Fan Bearing Differences: Fluid Dynamic, Ball, Hydro Dynamic, & Sleeve Explained, ft. Noctua

Summary

TLDRIn this video, Jacob from Nocta dives into the complexities of fan bearings, challenging the oversimplified marketing hierarchy that places FDB bearings at the top. While ball bearings are often seen as the best, the choice of bearing depends on factors like temperature stability, load capacity, and acoustic performance. Jacob explains the technical aspects of different bearing types, such as sleeve bearings and FDB, shedding light on the myths surrounding them. He emphasizes the importance of manufacturer reputation and the multitude of factors affecting bearing quality, advising consumers not to get fixated on the label but to consider real-world performance and longevity.

Takeaways

- 😀 FDB bearings and hydrodynamic bearings are essentially the same, with both relying on fluid dynamics to create a pressure field, but marketing often complicates the terminology.

- 😀 The 'Herring bone' groove design in bearings, commonly associated with FDB, is just one type of grooved bearing, and it's not always superior for fan applications.

- 😀 Ball bearings are better for higher temperature and load-bearing situations (such as industrial use) due to their superior performance in these environments, but they can be louder than other types.

- 😀 Sleeve bearings (including FDB and hydrodynamic) work well for lower temperatures and are quieter but less durable under high load and temperature conditions compared to ball bearings.

- 😀 The structure and quality of the bearing’s components, such as surface finish, tolerances, and material compatibility, play a more significant role in bearing performance than simply the bearing type.

- 😀 Acoustic performance, load capacity, and temperature stability are key factors to consider when selecting bearings for computer fans, as well as the anticipated lifetime and maintenance needs.

- 😀 Bearing failure can be caused by a range of factors, including lubricant compatibility and the precision of the bearing components, not just the bearing type itself.

- 😀 In high RPM fans (like large 200mm fans), increasing the shaft diameter and selecting the right bearing type is critical to ensuring stability and longevity.

- 😀 The common marketing of FDB bearings on fan packaging can be misleading, as the actual bearing quality depends on much more than just the type (e.g., sleeve vs. ball).

- 😀 It’s crucial to consider a manufacturer’s track record rather than relying solely on the bearing type label when evaluating the quality of a fan's bearing system.

