How Mechanical Seals Work - stuffing box - packing

Summary

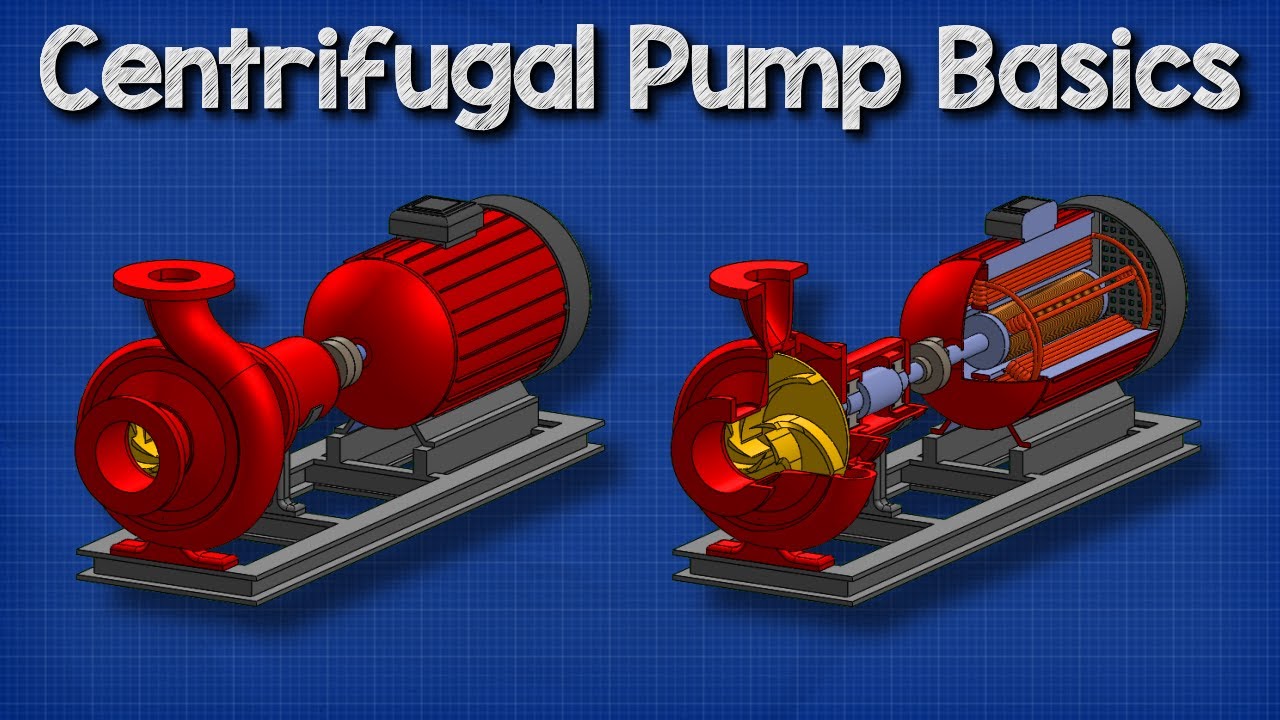

TLDRThe video script explains the function and importance of mechanical seals in hydraulic machinery, such as centrifugal pumps. Mechanical seals, offered by Jaws for over a decade, replace traditional stuffing boxes to prevent fluid leakage and reduce friction. They consist of a stationary and rotating part, creating a fluid film for lubrication and preventing direct contact, thus enhancing efficiency and reducing maintenance. Jaws Company provides a variety of mechanical seals from leading manufacturers, emphasizing their role in modernizing the industry.

Takeaways

- 🛠️ The mechanical seal is a device designed to isolate two environments, preventing fluid leakage between them.

- 🏭 Jaws has been a leading provider of mechanical seals for over a decade, offering a wide range of options from top manufacturers.

- 🔧 Mechanical seals are crucial in hydraulic machinery, such as centrifugal pumps, where they prevent fluid leakage and ensure efficient operation.

- 📍 The seal is positioned on the back plate to contain fluids within the pump, acting as a barrier between the pump's interior and the external environment.

- 🔄 The mechanical seal must withstand pressure and resist friction caused by the rotating shaft, which is a key function in its operation.

