The Common Types of Steel Connections

Summary

TLDRIn this video, structural engineer Brendan explains the critical importance of designing proper connections in steel structures. He explores various connection types, including welded and bolted connections, discussing their benefits and drawbacks. Detailed insights are provided into common connections such as fin plate, bearing, and splice connections, along with their impact on the transfer of forces and moments. The video also covers different types of bolts, including S, TB, and TF bolts, and their applications in ensuring structural stability. With tips on optimizing construction efficiency, the video is a valuable resource for engineers working with steel structures.

Takeaways

- 😀 Welded and bolted connections are the two major types of structural connections, each with its own benefits and drawbacks.

- 😀 Welded connections offer direct member joining and moment transfer but may involve time-consuming on-site welding and transport limitations for large structures.

- 😀 Bolted connections are preferred by contractors for faster construction and are typically cheaper, with many types available for different needs.

- 😀 The fin plate connection is a simple connection that generally doesn't transfer moments, but can provide slip and some rigidity, requiring consideration of torque and twist.

- 😀 Bearing connections, common for beam-column joints, can be pin, semi-rigid, or fixed depending on stiffness, and are easy to install with minimal setup time.

- 😀 Base connections, often pinned but potentially made rigid, are crucial for column stability and may include additional bolts for temporary fixity during construction.

- 😀 End plate bearing connections allow for rigid or semi-rigid joining of beams and columns but require precise construction due to limited tolerance in member lengths.

- 😀 Splice connections, used for joining long members, may involve butt welding or bolted plates and require careful design to prevent excessive flexibility.

- 😀 Different types of bolts—S, TB, and TF bolts—are used for various connection types, with friction bolts (TB) offering higher torque for moment connections, reducing shear resistance.

- 😀 Haunch connections, used to increase the depth of connections, improve stiffness and deflection control in large portal frame structures.

- 😀 In structures with smaller elements like mullions, slotted hole fin plate connections allow for lateral force resistance while accommodating vertical movement.

Q & A

What are the two major types of connections in structural design?

-The two major types of connections are welded connections and bolted connections.

What is a significant drawback of using welded connections?

-A significant drawback of welded connections is that they can be time-consuming, either requiring on-site welding or shop manufacturing and transport, both of which can be costly and slow down construction.

Why are bolted connections generally preferred by contractors?

-Bolted connections are preferred by contractors because they are quick to assemble, cheaper, and allow for faster construction as they only require bolting, making them more cost-effective and time-efficient.

What is the typical design approach for a fin plate connection?

-For a fin plate connection, bolts are placed in a line, with the number of bolts typically determined by the depth of the structure. This type of connection is commonly used as a pin connection and does not transfer significant moments.

What is the advantage of a bearing-type connection at the top of a column?

-The advantage of a bearing-type connection at the top of a column is that it is quick and easy to install. The beam sits directly on the column, and the connection can be either pinned, semi-rigid, or rigid depending on the design.

Why is it recommended to have four bolts in the base of a column connection?

-It is recommended to have four bolts in the base of a column connection to provide temporary fixity, which helps steel fabricators set the column in place without needing temporary props, ultimately making the construction process more cost-effective.

What is the challenge with using end plate bearing connections?

-The challenge with end plate bearing connections is the limited tolerance during construction, as the beam must be exactly the right length to fit into the pre-determined location. This makes it harder to accommodate for small discrepancies in the length of the beam or column.

What is a splice connection, and when is it necessary?

-A splice connection is used when two members, such as beams or columns, need to be joined together, typically to extend the length of a structure. It is necessary when members are too long to be transported as a single piece or when there is a need for a joint to handle moment transfer.

What are the different types of bolts used in structural connections?

-The different types of bolts include the S bolt (snug fit with some slip), TB bolt (friction-tightened for better moment resistance), and TF bolt (friction type bolt, which requires surface preparation to increase resistance to slip).

What is the purpose of haunch connections in large portal frame structures?

-Haunch connections are used to increase the depth of the connection, which locally increases the stiffness and the ability to transfer more force. This helps reduce moments and deflections in the design of large portal frame structures.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

The basics of post tensioned concrete design | how to design post-tensioning

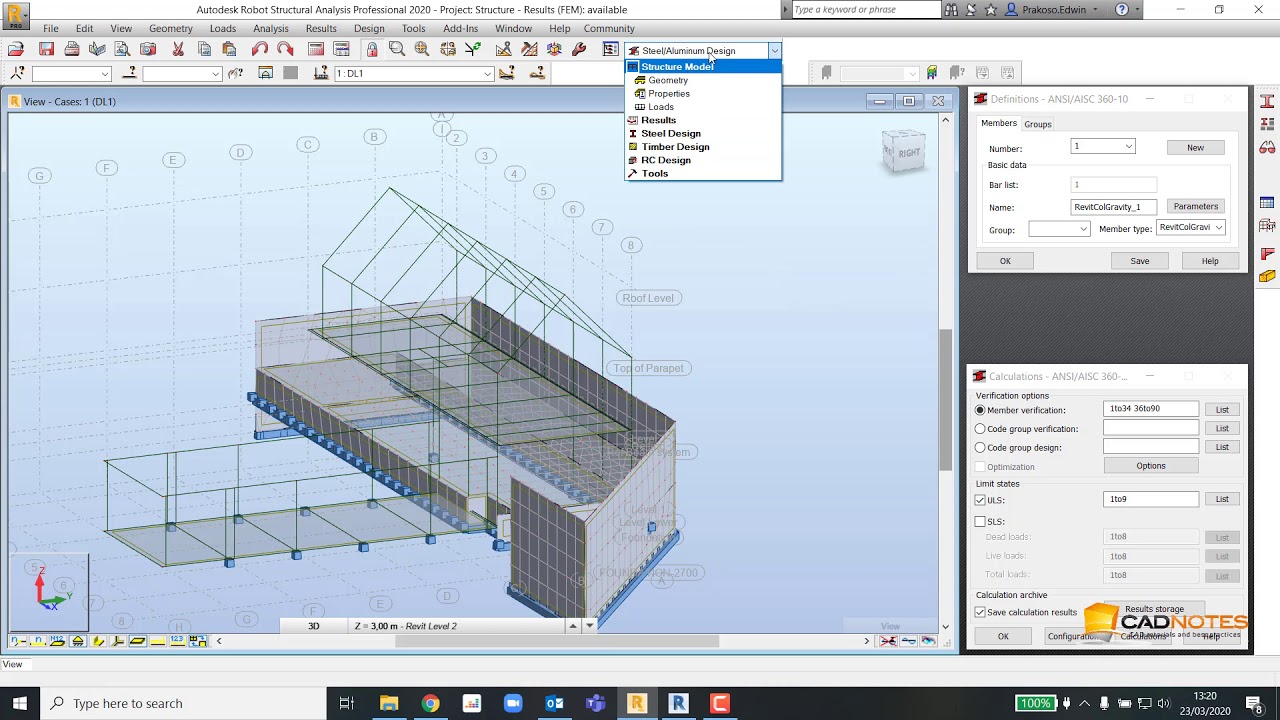

BIM workflow untuk Struktur: Revit dan Robot Structural Analysis

Konsep Dasar Load and Resistance Factor Design (LRFD) pada Struktur Baja | Lightboard

weld metal microstructure

Detail Penulangan Menurut SNI 2847: 2019

Steel Connections Every Structural Engineer Should Know

5.0 / 5 (0 votes)