Lec 19: Plant Layout: Types of Layout

Summary

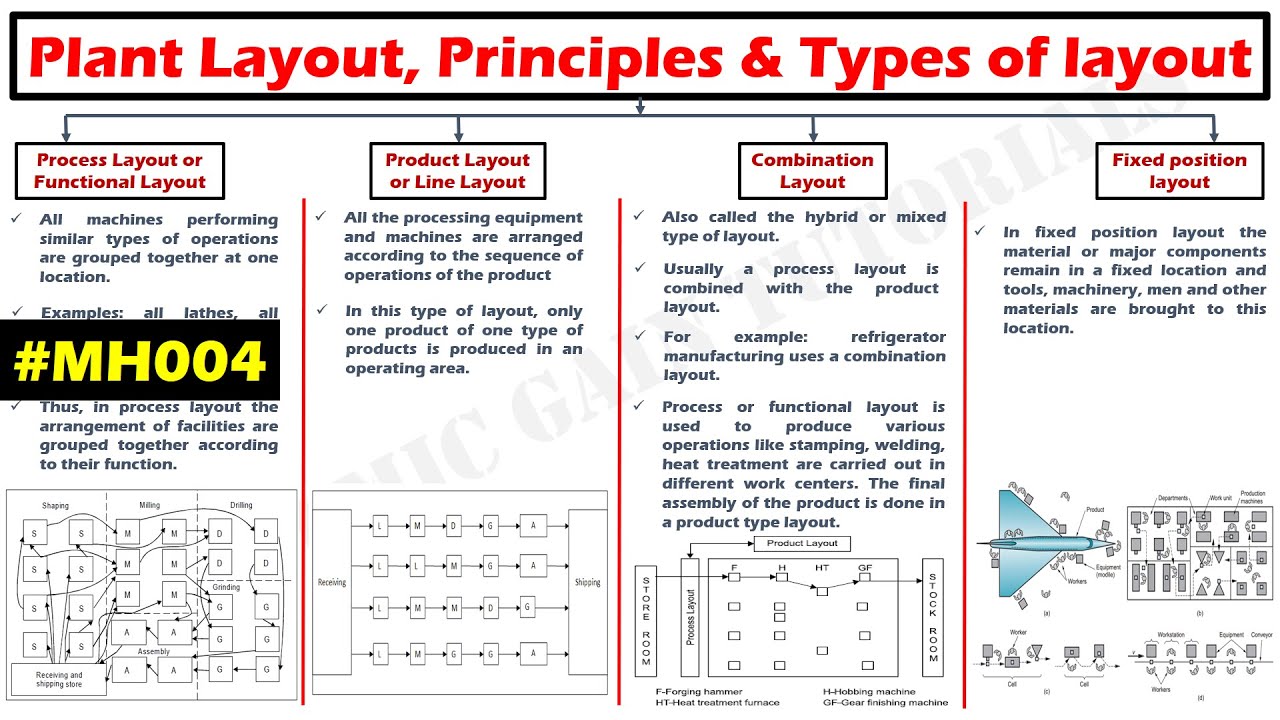

TLDRThis presentation delves into the principles of Industrial Engineering, focusing on plant layouts and their impact on production efficiency. It discusses various layout types, including process, product, combination, fixed, and cellular layouts, each tailored to different production volumes and product variety. The product layout is highlighted for high-volume, limited variety production, offering advantages like smooth material flow and efficient resource utilization but with drawbacks like inflexibility to design changes. The combination layout is introduced as a middle ground for moderate volumes and variety, while the fixed layout is suitable for large, immobile structures. The talk concludes with a comparison of layout costs and their justification based on production volume.

Takeaways

- 🏭 The plant layout is crucial for arranging machines and facilities to ensure a smooth flow of resources, minimize costs, and maximize output with minimal wastage.

- 🔄 There are five main types of layouts: process layout, product layout, combination layout, fixed layout, and group layout (cellular layout).

- 🔧 Product layout is ideal for high-volume production with limited product variety, utilizing specialized machines arranged in the sequence of processing jobs.

- 🔩 The advantage of product layout is a smooth, linear flow of materials, which allows for mechanized material handling, reduced production time, and effective use of space and resources.

