Praktikum Otomasi Industri 2_Latihan 3_Avicenna Ari Sumirat

Summary

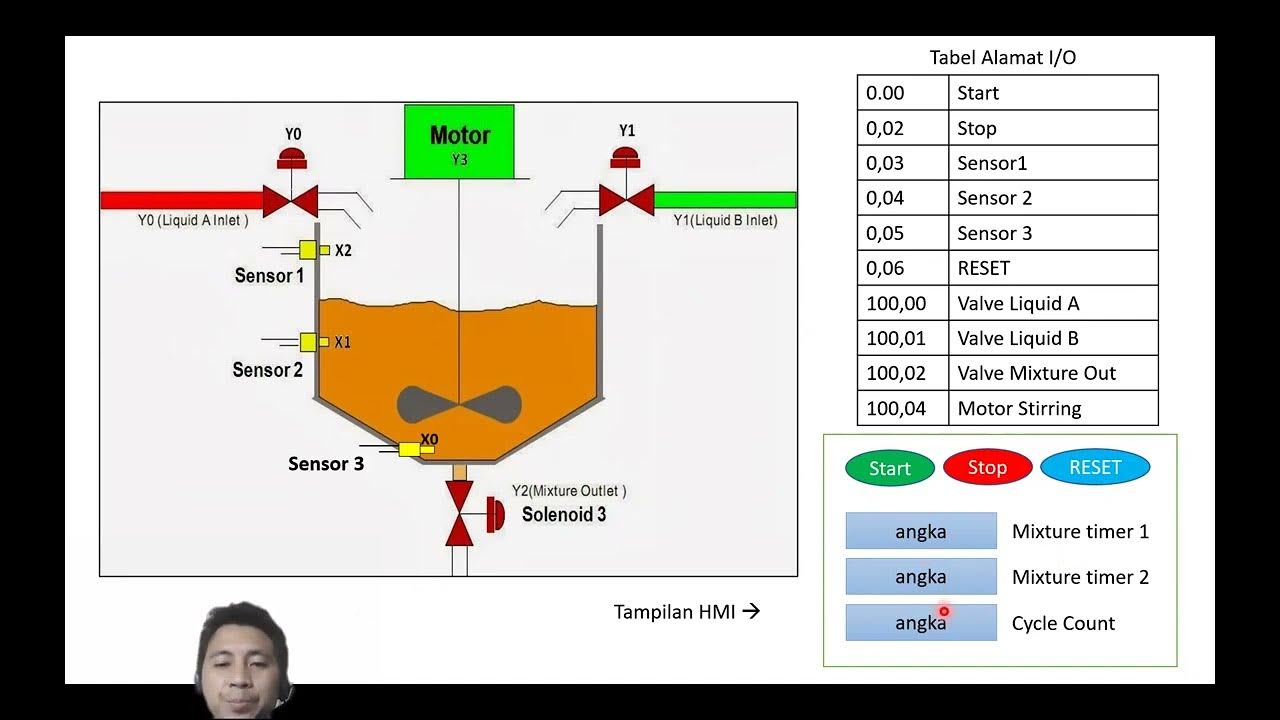

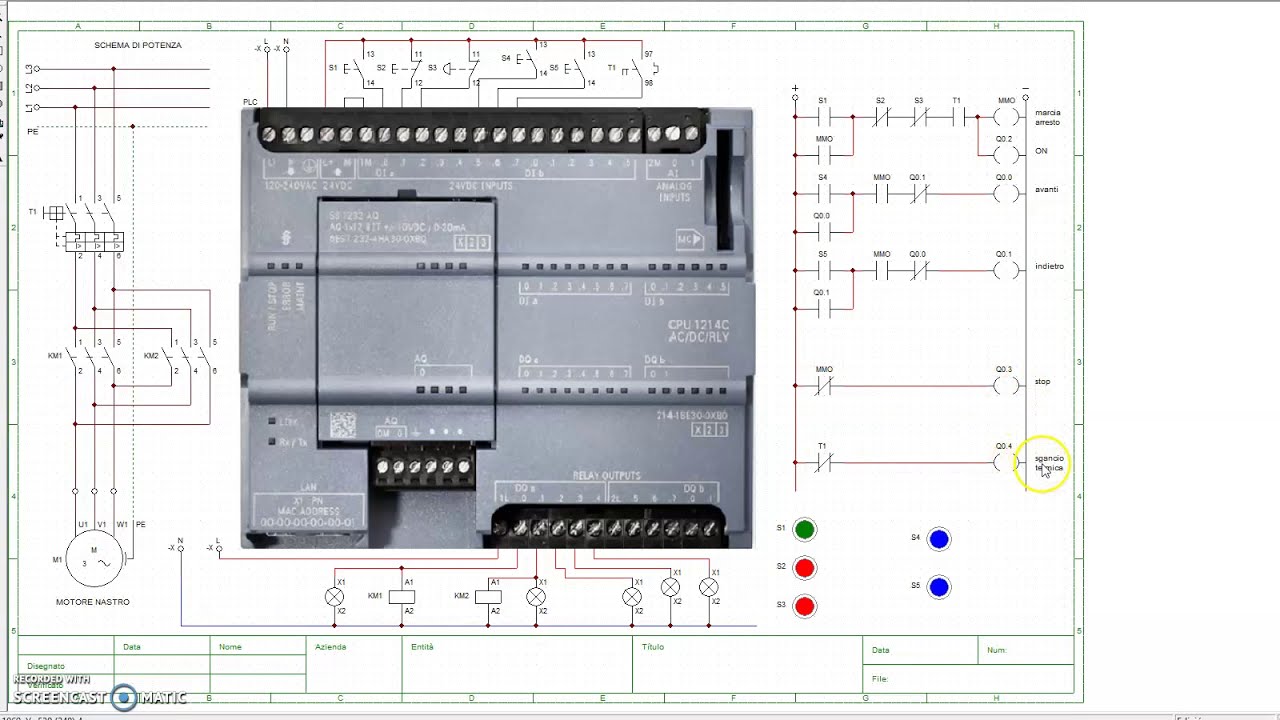

TLDRThe transcript presents a detailed overview of a PLC simulation and control system, focusing on an industrial automation project. It covers the simulation of solenoid and conveyor operations, emphasizing system controls via HMI and manual settings. The process is broken down into multiple steps, including sensor triggers, emergency protocols, and automated operations. Key features like auto/manual modes, emergency stops, and sequence debugging are discussed, along with a hands-on approach to troubleshooting and system resetting. The script highlights the integration of hardware and software for effective process control in an industrial setting.

Takeaways

- 😀 The presentation introduces a simulation and debugging exercise involving PLC programming, solenoids, and conveyors.

- 😀 The simulation panel allows for testing solenoid and conveyor systems without connecting to actual hardware, using PC-based software.

- 😀 The HMI (Human-Machine Interface) display enables direct uploading to the hardware, allowing for real-time monitoring and control.

- 😀 The system starts with solenoid A and B at their minimum positions, with sensor BK1 detecting the workpiece.

- 😀 Emergency stop functionality is integrated, halting the system and requiring a reset to continue operation.

- 😀 In auto mode, the system operates automatically, triggering sensors and executing a sequence of solenoid and conveyor movements.

- 😀 Manual mode allows for step-by-step control, useful for troubleshooting and testing individual components of the system.

- 😀 Push buttons PB1 and PB2 simulate the pressing of physical buttons, with PB2 acting as an alternate to simulate dual-button pressing.

- 😀 Timers and counters are used to manage the timing of operations, such as conveyor movement, and to trigger actions based on sensor feedback.

- 😀 The HMI panel includes sensors monitoring, machine modes, emergency buttons, and status displays, with some functions reserved for physical hardware rather than the HMI.

Q & A

What is the primary focus of the PLC simulation described in the script?

-The primary focus is on simulating the control of solenoids and a conveyor system through a PLC, using both auto and manual control modes. The simulation also involves debugging and HMI display for system monitoring.

What role does the simulation panel play in the system?

