Lab1 Rock Young's modulus E and unconfined compression strength UCS

Summary

TLDRThe video explains how to calculate unconfined compressive strength (UCS) and Young's modulus using cylindrical rock samples. The process involves applying axial loads to the sample and measuring the resulting stress and strain. The workflow consists of four steps: measuring the sample, setting up the loading frame, fracturing the rock, and analyzing the data. Key aspects include ensuring sample quality, controlling the loading process, and calculating parameters from force and displacement data. The results yield Young's modulus from loading/unloading cycles and the UCS as the peak stress the rock can withstand.

Takeaways

- 🧱 UCS and junk modulus are calculated using axial load applied to cylindrical cores.

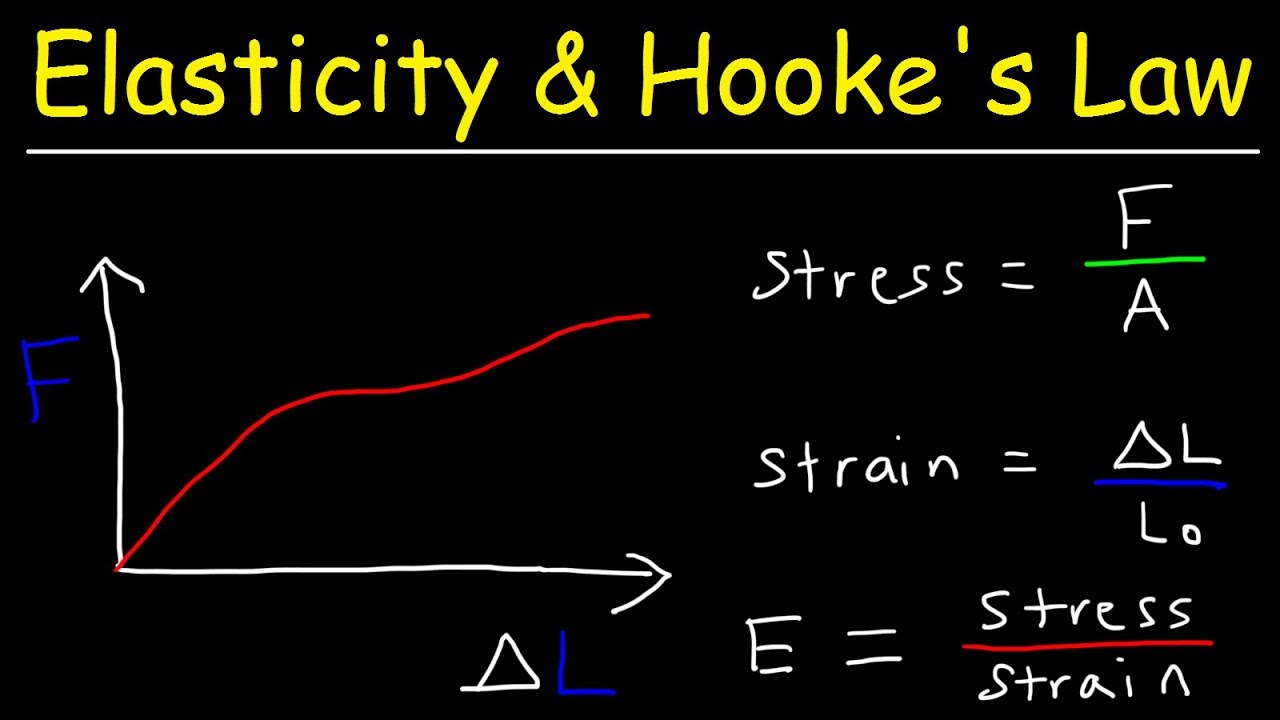

- 📏 Strain is calculated by comparing the change in length (delta L) to the initial length of the sample.

- 📊 Stress is calculated as the applied force divided by the area of the cylindrical sample.

- ⚖️ Junk modulus is determined from the differential stress and differential strain during loading.

- 📈 UCS (unconfined compressive strength) is calculated by finding the peak force the sample can withstand divided by its area.

- 🔍 Step 1 involves measuring and checking the sample’s quality, including verifying if the sample is straight and ensuring the end faces are parallel.

- ⚙️ Step 2 includes setting up the loading frame and confirming that the stress applied is parallel to the sample’s axis.

- 🪨 Step 3 involves fracturing the rock by increasing force and then analyzing the load-displacement data.

