Steel Making and Casting (Principles of Metallurgy)

Summary

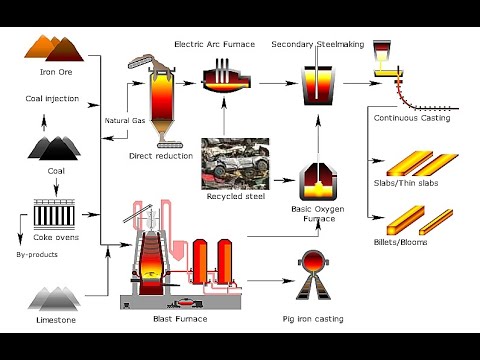

TLDRThis script delves into the fascinating process of steel production, starting from iron ore extraction to the final casting stages. It covers the use of blast and electric arc furnaces, highlighting their roles in creating molten steel. The script also touches on the environmental impact, comparing steel production to the creation of iconic structures like the Eiffel Tower. Furthermore, it explores various casting methods, including sand casting, continuous casting, and ingot casting, each with its unique applications and advantages in steel manufacturing.

Takeaways

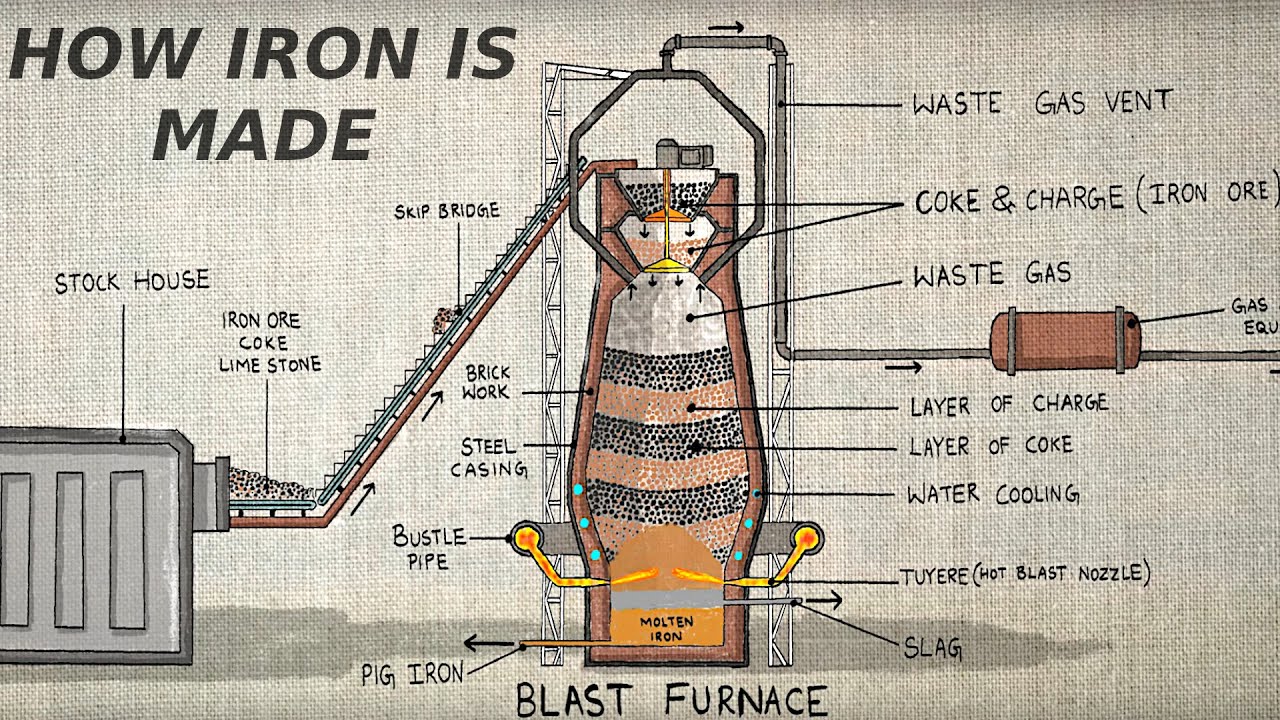

- 🌋 Iron ore, abundant in the Earth's crust, is mined and processed to extract iron, which is chemically bonded to oxygen.

- 💥 In a blast furnace, iron ore is reduced to molten iron at temperatures reaching 2200 degrees Celsius, utilizing a hot air blast.

- 🔩 The molten iron produced contains impurities like sulfur, phosphorus, and silicon, necessitating further processing to make it usable.

- ⚙️ Basic oxygen steelmaking is a primary method for refining molten iron into steel, capable of producing steel for nearly 19 Eiffel Towers every hour.

- 🔥 The electric arc furnace is a versatile alternative for steel production, particularly suitable for specialty steels and recycling scrap metal.

- 🌡️ Both basic oxygen and electric arc furnaces involve precise control over temperature and composition to ensure the quality of the steel.

- 🏗️ Secondary steelmaking further refines steel by adjusting alloy content and removing impurities to meet specific customer requirements.

- 🏺 Casting processes like sand casting, continuous casting, and ingot casting solidify molten steel into various shapes for subsequent shaping or forming.

- ♻️ The electric arc furnace plays a significant role in recycling, capable of melting down the equivalent of one Titanic every hour.

- 🔩 Continuous casting is an efficient process for producing large quantities of steel in various forms like billets, blooms, or slabs.

Q & A

What is the primary source of iron used in steel production?

-Iron ore, which is common in the earth's crust and contains iron chemically bonded to oxygen, is the primary source of iron used in steel production.

How is iron ore prepared before being used in a blast furnace?

-Iron ore is mined, crushed, and then blended with coke and heated to make an iron-rich feedstock called sinter, which is used in the blast furnace.

What is the purpose of the hot air blast in a blast furnace?

-The hot air blast in a blast furnace raises the temperature to approximately 2200 degrees Celsius, facilitating the chemical reduction of iron oxide into molten iron and carbon dioxide.

What is slag and how is it formed during the steelmaking process?

-Slag is a liquid formed when lime combines with impurities during the steelmaking process. It floats on the molten iron and is skimmed off for use in other industries.

How does the basic oxygen steelmaking process refine iron from a blast furnace into steel?

-In the basic oxygen steelmaking process, high purity oxygen is blown onto molten iron to rapidly oxidize carbon, manganese, and silicon, refining the iron and aiding in the melting process.

What is the significance of the electric arc furnace in steel production?

-The electric arc furnace is significant as it allows for the production of steel from cold steel scrap, making it one of the world's largest recycling processes and suitable for specialty steels.

How does the temperature in an electric arc furnace compare to the sun's surface?

-The electric arc furnace reaches temperatures of about 12,000 degrees Celsius, which is twice the temperature of the sun's surface.

What is secondary steelmaking and why is it necessary?

-Secondary steelmaking is used to further refine steel by making fine adjustments of alloys, controlling temperature, and removing gases and impurities to meet customer specifications.

What are the three main methods of casting molten steel and what are their purposes?

-The three main methods of casting molten steel are sand casting, continuous casting, and ingot casting. These methods solidify the molten steel into a suitable profile for shaping or forming into various products.

How does continuous casting differ from ingot casting in terms of efficiency and product type?

-Continuous casting is a more efficient process with a high throughput, suitable for producing long strands of steel in the form of billets, blooms, or slabs. Ingot casting, on the other hand, is better suited for one-offs and small batches, and can produce large ingots with less complexity.

What is the role of silicon in the molten steel during the casting process?

-Silicon is added to molten steel to increase its fluidity, ensuring that the molten metal can completely fill the mold and reduce the risk of solidifying within the mold.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)