Tank Cleaning Procedures

Summary

TLDRThis instructional video covers the essential procedures for cleaning cargo tanks, pumps, and lines on chemical and oil tankers. It highlights the risks of using seawater, chlorine, acids, and bleach on stainless steel, and emphasizes the importance of using fresh water when possible. The script also addresses the cleaning techniques for various cargo residues such as sulfuric acid, isocyanates, and latex. Special handling precautions, safety measures, and operational guidelines are discussed to prevent damage and ensure the proper functioning of cleaning systems. The video aims to equip personnel with the necessary knowledge to maintain tank cleanliness while adhering to safety protocols.

Takeaways

- 😀 Proper cleaning of cargo tanks, pumps, and associated lines is essential for meeting carriage standards, particularly on chemical tankers.

- 😀 Seawater, when used for cleaning, should be taken from an open sea way to avoid contamination, and fresh water is preferred to reduce damage from saltwater chlorine and acids.

- 😀 Stainless steel tank linings and pump components are highly susceptible to damage from saltwater chlorine, bleach, and acids if not handled properly.

- 😀 Bleach and acids, such as sulfuric acid, can be extremely aggressive towards stainless steel and must be used with caution, following specific procedures outlined in manuals.

- 😀 Cleaning with freshwater is preferable to avoid corrosion risks; however, freshwater generators must be efficient enough to meet the cleaning demands.

- 😀 Phosphoric acid, when used for cleaning, may introduce impurities and sediment that can damage pump seals and components, requiring careful monitoring and purging.

- 😀 Isocyanates like TDI and MDI solidify upon contact with water, requiring careful maintenance of a nitrogen blanket during cleaning to prevent complications.

- 😀 Special cleaning procedures are required for certain products like latex, which can solidify and damage pumps if not handled carefully.

- 😀 Personal protective equipment (PPE) and proper monitoring of tank atmospheres are crucial to ensure the safety of personnel during cleaning operations.

- 😀 Slop water, particularly from saltwater or acidic residues, should not be stored in stainless steel tanks, and different types of slops must be managed carefully for disposal.

- 😀 The cleaning process must be carefully controlled to avoid potential damage to equipment and ensure the safe and effective removal of residues, particularly in sensitive tanks like those carrying sulfuric acid.

Q & A

What is the primary focus of this lesson?

-The lesson primarily focuses on the procedures for tank cleaning, including the cleaning of tanks, pumps, and associated lines. It also addresses the risks of seawater chlorine, acids, and other chemical products on stainless steel components.

Why is tank cleaning especially important on parcel chemical tankers?

-On parcel chemical tankers, proper cleaning is crucial to meet carriage standards and prevent damage to tank linings and stainless steel pumps and piping, which could be caused by improper handling of various chemical products.

How does seawater affect stainless steel during tank cleaning?

-Seawater, particularly its chlorine content, can be very aggressive towards stainless steel, leading to corrosion and damage to tank linings, pumps, and piping, especially if the cleaning process is not carefully managed.

What is the preferred method for cleaning tanks, and why?

-The preferred method is using fresh water, as it avoids the risks associated with saltwater, such as corrosion from seawater's chlorine content. However, freshwater generators are only recently efficient enough to meet the cleaning demands.

What should be done if fresh water is unavailable for cleaning?

-If fresh water is unavailable, saltwater can be used for cleaning, but it should be taken from an open sea way to avoid contamination from impurities. Afterward, thorough flushing with fresh water is necessary to remove any traces of salt.

What precautions should be taken when using bleach in tank cleaning?

-Bleach should be diluted and applied according to the vessel's operations manuals and suppliers' guidelines. It is extremely aggressive towards stainless steel and can cause significant damage if not properly managed.

Why is sulfuric acid considered dangerous during tank cleaning?

-Sulfuric acid poses significant risks because it increases in temperature when mixed with water, accelerating corrosion. Proper handling and rapid dilution of the acid are essential to minimize damage during the cleaning process.

What is the role of nitrogen blankets in cleaning sulfuric acid residues?

