5 Prinsip SMK3: Perencanaan K3

Summary

TLDRThis video discusses the second principle of SMK3 (Occupational Health and Safety Management System), focusing on planning. It emphasizes the importance of documenting procedures, such as hazard identification, risk assessment, and risk control (HIRAC), within an organization. The video details the requirements for creating documented procedures, managing risks, and setting safety objectives and programs. It highlights the need for clear communication and proper distribution of procedures, whether through emails or cloud systems. The video stresses that safety planning should be incorporated into every workplace, particularly in projects or factories, to effectively measure and implement safety standards.

Takeaways

- 😀 The second principle of SMK3 focuses on planning for health and safety in the workplace.

- 😀 Companies must ensure their safety policies include efforts to prevent accidents and occupational diseases, compliance with regulations, and continuous improvement.

- 😀 SMK3 requires companies to create documented information, including a list of at least 20 mandatory procedures, as outlined in PP 50 2012.

- 😀 The creation and management of documented procedures should involve at least two or three people to ensure validity and avoid conflicts of interest.

- 😀 When distributing procedures digitally, ensure proper document control through email acknowledgment or cloud-based systems with restricted access.

- 😀 SMK3 implementation should include a thorough Hazard Identification, Risk Assessment, and Risk Control (HIRAC) process, involving workers familiar with risks in their work environment.

- 😀 The risk control hierarchy in SMK3 includes elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE).

- 😀 HIRAC must be communicated and displayed at relevant work locations to ensure awareness among workers, such as in production areas.

- 😀 The company should also create a safety program or HSE plan, which includes specific objectives, targets, and action plans following the SMART criteria (Specific, Measurable, Achievable, Reasonable, Time-Bound).

- 😀 The HSE plan not only addresses safety programs but also includes policies, procedures, tools, and equipment used in the safety process.

- 😀 Regular evaluation of safety programs and HSE plans is necessary to track progress and assess performance, ensuring continual improvement.

Q & A

What are the three key elements that must be included in a K3 policy according to the script?

-The three key elements in a K3 policy are: 1) Efforts to prevent workplace accidents and work-related diseases, 2) Compliance with regulations, and 3) Continuous improvement.

What does 'perencanaan K3' or K3 planning involve according to the video?

-K3 planning involves creating documented procedures, identifying hazards, assessing and controlling risks, and setting clear K3 objectives, targets, and programs.

How many procedures must a company create as part of K3 planning, according to the script?

-A company must create approximately 20 documented procedures as part of their K3 planning, as outlined in PP 50 2012, Attachment 2.

What are the four levels of document control mentioned in the video?

-The four levels of document control mentioned are: 1) Manual, 2) Procedure, 3) Work Instruction, and 4) Form or evidence of work.

Why is it necessary for at least two or three people to be involved in creating and approving documents?

-Involving multiple people ensures that the process is ethical and the results are valid. It prevents a situation where one person controls all aspects of creation, correction, and validation.

What is the recommended method for distributing documents digitally according to the script?

-Documents should be distributed digitally via email or a cloud system. If email is used, recipients must confirm receipt to ensure proper documentation. Access to cloud systems should be restricted to prevent unauthorized downloading or printing.

What does the script say about Hazard Identification, Risk Assessment, and Risk Control (HIRAK)?

-HIRAK involves identifying hazards, assessing risks based on activity and probability, and implementing risk control measures, following a hierarchy from elimination to protective equipment (APD).

Who is responsible for creating the HIRAK document in the workplace?

-HIRAK should be created by those working in the specific environment, as they are most familiar with the risks involved. It is not limited to safety experts.

What does the term 'TUSAS Pro' or OTP refer to in the context of K3 planning?

-TUSAS Pro, or OTP (Objective, Target, and Program), refers to setting specific, measurable, achievable, reasonable, and time-bound goals and programs for K3. These should be tracked and regularly evaluated.

What is an HSE plan or safety plan, and how does it relate to K3 planning?

-An HSE (Health, Safety, and Environment) plan or safety plan is a key part of K3 planning. It includes the K3 policy, procedures, work methods, tools used, personal protective equipment (PPE), and other safety measures specific to a project or factory environment.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

[NAWA] APA ITU SMK3?

Penerapan Sistem Manajemen K3 (sesuai PP No 50 tahun 2012) Part 1

RESUMO COMPLETO NOVA NR 1 - DISPOSIÇÕES GERAIS E GERENCIAMENTO DE RISCOS OCUPACIONAIS

Materi K3 dalam Pengelolaan Bisnis Ritel part 1

OHS Management Systems mini lecture

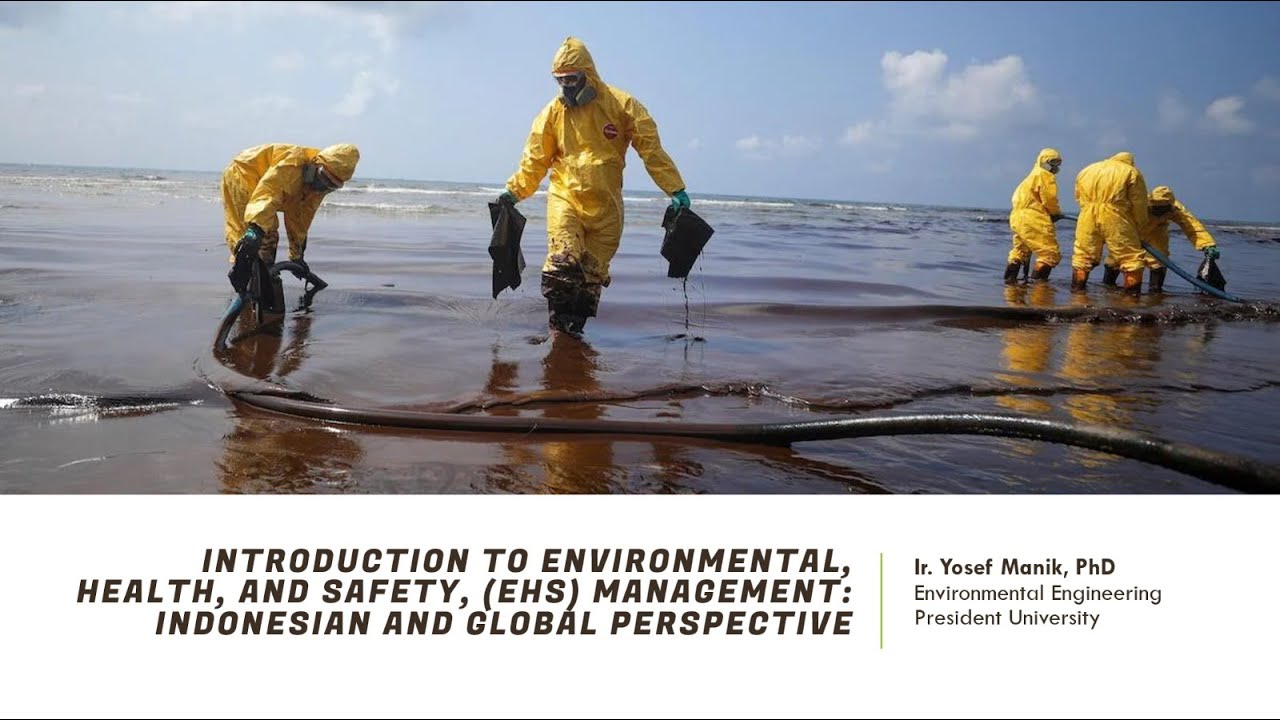

Introduction to Occupational Safety, Health, and Environmental (EHS)

5.0 / 5 (0 votes)