Stages In The Process Of Making Ferrous Metal

Summary

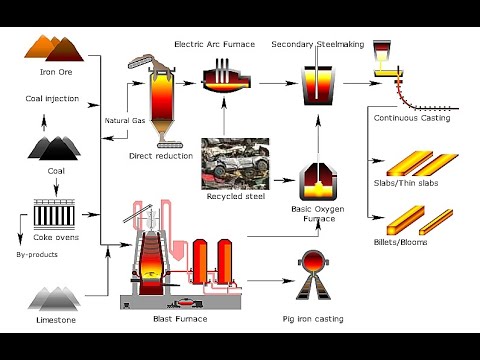

TLDRThis video delves into the intricate stages of iron manufacturing, from the mining of iron ore to the formation of the final product. It begins with the extraction and processing of iron ore, followed by the reduction process in the blast furnace, which produces pure iron. The molten iron is then molded into various shapes. The video highlights the importance of recycling scrap iron to reduce environmental impact and the ongoing technological innovations aimed at improving efficiency and reducing emissions. The iron manufacturing process is a sophisticated and continuous cycle, involving skillful engineering and complex technologies.

Takeaways

- 😀 The iron manufacturing process begins with the mining of iron ore, which is the primary raw material for producing iron.

- 😀 Iron ore is crushed and screened to separate the ferrous metal from other materials, ensuring high-quality iron ore.

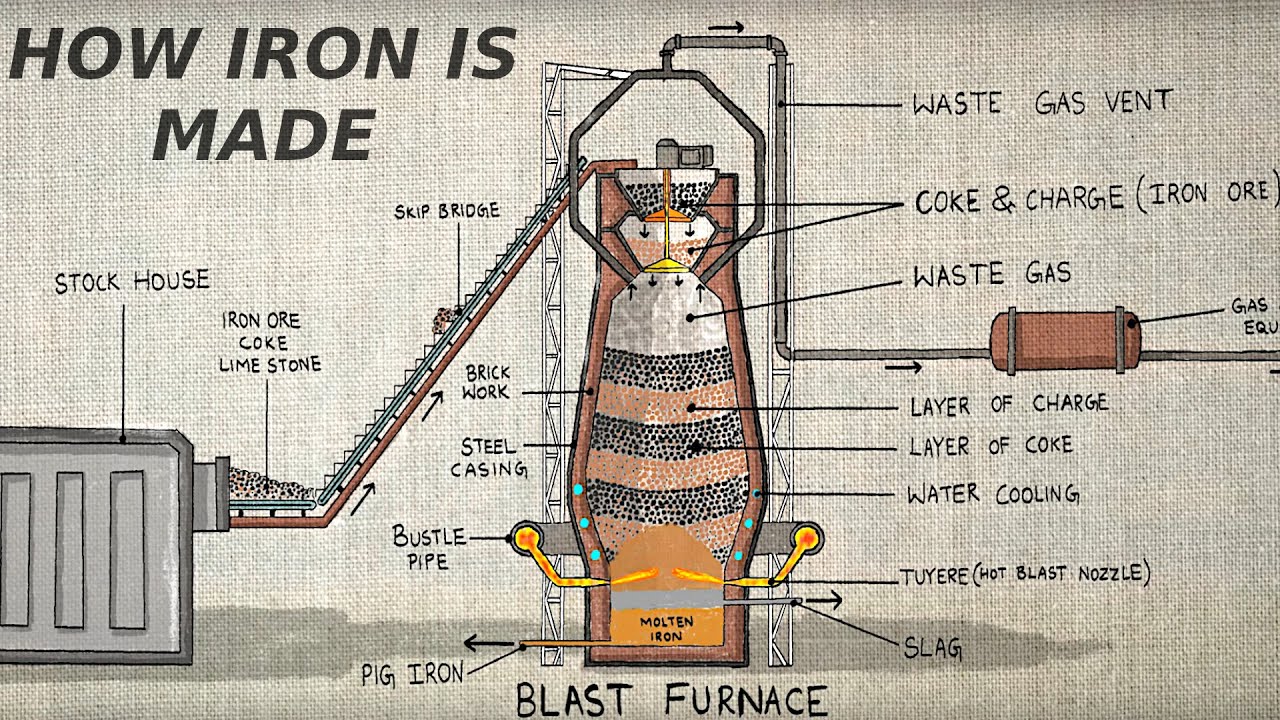

- 😀 The reduction process, which removes oxygen from iron ore, produces pure iron metal, with smelting being a common method used in a blast furnace.

- 😀 In the blast furnace, iron ore, coke, and limestone are heated to high temperatures, and coke acts as a fuel that produces carbon monoxide gas.

- 😀 The process also involves physical and chemical treatments such as stirring, precipitation, and filtration to purify molten ferrous metal.

- 😀 Molten iron is then molded into various shapes, such as blocks, LED sheets, or other forms, through precise temperature control and molding techniques.

- 😀 Iron recycling plays a key role in the industry by reusing scrap iron and waste ferrous metal, which helps reduce environmental impact and conserve resources.

- 😀 New technologies like electric smelting and direct reduction processes are being developed to improve efficiency and reduce emissions in iron production.

- 😀 The iron manufacturing process is a continuous cycle, where scrap iron is recycled back into production to minimize reliance on natural resources.

- 😀 The production of iron is a highly skilled and complex process involving various stages and numerous individuals and companies throughout the iron supply chain.

Q & A

What is the first stage in the iron manufacturing process?

-The first stage in the iron manufacturing process is the mining of iron ore, which serves as the main raw material for iron production.

How is iron ore processed after being mined?

-After being mined, the iron ore is crushed and screened to separate the ferrous metal from other materials. This process uses machines like feeders, crushers, and screens.

What is the purpose of the reduction process in iron manufacturing?

-The reduction process aims to remove oxygen from the iron ore and produce pure iron metal.

What method is commonly used for reducing iron ore to pure iron?

-The most common method for reducing iron ore to pure iron is smelting in a blast furnace.

What materials are added to the blast furnace during the smelting process?

-In the blast furnace, iron ore, coke, and limestone are added together and heated at extremely high temperatures.

What role does coke play in the blast furnace?

-Coke acts as a fuel in the blast furnace, producing carbon monoxide gas which helps reduce the iron ore to iron.

How are other substances removed during the smelting process?

-Other substances are removed through physical and chemical processes, such as stirring, precipitation, and filtration.

What happens to molten iron after the reduction process?

-After reduction, molten iron is poured into molds to form various shapes, such as blocks, ingots, or sheets.

Why is iron recycling important in the iron manufacturing process?

-Iron recycling is crucial because it reduces environmental impact and helps conserve limited natural resources by reusing scrap iron and waste ferrous metal in new iron production.

What new technologies are being developed in the iron manufacturing industry?

-New technologies such as electric smelting and direct reduction processes are being developed to improve efficiency and reduce greenhouse gas emissions in iron production.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

5.0 / 5 (0 votes)