- 📑 Step 4 is data analysis, converting force and displacement into stress and strain to calculate the junk modulus and UCS.

- 🔬 The final parameters obtained are junk modulus during loading and unloading and UCS from the peak stress point.

Q & A

What are UCS and Young's modulus, and how are they determined?

-UCS (Uniaxial Compressive Strength) and Young's modulus are determined using cylindrical rock samples. UCS is the maximum stress the sample can withstand before breaking, while Young's modulus measures the stiffness of the rock. Both are determined by applying an axial load to a cylindrical core and calculating stress and strain.

What are the four steps involved in calculating UCS and Young's modulus?

-The four steps are: 1) measuring the sample, 2) setting up the loading frame, 3) fracturing the rock, and 4) analyzing the data.

Why is it important to check the quality of the rock sample before testing?

-It is important to check the quality to ensure the sample is suitable for testing, as samples need to be as close to perfectly cylindrical as possible. Measurements such as the diameter and length are taken to verify uniformity and parallelism of the end faces.

How is stress calculated during the experiment?

-Stress is calculated as the force applied over the cross-sectional area of the cylindrical sample.

How do you determine whether a sample is straight?

-A sample is considered straight if the diameter measurements taken at different parts of the sample are nearly the same. The average of these measurements is used to represent the diameter.

What role does the loading frame play in the experiment?

-The loading frame is used to apply a controlled force to the cylindrical sample. It ensures that the applied stress is parallel to the axis of the sample, and allows the measurement of load and displacement.

What are channels 1 and 3 used for during the experiment?

-Channel 1 is used to measure the load (force) applied to the sample, while Channel 3 measures the vertical displacement of the sample.

What is the purpose of using a protective plastic around the sample?

-The protective plastic is used to prevent injury or damage if the sample fractures and fragments are ejected during the experiment.

How is the Young's modulus calculated during the experiment?

-Young's modulus is calculated as the slope of the stress-strain curve, either during loading or unloading. It is the differential stress divided by the differential strain.

What is the significance of the peak stress in the experiment?

-The peak stress represents the maximum force the sample can withstand before fracturing, which is used to determine the UCS of the rock.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

