PLC OMRON CP1E | CARA PASANG INPUT OUTPUT

Summary

TLDRThis video tutorial from the 'jago listrik' channel focuses on the installation of input and output components for the Omron CP1E PLC. It explains that inputs are typically on top and outputs below, with the unique requirement for a DC 24-volt supply instead of the usual AC. The presenter demonstrates how to convert 220-volt AC from the power supply to the necessary DC voltage using a power supply unit. The video also covers wiring the input and output components, highlighting the connection of a common (COM) terminal for all inputs and separate COM terminals for different output ranges, ensuring viewers understand the setup for the Omron CP1E PLC.

Takeaways

- 🔌 The video discusses the installation of input and output components on an Omron CP1E PLC.

- 📌 Inputs are typically placed above and outputs below on the PLC, with the supply input voltage being a key consideration.

- ⚡ The Omron CP1E uses DC voltage for inputs, specifically 24 volts DC, differing from the common AC voltage used in other PLCs.

- 🔄 A power supply unit is necessary to convert 220 Volt AC from the mains to the required 24 Volt DC for the PLC.

- 🔗 The wiring of the power supply involves connecting the LN (Line) and ground to the AC source and the output to the PLC's positive and negative terminals.

- 🔩 The input components, such as push buttons, are connected to the DC power supply's positive voltage, while the common (COM) terminal is connected to the negative voltage.

- 🔑 A single COM terminal is used for all inputs, simplifying the wiring process for inputs.

- 💡 The video provides a practical example of connecting a normally closed (NC) push button to an input address and an output to a specific address.

- 🔑 For outputs, each set of outputs has its own COM terminal, which is different from the input's single COM terminal setup.

- 🛠️ The video explains how to wire outputs to the corresponding output addresses on the PLC, with each output having its own designated address.

- ❓ The presenter invites viewers to ask questions in the comments if they need further clarification.

Q & A

What is the main topic discussed in the video?

-The main topic discussed in the video is the installation of input and output components on an Omron CP1E PLC.

What is the difference between the input voltage for Omron CP1E PLC and other PLCs?

-The Omron CP1E PLC uses a DC voltage of 24 volts for its inputs, unlike other PLCs which typically use AC voltage for inputs.

Why is it necessary to convert AC voltage to DC for the Omron CP1E PLC?

-It is necessary to convert AC voltage to DC for the Omron CP1E PLC because its input components require a DC voltage of 24 volts.

What is the role of a power supply in the setup described in the video?

-The power supply is used to convert the AC voltage from the mains (220 Volt AC) to the required DC voltage (24 Volt DC) for the PLC's input components.

How are the input components connected to the Omron CP1E PLC?

-The input components are connected to the Omron CP1E PLC by linking the common (COM) terminal to the negative polarity of the DC power supply and connecting the input devices to the positive DC voltage.

What is the purpose of the COM terminal in the context of the video?

-The COM terminal is used as a common connection point for all input addresses from 00 to 11, allowing a single COM connection for all inputs.

How does the wiring for input components differ from output components on the Omron CP1E PLC?

-For input components, there is only one COM for all input ports, whereas for output components, there are multiple COMs (1, 2, 3, and 4), each serving different ranges of output addresses.

What is the significance of the thick white line mentioned in the video?

-The thick white line signifies the limit for each output COM, indicating that each output has its own dedicated COM terminal and should not be mixed with others.

How are the output components connected to the Omron CP1E PLC?

-The output components are connected by linking the respective COM terminal to the negative polarity of the DC power supply and connecting the load or device to the corresponding output port.

What is the address format for outputs on the Omron CP1E PLC as described in the video?

-The address format for outputs on the Omron CP1E PLC is 'Q' followed by the slot number and the channel number, such as Q100.00 for output 00.

What does the video suggest for viewers who are not clear about the content?

-The video suggests that viewers who are not clear about the content can leave a comment below for further clarification.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

PART 1 PEMBUATAN DIAGRAM LADDER CX PROGRAMMER "Kendali manual motor on berurutan"

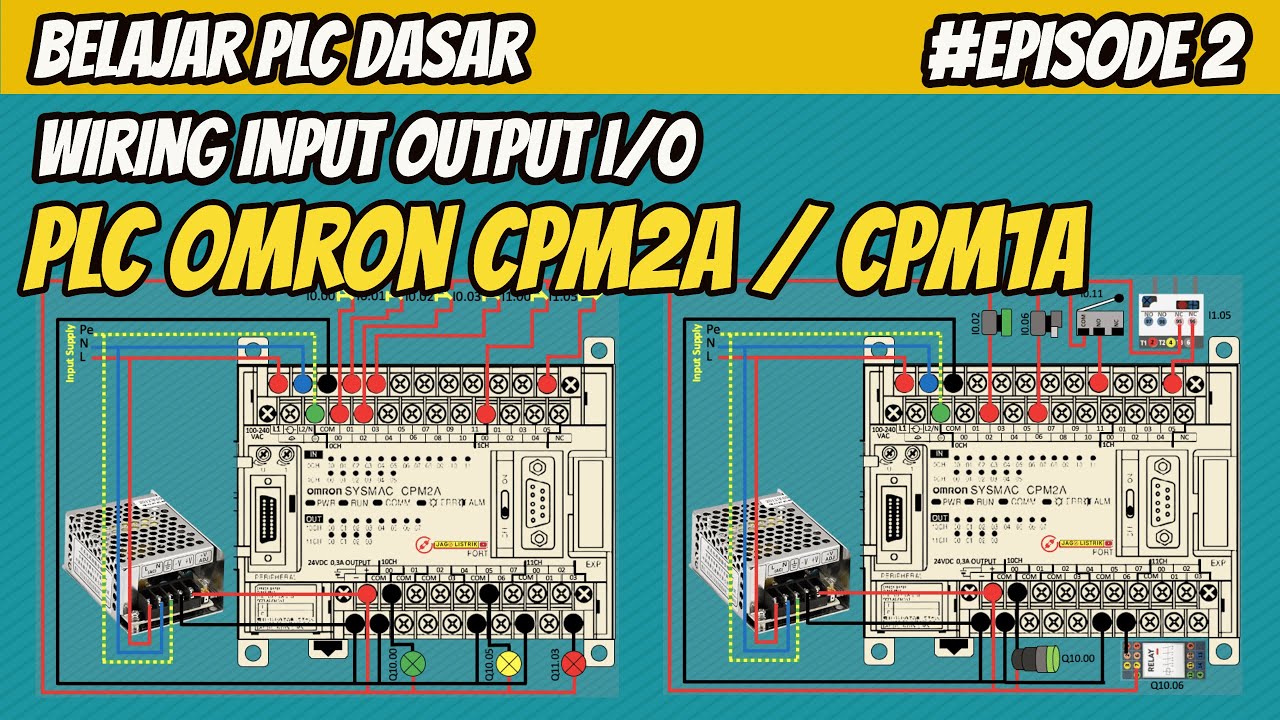

BELAJAR WIRING INPUT OUTPUT PLC OMRON | OMRON CPM2A CPM1A

WIRING CP1E Panduan Praktis Basic Wiring PLC OMRON CP1E untuk Pemula!

Belajar Proximity Sensor & Mengkoneksikannya Ke PLC Omron

PLC OMRON #1 - Memahami Hardware Secara Detail dan Memahami Terminal I/O PLC OMRON CP1L

What is a PLC? (90 sec)

5.0 / 5 (0 votes)