-The simulation panel simulates the operation of the solenoids and conveyor system, allowing for control via a PC without the need for physical hardware connections.

How is the HMI display used in the simulation?

-The HMI display is used to upload control and monitoring settings directly to the hardware, showing the status of different components like sensors and solenoids.

What happens when the emergency button is pressed?

-When the emergency button is pressed, it triggers an emergency stop, which requires the system to be reset manually before normal operation can continue.

What is the significance of the two push buttons (PB1 and PB2)?

-PB1 and PB2 are used to simulate a dual start button function. In the auto mode, both buttons must be pressed simultaneously to trigger the start of the system.

What does the system do when the start buttons are pressed in auto mode?

-When both start buttons are pressed in auto mode, the solenoid moves, and the conveyor system is activated, with sensors detecting the movement of the workpiece.

How does the manual mode differ from the auto mode in this simulation?

-In manual mode, each step of the cycle must be triggered manually by pressing buttons, allowing for troubleshooting and step-by-step control. In contrast, auto mode runs the cycle automatically once started.

What role does the simulation debug panel play in the process?

-The simulation debug panel simulates the triggering of sensors and limit switches to test and monitor the system's response to different conditions.

How does the system handle the detection of objects on the conveyor?

-The system uses sensors BK1 and BK2 to detect objects on the conveyor. When an object is detected by BK2, the system switches to the 'Run' state and continues the process until the object passes the sensor.

What is the function of the timer set at 2 seconds in the system?

-The 2-second timer is used to control the conveyor's operation. It triggers the return of the solenoid and resets the system's state after the workpiece has been processed.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Penjelasan Tugas Kelompok

PEMROGRAMAN PLC UNTUK OTOMASI INDUSTRI

mengenal plc dan contoh sederhana dengan zelio 3

Teleinversione motore trifase con PLC, schema potenza, pilotaggio e ladder simulazione

Praktik 9.1. PLC Pneumatic Instalasi dan Transfer program

What is Mechatronics? Let's Get to Know the Basic Components and How They Work! Simple Tutorial E...

5.0 / 5 (0 votes)