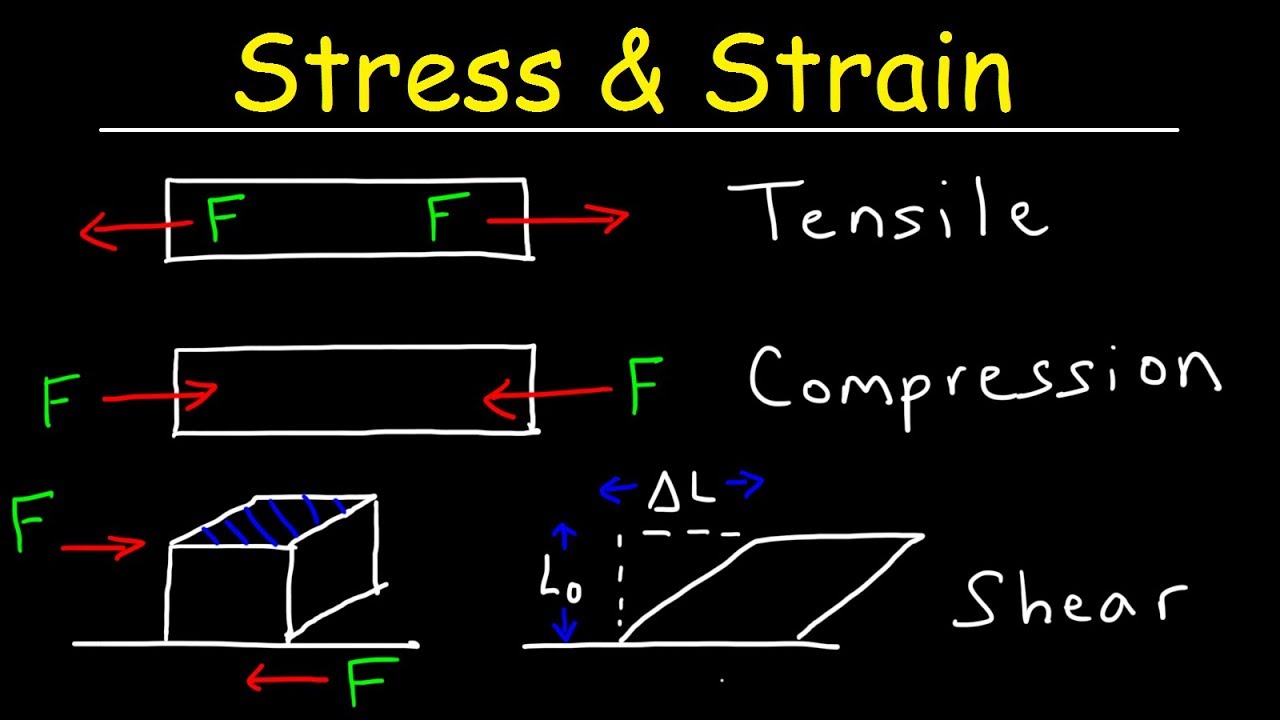

Tensile Stress & Strain, Compressive Stress & Shear Stress - Basic Introduction

Lab 2 Rock tensile strength: Brazilian test

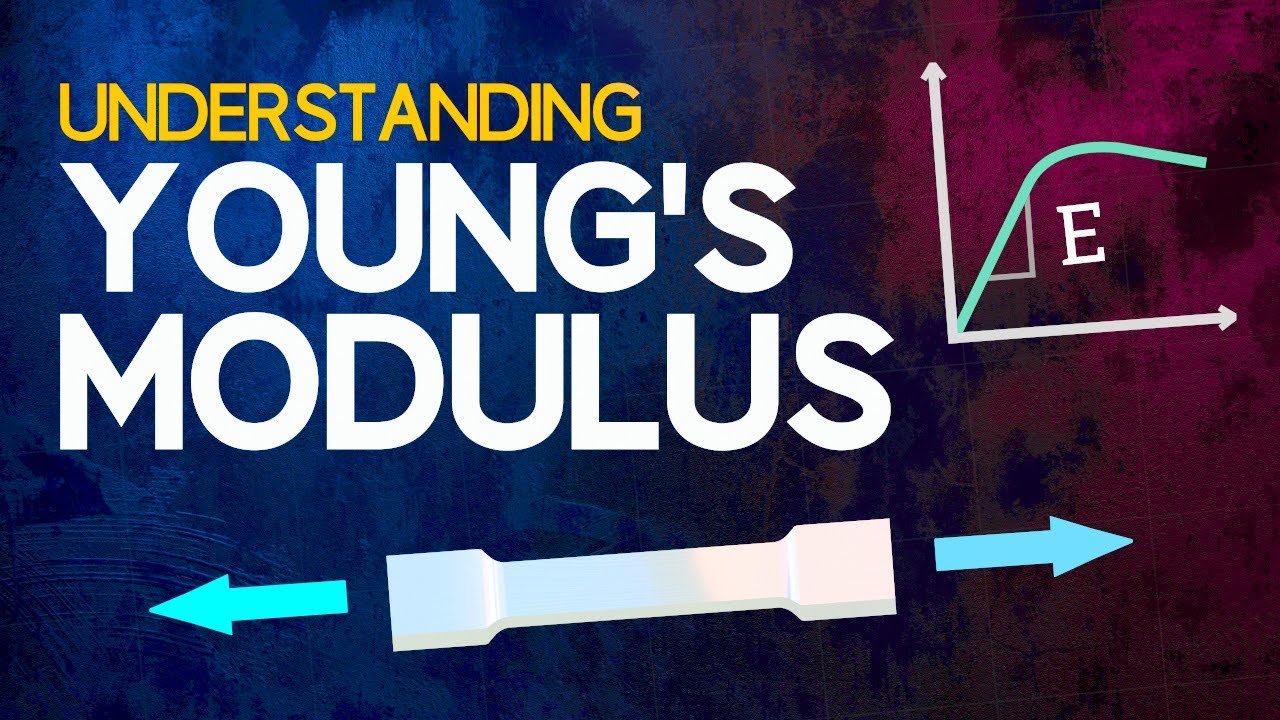

Understanding Young's Modulus

TEKNIK UJI KUAT TEKAN BETON | ANAK TEKNIK

Thermal Stresses And Strain in Hindi || Thermal Stress kya hoti hai

Elasticity & Hooke's Law - Intro to Young's Modulus, Stress & Strain, Elastic & Proportional Limit

5.0 / 5 (0 votes)