What Is Modeling and Simulation?

Summary

TLDRAerospace engineers use modeling and simulation to evaluate designs and test systems in a virtual environment, avoiding costly and time-consuming physical prototypes. These digital tools help diagnose problems, simulate extreme events, and predict system responses using physical, process, and mathematical models. Simulations, including live, virtual, and constructive types, allow engineers to test scenarios like flight or natural disasters before real-world application. By leveraging mathematical models, virtual simulations, and complex data, engineers can refine products and solve global challenges efficiently. The video also introduces Simulink as a tool for beginners to start exploring modeling and simulation.

Takeaways

- 😀 Engineers use modeling and simulation to test designs before building physical prototypes.

- 😀 Building physical prototypes is time-consuming and expensive, making digital models essential.

- 😀 Testing with real prototypes can be risky and often exceeds budget constraints.

- 😀 We can't predict every possible outcome, but digital tools allow testing under extreme conditions.

- 😀 Models can be categorized into physical models, process models, and mathematical models.

- 😀 Physical models are scaled representations of real systems, like model trains or cars.

- 😀 Process models track workflows, such as supply chains or financial approval processes.

- 😀 Mathematical models predict system behavior, like how fast an apple will fall or how hard it will hit you.

- 😀 Simulations come in three types: live simulations, virtual simulations, and constructive simulations.

- 😀 Live simulations involve real people acting out scenarios, like business students role-playing as CEOs.

- 😀 Virtual simulations use computers to model scenarios, like a digital twin of a robot arm.

- 😀 Constructive simulations combine live and virtual simulations, such as flight simulators for pilots.

- 😀 Engineers test designs in a digital environment (like Simulink) before actual implementation in real-world situations.

Q & A

Why do engineers rely on modeling and simulation instead of building physical prototypes?

-Engineers use modeling and simulation because physical prototypes are time-consuming, expensive, and testing them for every possible outcome is often impractical. Digital models allow for quicker, cheaper, and more flexible testing.

What are some challenges associated with building and testing physical prototypes?

-Building physical prototypes requires a lot of materials, time, and labor. Additionally, testing these prototypes can be expensive, especially when they involve million-dollar designs that could break or fail during testing.

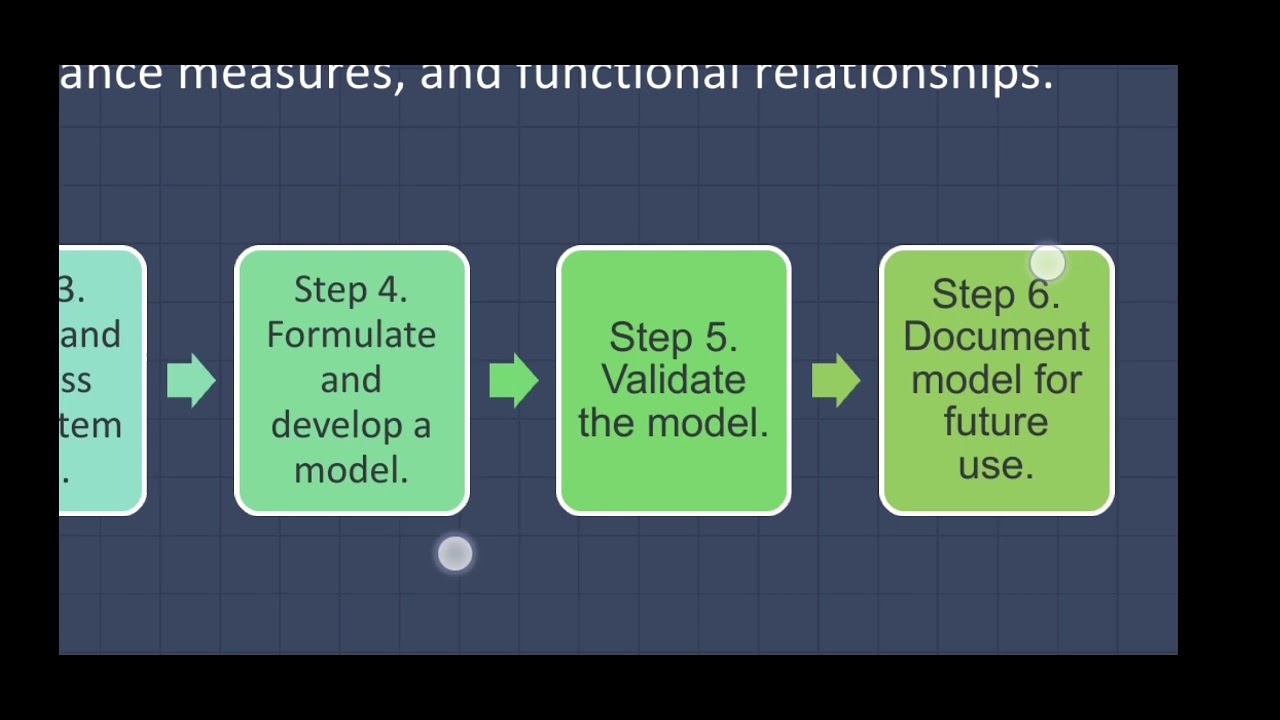

What are the three categories of models mentioned in the script?

-The three categories of models are physical models (scaled representations of real systems), process models (like flowcharts or supply chains), and mathematical models (equations predicting system responses).

What is the purpose of mathematical models, and how are they useful?

-Mathematical models are used to predict how systems will respond. They provide insights into future behaviors, such as predicting how fast an apple will fall or how hard it will hit the ground.

What is the difference between live, virtual, and constructive simulations?

-Live simulations involve people roleplaying scenarios. Virtual simulations use computers to model scenarios (like digital twins). Constructive simulations combine both, with examples like flight simulators used for pilot training.

How does simulation help engineers design products before physical testing?

-Simulation allows engineers to test and tweak their designs virtually, under extreme conditions, before committing to physical prototypes. This saves time and money while ensuring that the design is tested against all possible outcomes.

What is a 'digital twin' in the context of simulation?

-A digital twin is a virtual model of a real-world object or system. In the example given, a digital twin of a robot arm is used to test how components will work together before the physical assembly takes place.

Why is testing a new wind turbine design in a real hurricane impractical?

-Testing a wind turbine in a real hurricane is impractical due to the extreme and unpredictable nature of such events. Simulation allows engineers to replicate these conditions digitally, ensuring the turbine design can withstand such forces without waiting for a natural disaster.

What role do mathematical models play in engineering simulations?

-Mathematical models are integral to engineering simulations, as they provide the equations that predict how different components or systems will behave under specific conditions, enabling accurate and detailed testing before physical trials.

How do digital tools like Simulink assist engineers in solving complex problems?

-Digital tools like Simulink allow engineers to create simulations that integrate mathematical models, real-time data, and system behaviors to design and test products in a virtual environment before actual production.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahora5.0 / 5 (0 votes)