3D printing bolt and thread in horizontal or vertical position - strength test

Summary

TLDRIn this video, Igor tests the strength of 3D printed bolts and nuts in different orientations—vertical, horizontal, and at a 45-degree angle. The video covers a series of stress tests, including torque, pulling force, and shear stress, to determine the most optimal 3D printing position for durability. While vertical printing avoids support structures, the results reveal that horizontal prints are stronger, though they require supports. Igor provides insights into the pros and cons of each orientation, offering practical advice on when to use vertical versus horizontal printing based on expected loads. The video concludes with a disclaimer on the limitations of plastic 3D printed parts.

Takeaways

- 😀 The testing process involves three different printed bolt and nut sizes, ranging from N3 to M12.

- 😀 The main question being tested is the optimal position for 3D printing bolts and nuts: vertical, horizontal, or angled.

- 😀 Vertical printing is often recommended as it avoids the need for supports, but there may be weaknesses in the layer adhesion.

- 😀 The experiment focuses on three types of loads: torque, pulling stress, and shear stress to determine the strength of the 3D printed bolts.

- 😀 Shear stress is particularly relevant for plastic bolts because they cannot be tightened as strongly as metal bolts, which would create friction to hold them in place.

- 😀 Calculations show that the plastic bolts' ultimate strength is lower than the test force, indicating they are weaker than expected.

- 😀 The print position plays a significant role in the strength of the bolts, with horizontal printing resulting in stronger bolts than vertical printing.

- 😀 Support structures are necessary for horizontal prints, but they make the printing process more complex compared to vertical prints.

- 😀 The final test results indicate that bolts printed horizontally are much stronger than those printed vertically, although horizontal printing requires more support material.

- 😀 A small disclaimer: the plastic material used (PLA) cannot withstand high temperatures and wears out faster than metal, making it unsuitable for high-load or high-temperature applications.

- 😀 Future videos will continue testing the strength of 3D printed bolts and screw nuts, and will explore the optimal positions for printing them.

Q & A

What is the main objective of Igor's testing in the video?

-The main objective is to determine the optimal printing position for 3D-printed bolts and nuts to achieve the strongest possible results. Igor tests the strength of these parts when printed in vertical, horizontal, and angled orientations.

Which testing methods does Igor use to evaluate the strength of the bolts and nuts?

-Igor uses three primary testing methods: a torque test, pulling force test, and shear stress test to measure how the 3D-printed bolts and nuts hold up under different loads.

Why is the shear stress test important for the plastic bolts?

-The shear stress test is important because, unlike metal bolts, plastic bolts cannot be tightened as strongly due to lower friction. This test helps evaluate how the parts perform under forces that would cause them to slide or shear.

What does Igor discover about the strength of 3D-printed bolts printed in different orientations?

-Igor finds that 3D-printed bolts in horizontal positions are significantly stronger than those printed in vertical positions. However, horizontal printing requires the use of support structures, which are not needed for vertical prints.

What is the trade-off when printing bolts in a horizontal position?

-The trade-off of printing in a horizontal position is the need for additional support structures during the 3D printing process, which can complicate the printing process, though it results in stronger parts.

Why are vertical prints generally easier to create despite their weaker performance?

-Vertical prints are easier to create because they do not require additional support structures. This makes them simpler to print, though they are weaker under stress compared to horizontal prints.

What material is used for 3D printing the bolts and nuts, and what are its limitations?

-The material used for 3D printing the bolts and nuts is PLA (Polylactic Acid). Its limitations include poor performance in high temperatures and faster wear compared to metals, making it unsuitable for high-stress or high-temperature applications.

What does Igor suggest about using 3D-printed bolts for real-world applications?

-Igor suggests that 3D-printed bolts are suitable for low-load applications or as temporary solutions, but they should not be used in critical or high-stress environments, such as on car tires, due to the material's weaknesses.

How does Igor calculate the theoretical maximum strength of the printed bolts?

