Scales of Production

Summary

TLDRThis video explains the four scales of production: continuous, mass, batch, and one-off production. It highlights the key characteristics of each, such as unit cost, equipment, labor type, initial investment, and production efficiency. Continuous production is for high-volume, standardized products like soft drink bottles, while mass production focuses on high-volume, low-cost items like biro pens. Batch production is more flexible, ideal for products with seasonal demand, and one-off production is for bespoke, high-cost items requiring skilled labor. The video emphasizes the trade-offs between cost, efficiency, and labor involved in each production method.

Takeaways

- 😀 Continuous production is used for mass-produced, standardized products that meet everyday market needs, such as soft drinks and energy. It runs 24/7 with highly automated machinery.

- 😀 The unit cost for continuous production is very low, as it involves high automation and specialized tools like blow molding machines.

- 😀 The initial investment for continuous production machinery is very high, but production efficiency is extremely high due to automation, allowing for millions of products to be manufactured quickly.

- 😀 In continuous production, labor tends to be unskilled, overseeing machinery with minimal training and performing basic maintenance, resulting in low wages.

- 😀 Mass production, similar to continuous production, involves the production of high-volume products with automated processes, such as biro pens, with high initial investment in machinery.

- 😀 The unit cost of mass production is low, but initial investment in machinery is high. It relies on specialized equipment and unskilled labor, similar to continuous production.

- 😀 Batch production is used for products manufactured in predetermined batches, offering flexibility with machinery and workforce to adapt to different product requirements.

- 😀 In batch production, unit costs are higher than mass production, but it offers more flexibility due to modular or flexible manufacturing systems that can quickly change between product types.

- 😀 Batch production typically involves semi-skilled labor, who have some training on machinery and tool changes, resulting in slightly higher wages than unskilled labor.

- 😀 One-off or bespoke production involves creating individual, customized products like tailored suits or handmade furniture. This method requires high skill levels, specialized tools, and a lot of time, making it a high-cost method of production.

Q & A

What are the four scales of production discussed in the video?

-The four scales of production discussed are continuous production, mass production, batch production, and one-off (bespoke) production.

How does continuous production differ from other production methods?

-Continuous production is used for standardized mass-produced products that are made around the clock, without significant changes. It uses highly automated machinery and produces large volumes of products at low unit costs.

What types of products are typically made using continuous production?

-Products such as soft drink bottles, cans, energy supplies like electricity, and mass market products such as egg boxes and wine bottles are commonly produced using continuous production.

What is the unit cost of items produced through continuous production?

-The unit cost of items produced through continuous production is very low due to the high volume of products made and the efficiency of the automated systems.

What role do workers play in continuous production?

-Workers in continuous production are typically unskilled laborers who oversee machinery, perform quality control, and conduct minor maintenance tasks. Their wages are relatively low.

How does mass production compare to continuous production?

-Mass production is similar to continuous production but involves high-volume production of standardized products in a factory setting, often with automated machinery. However, it typically focuses on a specific product for a large market, like biros or pens.

What is the key characteristic of batch production?

-Batch production involves manufacturing products in predetermined batches, which allows flexibility in production. It can adapt to produce different products after changing tools or machinery, making it less rigid than continuous production.

What types of products are suited for batch production?

-Batch production is ideal for products that are manufactured in high volumes but require periodic redesigns or production changes. Examples include flat-pack furniture like IKEA products or seasonal goods.

How does the labor type in batch production differ from other production scales?

-Batch production typically requires semi-skilled workers who are trained to handle flexible machinery, change tooling, and perform some maintenance. They earn higher wages than unskilled laborers in mass or continuous production.

Why is one-off (bespoke) production considered high-cost?

-One-off production is high-cost due to the time and specialized skill required to create unique products, such as custom furniture or wedding dresses. It also requires specialized tools and a high level of craftsmanship.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Job, batch, flow and mass customization methods - Business Management - Teacher RK

What is Production? Types of Production, Factors of Production

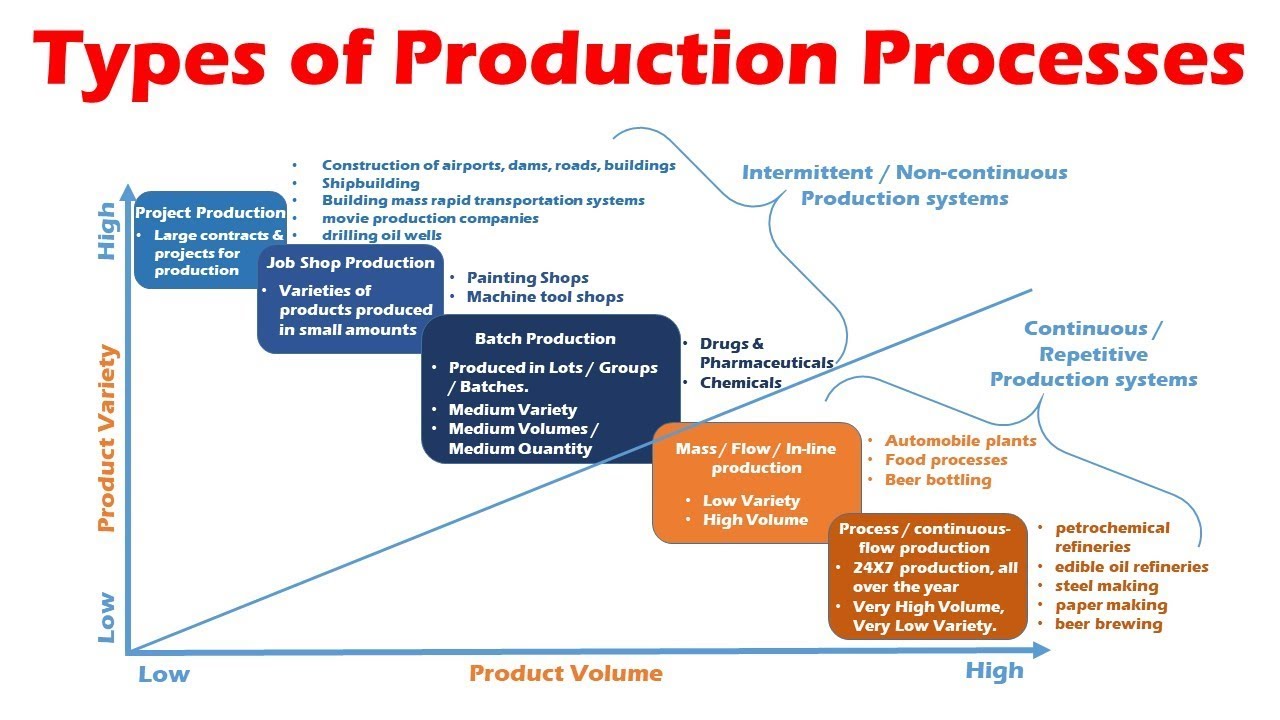

Types of Production Systems (Process, Mass, Flow, Batch, Job Shop & Project Production Systems)

Exploring Production Methods: Job, Batch, and Flow Production Explained | ThinkIGCSE.com

Understanding Production Volume & Plant Layout: Job, Batch, and Mass Production Explained!

Process Selection - A Review of Continuous Flow, Assembly Line, Batch Flow and Job Shop

5.0 / 5 (0 votes)