FLL SuperPowered Judging Session Presentation - Robot Design - Lazer Robotics

Summary

TLDRLaser Robotics shares a five-year journey of robot design evolution, from an unbalanced, bulky model to a compact, efficient, and stable 13th version. They emphasize improvements in design, navigation, and programming, using Python for complex code and PID logic for error correction. The presentation highlights the use of passive mechanisms, gravity, and strategic design for mission efficiency, showcasing their success in completing 15 missions in 2.5 minutes with a high score.

Takeaways

- 🚀 The Laser Robotics team has been continuously improving their robot design over the past five years, with the Laserbot 13 being their latest iteration.

- 🔄 Each year, they learned from the inefficiencies of the previous design to enhance the next version, demonstrating a commitment to iterative improvement.

- 🏆 The team has achieved success in competitions, winning awards such as the robot design award in qualifiers and states, and the states in robot game and qualifier.

- 🔄 The design evolution focused on making the robot more compact, symmetric, and stable, with a lower center of gravity for better performance.

- 🛠️ The robot's design incorporates thin wheels, a compact form, durability, hidden wires, and symmetrical balance for field navigation and stability.

- 🔩 The robot's attachments are designed to be easily and efficiently attached and secured using gravity and upgraded facing axles, enhancing the robot's functionality.

- 🔧 The team uses passive mechanisms and 360-degree capabilities in their attachments to maximize the robot's efficiency and versatility.

- 💻 They have transitioned to using Spike Prime Python for programming, which allows for more complex code and better error correction.

- 🔍 The team implemented a PID logic system for error correction, which includes proportional, integral, and derivative components for smooth and accurate robot movement.

- 📊 They have a systematic approach to testing and selection, using performance scores based on success rates to choose the most practical and consistent hardware or software solutions.

- 🔄 The team's strategy includes leveraging line following and reducing travel distance to complete missions more efficiently, as demonstrated in their high-scoring performance in competitions.

Q & A

What is the main focus of the Laser Robotics presentation?

-The main focus of the presentation is to share the evolution of the Laserbot 13 design over five years and provide advice on how to improve robot charging sessions and overall robot performance.

How did the design of the Laserbot change from the first to the second year?

-From the first to the second year, the design of the Laserbot evolved from a bulky and unbalanced tutorial model to a more symmetric and balanced robot, although the charging port was over-engineered.

What was the significant improvement in the third year of the Laserbot's development?

-In the third year, the Laserbot was made completely original, extremely compact, allowing for easy drop-down attachments, and included hidden wires, which led to winning the robot and design award in qualifiers and states.

What adjustments were made to the Laserbot in its fourth version to improve its performance?

-In the fourth version, the Laserbot was made taller with a higher center of gravity, which resulted in winning the states in the robot game and qualifier.

What are some of the key features of the 13th version of the Laserbot?

-The 13th version of the Laserbot has improved stability with a lowered center of gravity, a systematic evaluation of its design, and it won the qualifier and states.

What dimensions does the Laserbot 13 have, and how do they contribute to its design?

-The Laserbot 13 has dimensions of 17 by 18 square inches, which, along with thin wheels and a compact design, contribute to its stability without sacrificing space.

How does the Laserbot 13 utilize color sensors for improved performance?

-The Laserbot 13 uses two color sensors for better field navigation, enhancing its ability to navigate and perform tasks on the field.

What is the advantage of the drop-on attachment system in the Laserbot 13?

-The drop-on attachment system in the Laserbot 13 is advantageous because it uses gravity for easy attachment and upgraded facing axles for secure locking, making it efficient and reliable.

What programming language and approach does the team use for the Laserbot's operation?

-The team uses Spike Prime Python for programming the Laserbot, which allows for more complex code and is a better alternative to block coding.

How does the team implement error correction in their robot's programming?

-The team uses a PID (Proportional, Integral, Derivative) logic system for error correction, which allows for maximum smoothness and accuracy in robot navigation.

What strategies does the team use to test and improve the Laserbot's performance?

-The team tests the robot's performance by conducting line navigation tests at different speeds and with or without attachments, recording the success rate and using it as a performance score to select the most practical and consistent options.

How do the team's design choices for attachments contribute to the efficiency of the Laserbot?