- ⚙️ A disadvantage of product layout is its inflexibility; a single machine failure can halt the entire production line, and design changes require significant layout modifications.

- 🛠️ Combination layout combines features of both process and product layouts, suitable for moderate volumes and a variety of products, like manufacturing different types of gears.

- 🏗️ Fixed layout is characterized by a stationary major component or material, with all necessary resources brought to it for processing, commonly used in construction and shipbuilding.

- 💼 Investment in fixed layout is minimal, and it offers a sense of achievement and expertise to workers, but it's not suitable for high-volume production.

- 📈 The total cost for process layout is initially low with high variable costs, while product layout has high fixed costs but lower variable costs, making it more cost-effective for high volumes.

- 📊 The choice between process and product layout depends on the volume of production; process layout is justified for low volumes, while product layout is for high volumes.

Q & A

What is the primary goal of plant layout?

-The primary goal of plant layout is to arrange machines and facilities in a way that ensures a smooth flow of resources for producing goods and services at the lowest possible cost with the highest output and minimum wastage of resources.

How does the marketing strategy of a company influence plant layout?

-The marketing strategy of a company influences plant layout by determining whether the company will focus on producing a few units at very high volumes or a wide variety of products in limited quantities. This decision affects the manufacturing strategy and the development of production facilities.

What are the five types of layouts mentioned in the script?

-The five types of layouts mentioned in the script are process layout, product layout, combination layout, fixed layout, and group layout (also called cellular layout).

What is a product layout and when is it suitable?

-A product layout is suitable when a company can afford to produce a high volume of a limited variety of products. It involves arranging machines or facilities in the sequence of processing jobs, allowing for continuous and linear flow of materials from start to finish.

What are the advantages of a product layout?

-The advantages of a product layout include a smooth, linear flow of materials, which allows for the implementation of mechanized material handling systems, minimum time for production, minimum in-process inventory, minimum congestion, and effective use of space, machines, and manpower.

What are the disadvantages of a product layout?

-The disadvantages of a product layout include the critical failure of even a single machine which can halt the entire production process, lack of flexibility to accommodate design changes or variations in production rate, and the need for high investment in specialized machines.

What is a combination layout and how does it differ from a product layout?

-A combination layout is a hybrid layout that combines the features of both process and product layouts. It is suitable for producing a variety of products in moderate volumes. Unlike a product layout, which is suitable for high volumes of limited variety, a combination layout can handle both variety and moderate volumes.

What is a fixed layout and where is it commonly used?

-A fixed layout is a type of layout where the location of a major part or component is fixed, and all machines, labor, and materials are brought close to it for processing. It is commonly used in industries like construction, shipbuilding, and house building where heavy structures are developed.

What are the benefits of a fixed layout?

-The benefits of a fixed layout include limited investment in the layout itself and the opportunity for workers to gain experience and expertise, leading to a sense of accomplishment and pride in their work.

How does the total cost vary between process layout and product layout?

-The total cost for a process layout is generally lower due to lower fixed costs, but the variable costs are higher. In contrast, the total cost for a product layout is higher due to higher fixed costs, but the variable costs are lower. For low volumes, the process layout is more cost-effective, while for high volumes, the product layout becomes more justified.

What factors determine whether a company should choose a process layout or a product layout?

-A company should choose a process layout if it needs to produce a variety of products in limited volumes, as it offers lower fixed costs but higher variable costs. A product layout is more suitable for high volume production of limited variety products, where the fixed costs are high but variable costs are low.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Lec 20: Plant Layout: Cellular and Process Layout

INDUSTRIAL ENGINEERING: AN INTRODUCTION

#MH004 Plant Layout, Principles of plant layout & Types of layout.

Types of Plant Layout, Explanation with Advantages and Dis-advantages, Plant layout part 2

Size Reduction || Hammer Mill & Ball Mill Complete|| Part-3|Unit-1| P Engineering | B.pharma 3rd sem

MODELOS DE PRODUÇÃO - TAYLORISMO - FORDISMO - TOYOTISMO

5.0 / 5 (0 votes)