DWM Sheet Piling & Bracing

Summary

TLDRThis animation demonstrates the pre-drive method of sheet piling installation in the UK, highlighting the use of an excavator-mounted vibratory hammer (EMV) to drive piles. The process involves ensuring site safety, preparing the excavation, and assembling frames for proper alignment. The sheets are carefully driven into the ground, with checks for vertical alignment and following a specific sequence around the excavation perimeter. The installation includes safety precautions such as edge protection and safe access. The method is emphasized as safe and effective for precise sheet piling installation.

Takeaways

- 😀 The pre-drive method for sheet piling in the UK is considered one of the safest methods, especially when using an excavator-mounted vibratory hammer (EMV).

- 😀 Before installation, it is essential to check for buried services and review available service records on the site.

- 😀 Pre-digging to a depth of one meter along the line of the sheet piles is recommended to prepare the site.

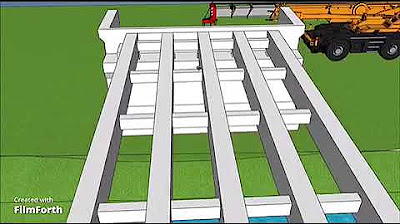

- 😀 The excavation frame should be assembled inside the excavation using an excavator to lower and connect the brace components.

- 😀 Corner piles should be installed first if an interlocked keyframe is required, ensuring they are welded and driven together.

- 😀 The EMV clamps the sheet pile, and once in position, it is driven vertically, ensuring proper alignment using a spirit level.

- 😀 If the sheet pile is not vertically aligned, it should be extracted and repositioned until vertical.

- 😀 The piles are often initially installed to one meter above ground level to facilitate the installation of adjacent piles.

- 😀 The piles can be driven to their final level once the initial alignment is complete, and the frame is pumped out against the piles.

- 😀 A safe means of access must be provided for workers, including safe unloading procedures and edge protection around the excavation.

Q & A

What is the pre-drive method of sheet piling installation?

-The pre-drive method involves using a vibratory hammer, such as an excavator-mounted vibrator (EMV), to drive the sheet piles into the ground before the final installation. This method is considered one of the safest for pre-driving sheets.

Why is it essential to check service records before starting the pre-drive method?

-It is essential to check service records to ensure that all potential hazards, such as existing underground services, are accounted for. This helps avoid accidental damage to utilities and ensures safety during the installation process.

What is the recommended depth for the excavation before installing sheet piles?

-It is recommended to pre-dig up to one meter in depth along the line of the sheet piles, ensuring the area is prepared for the installation of the piles and frames.

How are the frames assembled for the sheet piling process?

-The frames are assembled inside the excavation using an excavator to lower the brace components, which are then connected using pins, clips, or bolts, and plates. These frames are then used as guides for installing the sheet piles.

What is the role of the corner sheets in the sheet piling installation?

-The corner sheets are driven first when interlocked keyframe installation is required. These sheets are welded to the respective piles and driven together, establishing the framework for the perimeter of the excavation.

How do you ensure the proper alignment of the sheet piles during installation?

-The alignment of the sheet piles is checked using a spirit level. If the sheet is not vertically aligned, it should be extracted and realigned until it is vertical.

What is the standard practice for driving sheet piles to the final level?

-Initially, all sheet piles are driven to a height of one meter above ground level to facilitate the installation of adjacent piles. Once the alignment is complete, the piles are driven down to the final level.

Why is edge protection necessary during the installation process?

-Edge protection is necessary to ensure the safety of workers and to prevent accidents, especially during excavation and when installing frames in the excavation. It ensures a safe working environment.

What are the key steps involved in assembling the lower frame for the sheet piling?

-The lower frame is assembled by lowering the bracing legs into the excavation using an excavator. These legs are connected with pins and clips, and the lower frame is pumped out to pressurize the sheet piles.

How do you ensure safety when accessing the excavation site?

-A safe means of access, such as a ladder or scaffold, should be provided to allow safe entry and exit from the excavation. Additionally, edge protection should be installed to prevent accidents during the installation process.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Underwater Constructions | How do Engineers Make Them?

Animasi Pembuatan Jembatan Beton Bertulang Prodi Teknik Sipil F. Teknik Um Sumbar

Filling of Hard gelatin capsules part 1, auger fill principle, vibratory fill principle #pharmaguide

Mantenimiento "Instalando Disco Duro Sólido M2 y Memoria RAM"

Install Windows 10 Enterprise di PC

DROP HAMMER & MINI PILE

5.0 / 5 (0 votes)