- 🔧 Traditional stuffing boxes, made of twisted wire rope, were used to seal around the shaft but have several drawbacks including wear, maintenance, and energy consumption.

- 🚀 Mechanical seals are increasingly replacing stuffing boxes due to their efficiency and ability to overcome the disadvantages of the older method.

- 🔄 A common mechanical seal features three sealing points, with the stationary part attached to the pump's back plate and the rotating part attached to the shaft.

- 💡 The moving element in the rotating part of the seal is pressed by a spring, ensuring contact with the stationary part and creating a sealing point.

- 🔧 The seal's operation involves the rotating part following the shaft's movements, compensating for misalignments and thermal expansions.

- 🛡️ The seal's faces, which are in contact, are made with extreme precision and smoothness to minimize friction and are lubricated by the fluid being pumped or an external source.

- 🌐 The mechanical seal can isolate the internal pump environment from the external environment, even with a rotating shaft, maintaining a sealed system.

Q & A

What is a mechanical seal?

-A mechanical seal is a device capable of isolating two environments, typically used in hydraulic machinery to prevent fluid leakage between a rotating shaft and a stationary housing.

What is the purpose of a mechanical seal in a centrifugal pump?

-In a centrifugal pump, the mechanical seal is placed on the back plate to contain the fluids inside the pump, preventing them from leaking through the space between the back plate and the shaft.

What are the components of a typical mechanical seal?

-A typical mechanical seal consists of a stationary part fixed to the pump's back plate, a rotating part fixed to the shaft, and a sealing element between them that creates a seal.

How does the mechanical seal handle pressure and friction?

-The mechanical seal is designed to hold pressure during pumping and resist the friction caused by the shaft's rotation, utilizing a fluid film for lubrication and preventing direct contact between the sealing surfaces.

What are the disadvantages of using stuffing boxes compared to mechanical seals?

-Stuffing boxes require constant maintenance, wear out quickly, consume large amounts of water for cooling, and waste energy from the motor due to friction. Mechanical seals are more efficient and address these issues.

What is the role of the sealing basket in a mechanical seal?

-The sealing basket is part of the stationary component of the mechanical seal, positioned between the stationary part and the rotating part to help maintain the seal.

How does the rotating part of a mechanical seal interact with the stationary part?

-The rotating part of a mechanical seal rotates integral with the shaft and is pressed against the stationary part by a spring, creating a sealing point and following the shaft's movements to accommodate misalignments and thermal expansions.

What is the purpose of the fluid film in the mechanical seal?

-The fluid film serves as a lubricant between the sealing surfaces, reducing friction and preventing direct contact, which can be formed from the fluid being pumped or introduced from an external source.

What are the benefits of using mechanical seals over older sealing methods?

-Mechanical seals offer improved efficiency, reduced maintenance, lower energy consumption, and better containment of fluids, making them a more modern and effective sealing solution.

How can mechanical seals isolate the internal pump room from the external environment?

-Mechanical seals can isolate the internal pump room by creating a barrier that prevents fluid leakage and interaction between the internal and external environments, despite the presence of a rotating shaft.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Centrifugal Pump Basics I Definition I Working I Velocity Triangle I Work Done I Head I Efficiency

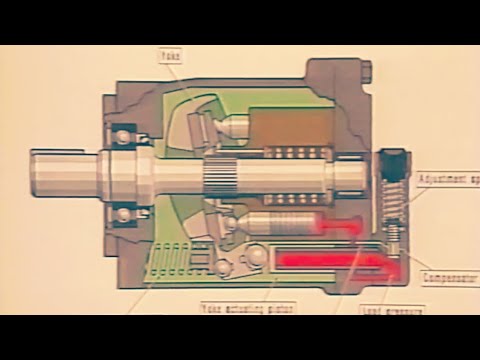

Hydraulic Training Series - Chapter 2 - Hydraulic Pumps

#Centrifugical pumps troubleshooting

Types of Pumps | All in One Guide to Industrial Pump Types

Tertarik tentang Mechanical ?? Yuk pelajari Dasar-Dasar Mechanical

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

5.0 / 5 (0 votes)