SketchUp?

-Export parts individually or arrange them on the ground plane before exporting. This prevents issues in the slicer and makes each part easier to print and manage.

Why should you minimize supports in 3D printing?

-Supports increase print time, material usage, and post-processing effort. Orienting parts to reduce overhangs minimizes the need for supports, resulting in cleaner prints and faster production.

How do bevels compare to radii in terms of 3D printing?

-Bevels create consistent slopes that are easier to print, while radii can create overhangs that may cause gaps in the print. Using bevels improves layer adhesion and reduces potential printing problems.

What is the basic workflow for preparing a SketchUp model for 3D printing?

-The workflow involves: creating solid geometry, checking units, scaling small objects if needed, considering nozzle size and tolerances, exporting parts individually, slicing in software with appropriate settings, and finally printing and iterating.

What should beginners expect when starting with 3D printing?

-Beginners should expect some frustration due to trial and error. Modern printers are reliable and affordable, but experimentation with models, supports, and print settings is essential for learning.

Why is scaling small objects beneficial in SketchUp before printing?

-Scaling up small objects helps resolve geometric issues like missing faces or gaps that SketchUp may not automatically fix. Once the modeling operations are complete, scaling back down ensures proper size while maintaining printable geometry.

How does wall thickness interact with nozzle size during printing?

-Wall thickness should ideally match a multiple of the nozzle diameter. For example, a 1 mm wall takes two passes with a 0.4 mm nozzle but only one pass with a 0.8 mm nozzle, affecting print speed and quality.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

How to Use a 3D Printer for Complete Beginners

Automate your Bambu Lab P1 & X1! Free & Easy

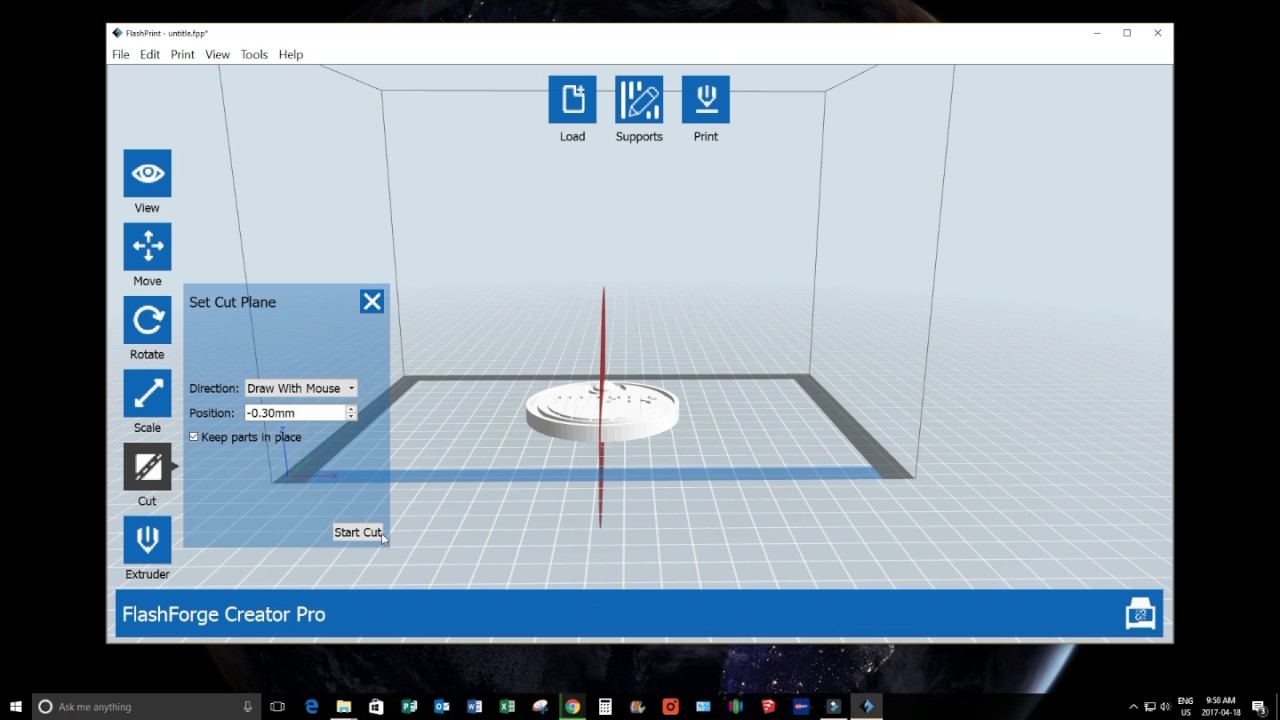

Flashprint Basics

How to Burn Your Own Screens from Home: Screen Print Tutorial

PERFECT Exposure times (calibration) - dial in your 3D printer resin [EASY METHOD]

NEW! | Export LoL models and create your own papercraft templates (Spanish)

5.0 / 5 (0 votes)