How It's Made: Flatware

Summary

TLDRThe process of creating stainless steel flatware is an intricate journey that begins with a thick coil of wire. Knives are forged, with special attention to the bolster and serrated edges for durability. The handles, crafted from high-nickel stainless steel, are meticulously assembled using welding and soldering techniques. Spoons and forks are shaped, stamped, and pressed into form, while their profiles and designs are refined. Finally, the pieces are polished to a shine or plated in silver or gold for more formal sets. The entire process blends craftsmanship with automation, ensuring precision and quality in every piece.

Takeaways

- 😀 Humans have been making eating utensils since prehistoric times, with sterling silver flatware dominating for centuries before stainless steel became the preferred material in the 1950s.

- 😀 Stainless steel flatware is popular due to its durability, resistance to tarnishing, and long-lasting quality.

- 😀 The production process starts with a thick coil of wire, which is cut into blanks to form the base of flatware, including knives, forks, and spoons.

- 😀 For knives, the first step is shaping the bolster, the part that connects the blade to the handle, followed by forging and welding the tang that fits inside the handle.

- 😀 The blade is then progressively shaped and tapered using grinding wheels, with serrations added to the edge for cutting efficiency.

- 😀 Knife handles are made from stainless steel with a high nickel content, providing enhanced corrosion resistance and ease of shaping for intricate designs.

- 😀 The handle is formed by welding two halves together, then adding copper-based wire that melts and thoroughly fuses the two halves.

- 😀 After the handle is completed, liquid cement is added into the handle cavity, which is spun into place by centrifugal force to securely hold the blade.

- 😀 Spoons are shaped by first cutting stainless steel into brush-shaped pieces, then thinning the end into a rounded bowl with heavy rollers, followed by trimming and coining to form the final shape.

- 😀 Forks undergo similar shaping steps as spoons but include additional processes to form the tines, which are then bent and cut to the proper shape.

- 😀 The final step for all flatware is polishing, where cloth wheels and buffing compounds give the pieces a shiny, smooth finish, with some being plated in silver or gold for a more formal look.

Q & A

What is the primary reason stainless steel is preferred over sterling silver for flatware?

-Stainless steel is preferred because it is durable, resistant to tarnishing, and more affordable compared to sterling silver, making it ideal for everyday use.

How is the bolster of a knife formed in the manufacturing process?

-The bolster of the knife is formed by a heading machine that cuts the coil of wire into blank pieces and shapes the head at one end. This bolster will later connect the blade to the knife handle.

Why is the tang important in the creation of a knife?

-The tang is the part of the knife that fits into the handle. It is crucial because it provides strength and stability to the knife, ensuring the handle is securely attached to the blade.

What role does the furnace play in knife production?

-The furnace softens the stainless steel, allowing it to be shaped in the forging press. This step is essential to make the metal malleable for further shaping.

Why is high-nickel stainless steel used for knife handles?

-High-nickel stainless steel is used for knife handles because it offers greater corrosion resistance and is easier to form, which is important for creating intricate designs.

How is the handle of a knife created?

-The handle begins as two halves that are spot-welded together. Then, a copper-based wire is used to solder the halves, followed by grinding to smooth the seam and ensure a solid bond.

What is the purpose of the carousel in the handle manufacturing process?

-The carousel is used to spin 50 knife handles at once, applying centrifugal force to spread liquid cement into the cavities of the handles, which is then cured to hold the handle structure together.

How is the spoon bowl formed during production?

-The spoon bowl is formed by heavy rollers that stretch and thin the metal, followed by a coining press that punches a pattern into the handle and forms the rounded bowl shape.

What process is used to create the tines of a fork?

-The tines of a fork are formed in two stages using a press. A support bar holds the tines in place, while a coining press creates a slight bend. Afterward, the support bar is removed, and the forks are stacked.

What happens during the buffing stage of flatware production?

-In the buffing stage, cloth wheels polish the surface of the flatware using a liquid buffing compound, resulting in a shiny, smooth finish for the stainless steel.

How is the flatware prepared for packaging?

-Casual flatware is packaged after the buffing process. More formal flatware, however, is further dressed up with full or partial plating in silver or gold before being packaged.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Golf Clubs | How It's Made

Why Doesn’t Stainless Steel Rust?

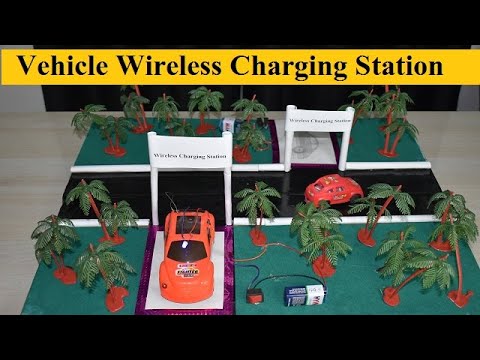

Wireless Electric Vehicle Charging System ,wireless power transmission Project #technology #science

GCSE Physics - Generator Effect / Electromagnetic Induction #81

Snapped coil spring replacement HYUNDAI TUCSON #hyundai #tucson #snappedcoilspring

Black Oxide: The Simple and Powerful Way to Transform Your Hardware

5.0 / 5 (0 votes)