What is automatic tank gauging system?

Summary

TLDRThis tutorial covers the technical aspects of tank gauging systems, focusing on radar tank gauging and hybrid systems used in various industries such as petrochemicals, oil, and aviation. It explains the purpose and applications of tank gauging in areas like inventory management, custody transfer, and leak detection. The video explores various measurement techniques, including radar, float and tape gauges, and hydrostatic systems, emphasizing their advantages for precise, maintenance-free measurements. The role of hybrid systems in calculating density and volume, as well as the importance of accurate data for operational efficiency, is also discussed.

Takeaways

- 😀 Tank gauging systems ensure accurate level, pressure, and temperature measurements for oil movement, inventory control, and overfill prevention.

- 😀 Tank gauging is widely used in industries like petrochemical, chemical storage, air fueling, refineries, and fuel depots.

- 😀 Storage tanks come in various designs including fixed roof, floating roof, and pressurized tanks, each serving different purposes in liquid storage.

- 😀 Radar tank gauging is a modern method that uses microwaves to measure liquid levels without direct contact with the liquid, minimizing maintenance requirements.

- 😀 Radar gauges operate in the 10 GHz frequency range, allowing for accurate measurement of liquids like asphalt and cryogenic gases such as LNG.

- 😀 Radar tank gauges come with different antenna designs, including horn and parabolic antennas, optimized for specific tank designs and conditions.

- 😀 Hybrid tank gauging systems combine traditional tank gauging with hydrostatic tank gauging to measure mass and density more accurately, reducing labor and measurement errors.

- 😀 The hybrid system can measure density online, making it easier to calculate transferred volume and standard volume without manual intervention.

- 😀 Automatic tank gauging systems are critical for precise inventory management and custody transfer, where accurate net volume calculations are essential.

- 😀 Leading manufacturers of automatic tank gauging systems include Motherwell Tank Gauging, Rosemount, Honeywell, and Endress+Hauser.

- 😀 The video encourages viewers to subscribe for more content related to tank gauging systems and to stay updated with new tutorials and information.

Q & A

What is tank gauging?

-Tank gauging is the process of measuring liquid levels in large storage tanks to determine product volume. It involves ensuring accurate measurements of level, pressure, and temperature to manage oil movement, inventory, and prevent overfills, ensuring efficient operations.

Where is tank gauging commonly used?

-Tank gauging is widely used in industries such as the petrochemical industry, distribution terminals, pipeline terminals, air fueling storage at airports, refineries, and chemical storage. It is commonly applied in tank farms and various types of storage tanks.

What types of storage tanks are used in tank gauging?

-The types of storage tanks include atmospheric tanks (e.g., fixed roof tanks, floating roof tanks), pressurized tanks (e.g., spherical or horizontal cylinders), and cryogenic tanks. Each type of tank requires specific gauging techniques.

What is the main purpose of a tank gauging system?

-The main purpose of a tank gauging system is to transmit tank data from the tank farm to users in a reliable and fast manner. It ensures accurate measurement for inventory management, product movement, mass balance, loss control, leak detection, and overfill prevention.

What are the different tank gauging techniques?

-Tank gauging techniques include manual gauging, float and tape gauges, servo gauges, and radar gauges. Each method has specific applications, with radar gauging being one of the most recent and advanced techniques.

How does radar tank gauging work?

-Radar tank gauging uses microwaves to measure product levels in storage tanks. The device transmits radar signals that reflect off the liquid surface, and the distance traveled by the signal is calculated to determine the liquid level.

What are the advantages of radar tank gauging?

-Radar tank gauging has no moving parts, making it highly reliable and low-maintenance. It can measure a wide variety of liquids, including heavy asphalt and cryogenic gases, and does not require direct contact with the liquid.

What types of radar gauges are available?

-There are several types of radar gauges, including horn antennas for fixed roof tanks, parabolic antennas for tanks with heavy condensation, and still pipe gauges for tanks with still pipes, such as those used for crude oil or gasoline.

What is a hybrid tank gauging system?