-The team uses passive mechanisms and designs attachments to utilize the 360-degree capabilities of the robot, employing gears that lock into place and motors for multiple functions, which increases the efficiency and versatility of the attachments.

What is the significance of using one-way doors in the Laserbot's design?

-One-way doors are used as a type of passive mechanism to lock onto objects or missions without the use of motors, providing an easy way to bring up or drop off units around the map.

How does the team ensure alignment accuracy during missions?

-The team uses alignment mechanisms to align with the bases of missions for accuracy, which is crucial for the successful completion of tasks.

What is the process for designing a trip with the Laserbot?

-The process involves designing an attachment, programming it, testing it for errors, and repeating the process until the most efficient and reliable design is achieved.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

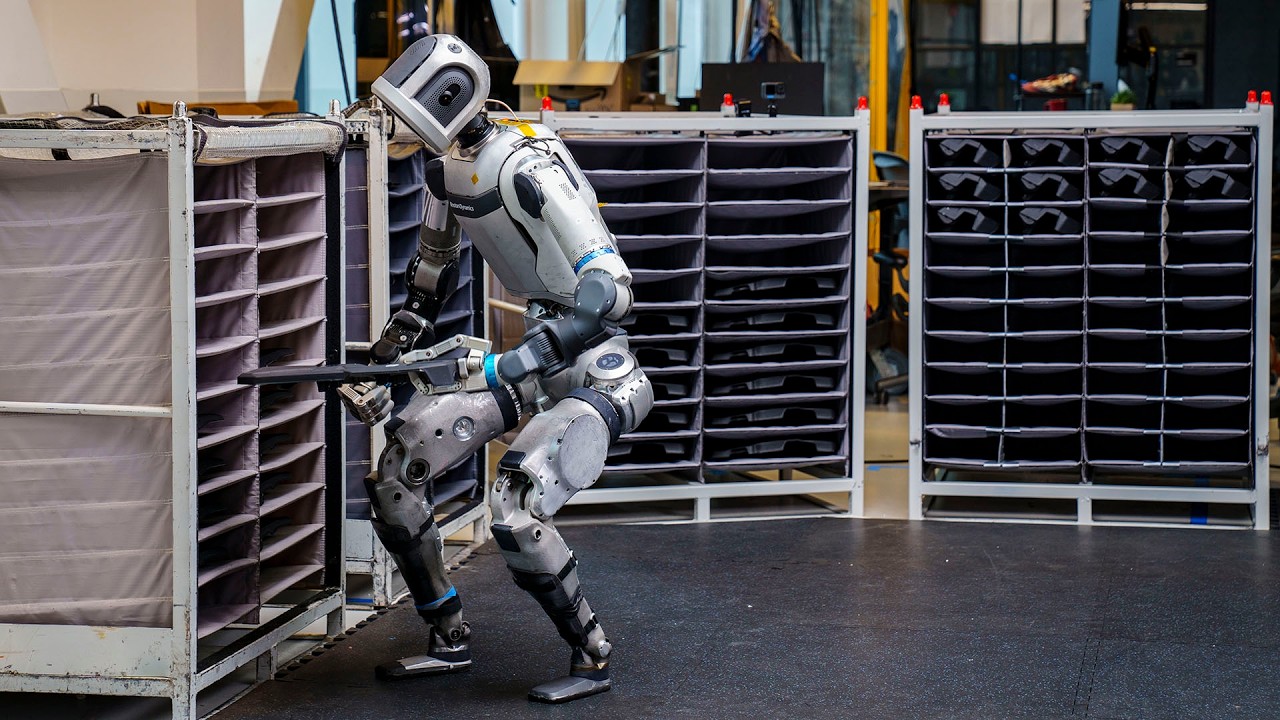

Pick, Carry, Place, Repeat | Inside the Lab with Atlas

What does 3 Generations of Yonex Arcsaber 7 Development Tell Us - ArcFest special

Boston Dynamics Spot Robot | All of its Engineering SECRETS!

5 Years of Roblox game development in 8 minutes

An Introduction to ROS, the Robot Operating System: Intro to ROS (2/6)

Survival Tips for New Startup Entrepreneurs | Keshav Chintamani | TEDxRWTHAachen

5.0 / 5 (0 votes)