-Igor calculates the theoretical maximum strength of the printed bolts by using the formula for force (F = stress × area), where he uses the material's ultimate strength (65 megapascals for PLA) and the bolt's cross-sectional area. This gives an estimate of the force the bolt can withstand before breaking.

What future tests does Igor plan to conduct, and why?

-Igor plans to conduct future tests on 3D-printed screw nuts to determine the optimal printing position for them. He believes that the results will differ from the bolt tests and will provide more comprehensive information about the performance of printed fasteners.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

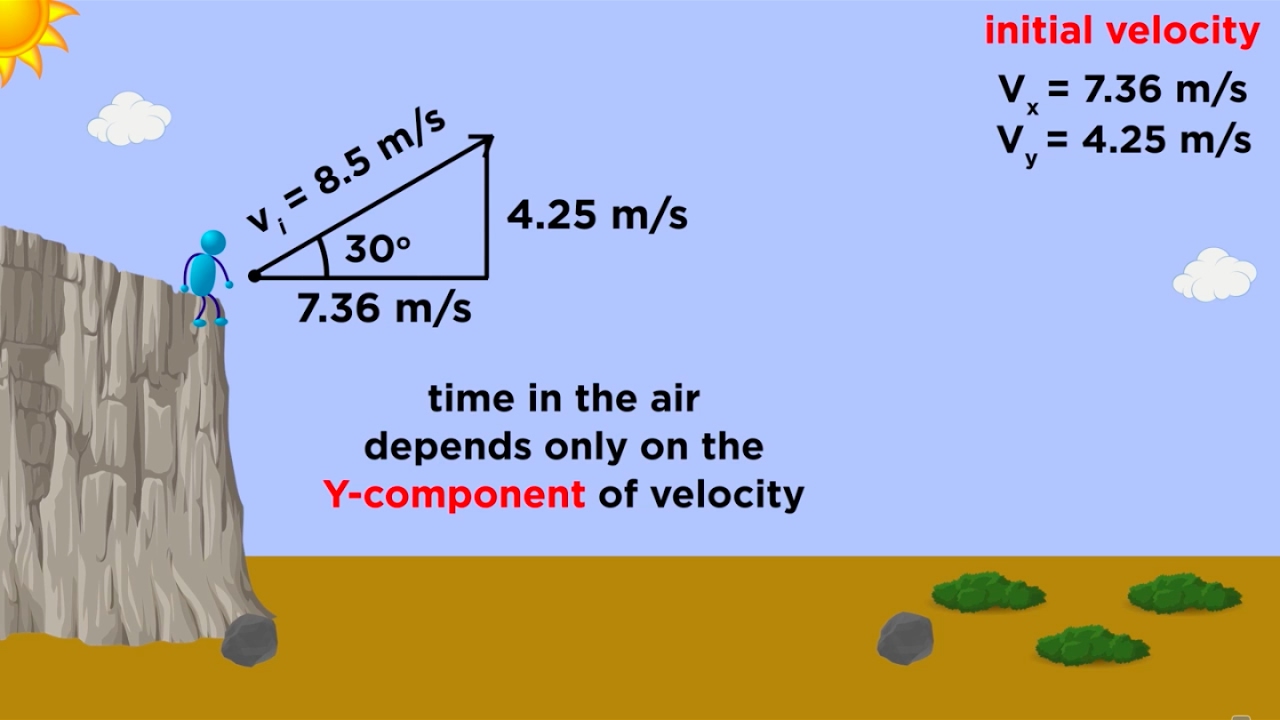

Projectile Motion Part II | Quarter 4 Grade 9 Science Week 2 Lesson

Projectile Motion Launched at an Angle | Height and Range | Grade 9 Science Quarter 4 Week 2

PROJECTILE MOTION | Physics Animation

Kinematics Part 3: Projectile Motion

Projectile Motion (Non-Horizontally Launched) Tagalog Physics Tutorial

ORTHOGRAPHIC DRAWING EXAMPLE

5.0 / 5 (0 votes)