Sheet Metal Oprations || Part 1 || Metal Forming Processes

Summary

TLDRThis video script delves into sheet metal processing, outlining various methods used in metalworking. It explains fundamental processes like cutting and forming, which are crucial for shaping metal into desired products. The script discusses different forming techniques such as bending, roll forming, spinning, deep drawing, and stretch forming, each serving to alter the metal's shape without cutting. It also touches on operations like shearing, blanking, notching, perforating, slitting, and lancing, essential for preparing metal sheets for further processing. The script aims to educate viewers on the intricacies of sheet metal processing, highlighting the transformation of flat metal sheets into complex shapes for various applications.

Takeaways

- 🔧 Sheet metal processing involves various methods to form metal into thin and flat pieces, which are fundamental in metalworking.

- ✂️ Cutting or shearing is a process where metal is cut, and actual metal is removed from the sheet, unlike forming processes where no material is removed.

- 🛠 Forming is a process that changes the shape of the metal without cutting, such as bending, rolling, spinning, deep drawing, and stretch forming.

- 📏 Bending is a metal forming process where a sheet metal is folded to create an angle, and it can be done using methods like V-bending or air bending.

- 🔩 Roll forming is a continuous process where sheets are passed through a series of rolls to form long strips or profiles, like pipes, without any cutting involved.

- 🔄 Spinning is a forming process where a disc of metal is rotated and shaped by applying pressure, changing its form and style.

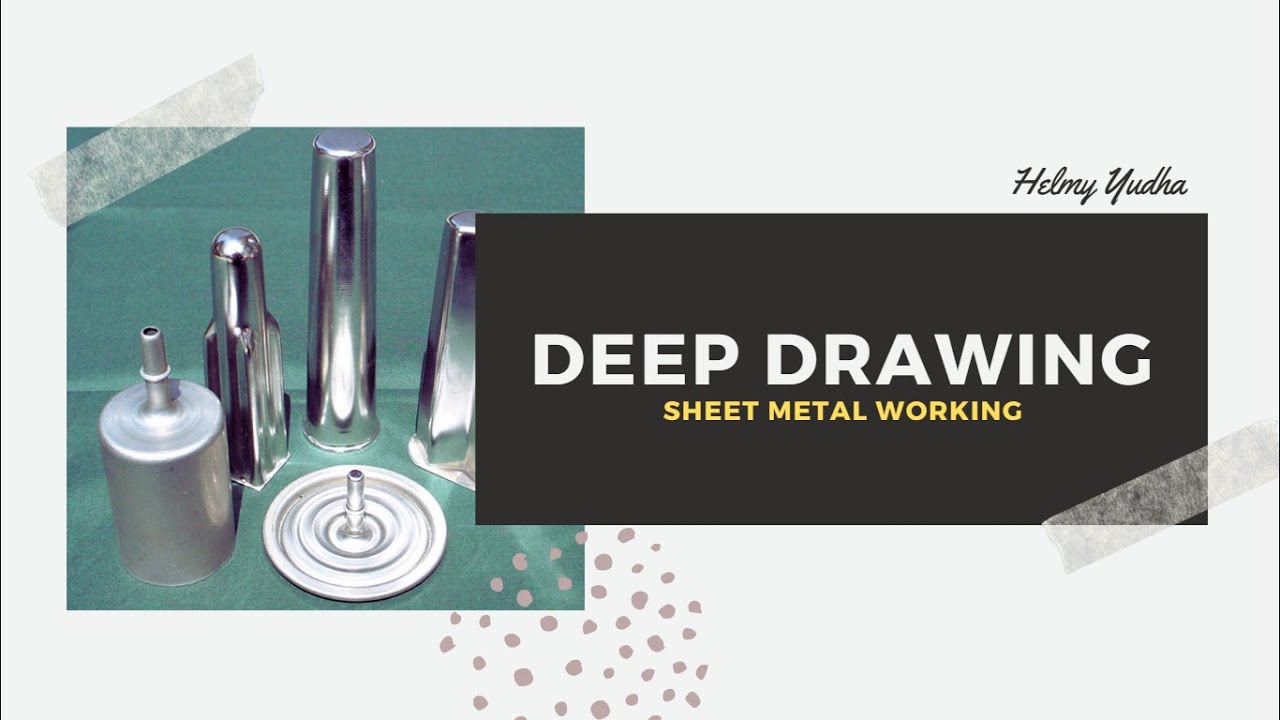

- 💧 Deep drawing is similar to bending but goes to an extra level by forming the metal into a deep three-dimensional shape, like a cup or container, from a flat sheet.

- 🔄 Stretch forming is a process that combines bending and stretching the metal to create a shape, often used for complex curves and contours.

- 🔩 The script emphasizes the importance of understanding the difference between cutting and forming processes in sheet metal processing.

- 👷♂️ The video script is educational, aiming to teach viewers about various sheet metal processing techniques used in metalworking industries.

Q & A

What is sheet metal processing?

-Sheet metal processing involves forming metal into thin and flat pieces. It is a fundamental form used in metalworking to create various shapes and products.

What are the two primary categories of sheet metal operations?

-The two primary categories are cutting (like shearing) and forming (like bending). Cutting involves removing material, while forming changes the shape without cutting.

What are the main processes involved in sheet metal forming?

-The main forming processes include bending, roll forming, spinning, deep drawing, and stretch forming.

What is the difference between cutting and forming in sheet metal processing?

-Cutting involves the removal of metal from a sheet to achieve the desired shape, whereas forming involves changing the shape of the metal without removing any material.

What is bending in sheet metal processing?

-Bending is a process in which a force is applied to a sheet of metal to bend it at an angle, changing its shape without cutting.

What are the two types of bending mentioned?

-The two types of bending are V-bending, where the sheet is bent into a V-shape using a die, and air bending, which allows for more flexibility in the bending angle.

What is roll forming?

-Roll forming is a continuous bending operation in which a long strip of metal is passed through rolls to form the desired shape, commonly used to make pipes and other round objects.

How does spinning work in sheet metal processing?

-Spinning involves rotating a sheet of metal and applying pressure to change its shape gradually, often used for producing rounded or conical shapes.

What is deep drawing?

-Deep drawing is a process similar to bending, but it involves stretching the metal deeper to form items like cups. The metal is pressed into a die to create a deep, cylindrical shape.

What distinguishes stretch forming from other forming processes?

-In stretch forming, the metal is not only bent but also stretched. This process applies additional force to pull the metal, forming more complex shapes.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

DEEP DRAWING IN SHEET METAL WORKING || Pembentukan Logam Lembaran

Zaman Logam - Masa Perundagian (Zaman Tembaga, Perunggu, dan Besi) #video #sejarah

Telecurso 2000 Processos de Fabricação 12 A união faz a solda

Powder Metallurgy Touches Your Life, Part 2

Deformation Processes 1 Fundamental

Indonesia Raja Nikel Dunia, Beginilah Proses Singkat Pengolahan Nikel

5.0 / 5 (0 votes)