-A hybrid tank gauging system combines traditional tank gauging with hydrostatic tank gauging (HTG). It is used primarily in the petroleum industry to measure both mass and density, allowing for more accurate calculations of transferred volume and density without manual measurement.

What is the role of a hybrid system in custody transfer and inventory management?

-In custody transfer and inventory management, hybrid systems ensure the highest accuracy in volume measurement by compensating for temperature and tank characteristics. These systems transfer data directly to master software or DCS systems, providing precise inventory and transfer information.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Shock Verdict: Toyota Prado vs GWM Tank 500 in $80K 4WD Showdown

Introduction To DBMS - Database Management System | What Is DBMS? | DBMS Explanation | Simplilearn

Porque entra ar na rede de aquecedor solar, evite esse defeito em sua instalação.

How to Win at Forex Trading as a BEGINNER

Jalur Instalasi Air Bersih di Gedung

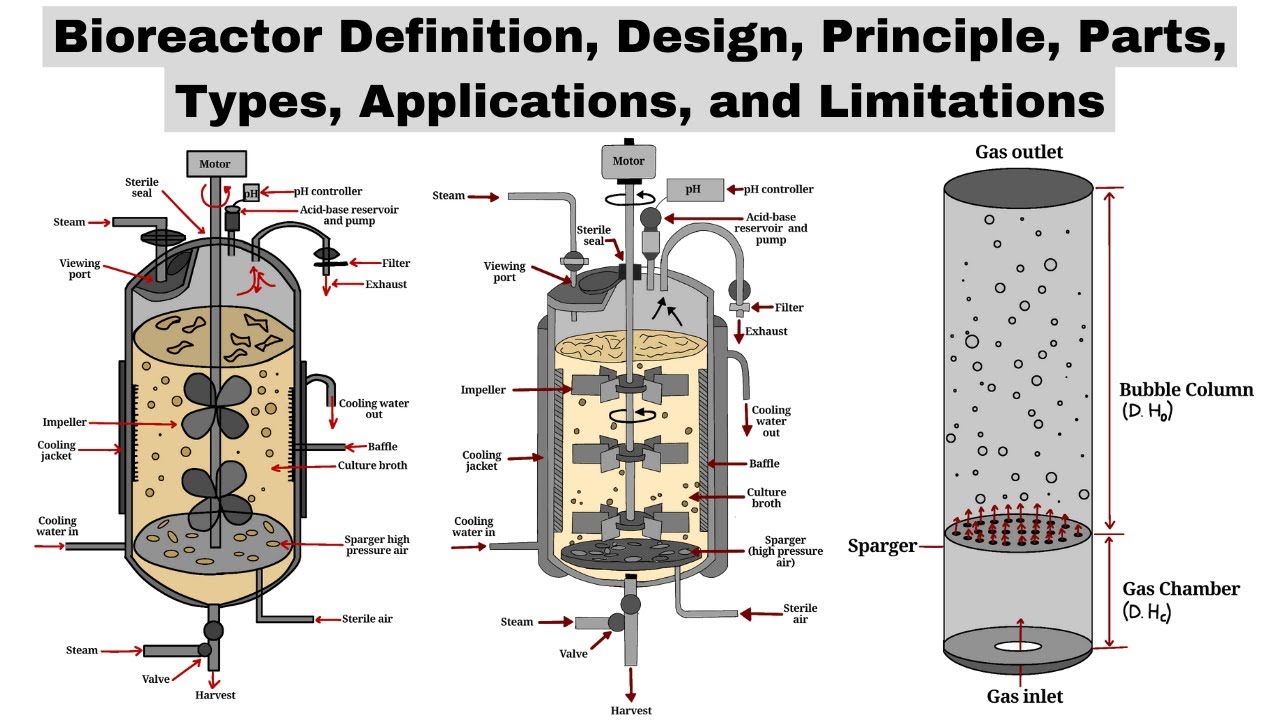

Bioreactors | Design, Principle, Parts, Types, Applications, & Limitations | Biotechnology Courses

5.0 / 5 (0 votes)