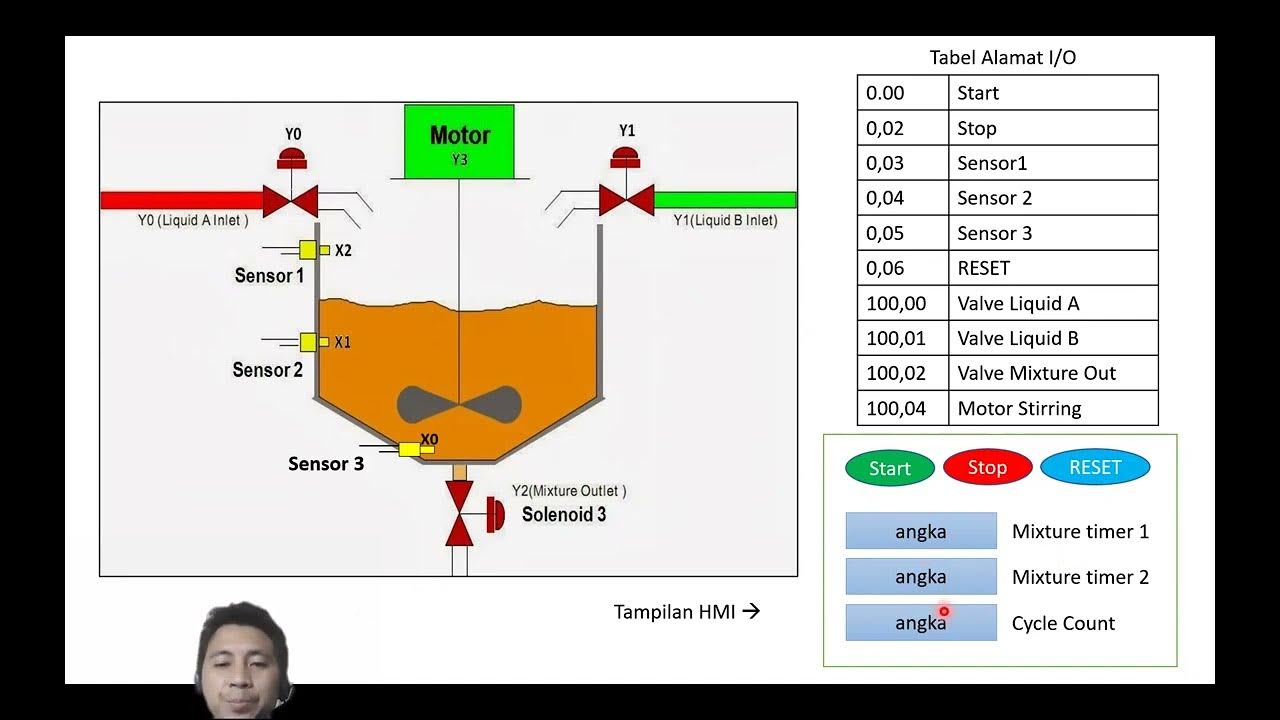

PEMROGRAMAN PLC UNTUK OTOMASI INDUSTRI

Summary

TLDRThis transcript provides an overview of PLC programming for industrial automation. It covers the basics of programming, including key instructions like SET, RESET, AND, OR, and others used to control inputs and outputs. It also delves into advanced topics like PID control, explaining the proportional, integral, and derivative feedback mechanisms used to optimize industrial processes. Additionally, the transcript highlights the benefits and challenges of using PID control, such as its accuracy and complexity. The content aims to equip students with the skills needed for industrial automation, producing competent workers ready to tackle various industry challenges.

Takeaways

- 😀 PLC programming is crucial for industrial automation, with students expected to design, develop, and apply PLC programs across various industrial automation scenarios.

- 😀 Students will learn the structure of PLC programming, advanced programming techniques, and the use of logic functions like timers and counters.

- 😀 Understanding and implementing PID control (Proportional, Integral, Derivative) techniques is a key learning outcome for optimizing industrial systems.

- 😀 The ultimate goal is to equip students with the skills to be competent in industrial automation and handle diverse work environments.

- 😀 Basic PLC instructions are essential for controlling inputs/outputs, making logic decisions, and performing other tasks like turning on/off outputs and counting pulses.

- 😀 The 'Set' instruction in PLC programming is used to activate outputs, such as turning on a motor.

- 😀 The 'Reset' instruction is used to deactivate outputs, like turning off a motor.

- 😀 Logic instructions like 'AND' and 'OR' are used to check whether multiple inputs meet certain conditions, like verifying a temperature and an oven door's status.

- 😀 The 'Counter' instruction in PLC can count the number of products passing through an assembly line, which helps track production.

- 😀 PID control is used in industrial systems for regulating processes like temperature, pressure, and flow, providing accuracy and stability for various processes.

Q & A

What is the main goal of PLC programming in industrial automation?

-The main goal of PLC programming in industrial automation is to enable students to design, develop, and implement PLC programs in various automation scenarios, focusing on control systems, optimization, and improving efficiency.

What are the core topics covered in PLC programming education?

-PLC programming education covers topics such as PLC programming structure, basic programming instructions, advanced techniques, logic functions like timers and counters, and control methods like PID (Proportional, Integral, Derivative).

What are the basic PLC instructions used for controlling outputs?

-Basic PLC instructions used to control outputs include 'Set' (to turn on an output), 'Reset' (to turn off an output), 'AND' (to check if two or more inputs are true), 'OR' (to check if two or more inputs are false), 'NOT' (to invert an input value), 'Timer' (to delay execution), and 'Counter' (to count pulses).

How does a timer instruction work in a PLC program?

-A timer instruction in a PLC program is used to delay the execution of the next instruction for a specified period, allowing for controlled time-based operations in automation processes.

What is the role of a counter instruction in PLC programming?

-A counter instruction is used to count the number of pulses received by the PLC input, which can be utilized in applications like counting products on an assembly line or measuring repetitive actions.

Can you explain the concept of PID control in industrial automation?

-PID control is a method used in industrial automation to regulate system variables such as temperature, pressure, or flow. It involves three types of feedback: Proportional (P), Integral (I), and Derivative (D) to adjust the output based on system errors and changes.

What are the key differences between PLC and PID control systems?

-PLC (Programmable Logic Controller) is a physical platform that executes control logic, while PID control is a method used to adjust variables in the system. PID can be programmed into a PLC to manage processes like temperature or pressure control.

What are the advantages of using PID control in industrial systems?

-PID control provides high accuracy, stability, and versatility in regulating various industrial processes like temperature, pressure, and flow. It helps maintain the system close to desired setpoints with minimal error.

What are some disadvantages of PID control?

-Some disadvantages of PID control include its complexity in design and implementation, sensitivity to disturbances, and the potential need for significant resources, such as computational power and tuning efforts.

How does the Proportional feedback in PID control work?

-In Proportional feedback, the error between the desired and actual values is measured and multiplied by a proportional constant to produce a control signal. This signal is used to move the system toward the desired value, with the size of the correction directly related to the magnitude of the error.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Penjelasan Tugas Kelompok

Belajar PLC | Pengenalan Programmable Logic Controller #1

Automation engineer कैसे बने ? After Mechanical, Electrical & ECE engg.| High salary engineering Job

What is Process Automation?

Praktik 9.1. PLC Pneumatic Instalasi dan Transfer program

Pressure Sensor, Transducer, and Transmitter Explained | Application of Each

5.0 / 5 (0 votes)