-A nitrogen blanket can be applied to prevent chemical reactions between sulfuric acid residues and any condensation in the tank. It helps maintain a controlled environment to reduce the risk of dangerous reactions.

How should isocyanates be handled during tank cleaning?

-Isocyanates like TDI and MDI solidify when in contact with water, creating large volumes of gas. It is crucial to maintain a nitrogen blanket during cleaning to prevent any moisture from coming into contact with residues, as it can be extremely difficult to remove solidified isocyanates.

What are the potential risks of cavitation when handling latex cargo?

-Cavitation can cause bubbles to form around the pump impeller, generating heat and causing the latex to solidify, which can seize the pump. To prevent this, it is essential to run the cargo pump in a controlled manner during discharge.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

How An Oil Tanker Works And Designed

Framo pump working system on the ship.

Multi-Purpose Heavy Lift and General Cargo - Introduction to upcoming lectures

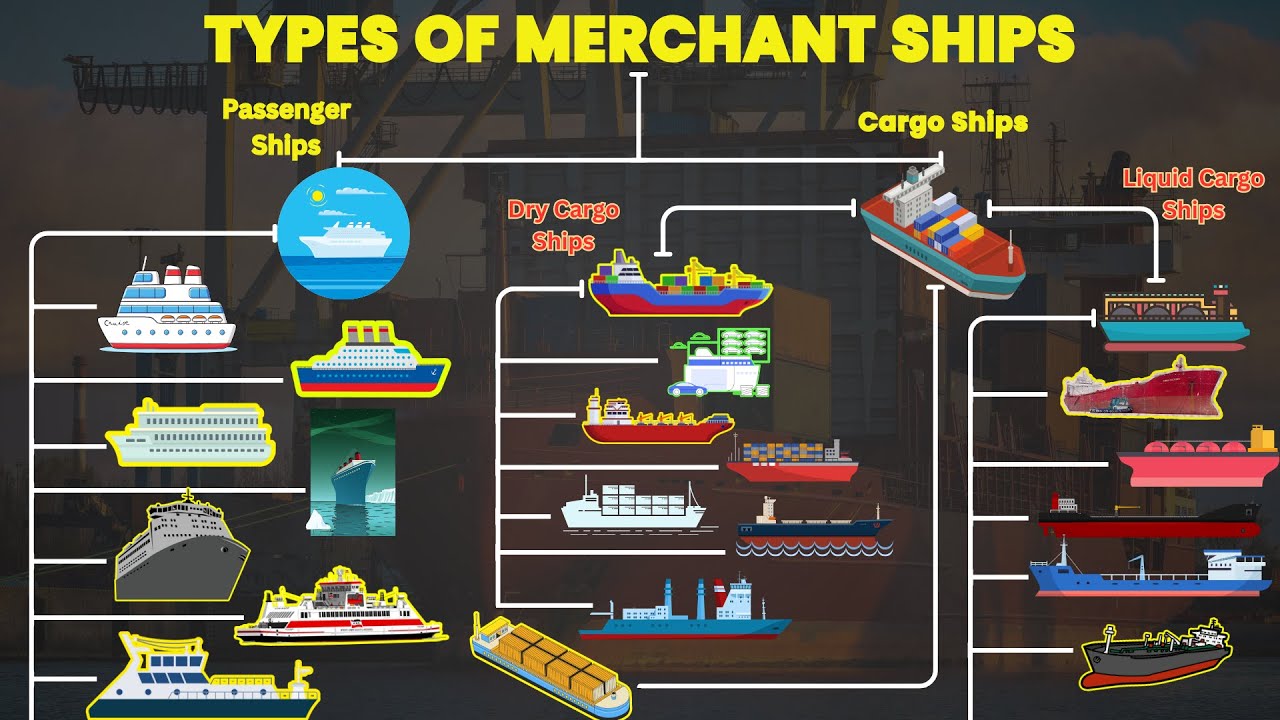

Different Types and Sub-Types of Merchant Ships

The Alfa Laval system for producing high-quality inert gas for cargo ships

MARITIME ENGLISH - TYPES OF VESSELS - PART 1

5.0 / 5 (0 votes)