Q & A

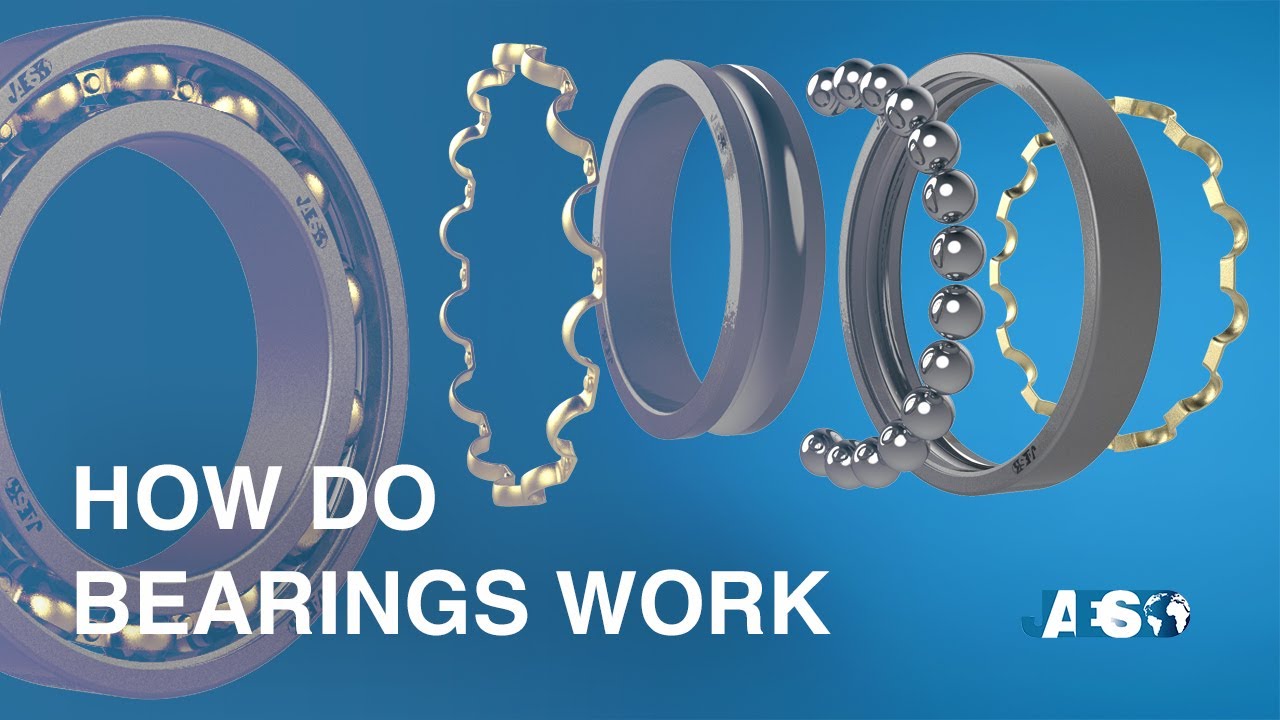

What is the key difference between ball bearings, sleeve bearings, and FDB bearings in computer fans?

-Ball bearings are often used for high load capacity and better temperature stability but can be noisier. Sleeve bearings are simpler and quieter but may not handle higher loads or temperatures as well. FDB (Fluid Dynamic Bearings) and HDB (Hydrodynamic Bearings) are terms that generally refer to a dynamic fluid pressure system inside a lubricated sleeve bearing, often with additional grooves like herringbone or spiral patterns for better fluid circulation.

Why is there confusion between FDB and HDB bearings in fan marketing?

-FDB and HDB are essentially interchangeable terms, both referring to bearings that use fluid pressure to reduce friction. The confusion arises from marketing, as companies sometimes create distinctions that are not necessarily based on technical differences but rather on branding or slight design variations, such as grooves for fluid circulation.

How does fluid circulation affect bearing performance in fans?

-Grooves in FDB and HDB bearings enhance the circulation of lubricants, which helps create dynamic pressure fields. This reduces friction and wear, particularly in higher load or temperature environments. However, the presence of grooves doesn't always guarantee better performance, as it depends on the application and the bearing's design.

What are the primary factors that influence bearing selection in computer fans?

-The main factors include temperature stability, lifetime, load-bearing capacity, and acoustics. The expected temperature range, operating conditions (e.g., high load or RPM), and noise levels are critical in choosing the appropriate bearing type.

Why is bearing life important when selecting a fan?

-Bearing life is a key determinant of a fan's durability and overall performance. Bearings directly impact how long a fan will operate effectively, especially under continuous use in environments with varying temperatures and loads. A high-quality bearing will ensure quieter and longer-lasting fan performance.

How do high temperatures affect bearing performance?

-High temperatures can degrade the performance of some bearings, particularly sleeve bearings, which are less effective at handling heat. FDB bearings, with their enhanced fluid circulation through grooves, are better suited to handle higher temperatures and can support higher viscosity lubricants that resist dissipation in heat.

What is the significance of the 'groove' in FDB and HDB bearings?

-The groove in these bearings helps to improve the lubrication efficiency by facilitating fluid circulation. This leads to better fluid retention and creates a dynamic pressure field, reducing friction and wear. However, the groove's effectiveness depends on the design and how well it is manufactured.

Why are ball bearings chosen for higher RPM and load-bearing applications?

-Ball bearings excel in applications requiring high load capacity and faster speeds, such as industrial or high-performance fans. They are durable, can handle higher RPMs, and provide better stability under load, though they tend to produce more noise compared to sleeve or FDB bearings.

How do fan manufacturers determine which bearing to use in different models?

-Manufacturers consider factors like fan size, RPM, operating temperature, and load-bearing requirements when selecting bearings. For high RPM or large fans, such as 200mm models, manufacturers may opt for ball bearings due to their superior load-bearing capabilities. For quieter, low-heat applications, sleeve or FDB bearings may be used.

What is the potential downside of using FDB or HDB bearings?

-One downside is that the grooves in FDB or HDB bearings can add complexity to the manufacturing process. If the grooves are poorly designed or rough, they can introduce noise. Additionally, FDB bearings may not be necessary for all applications, especially where the load and temperature are not extreme.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

How do ball and roller bearings work? Types and durability calculation. DIN ISO 281

Introduction to Bearings

How to Find Back Bearing from Fore Bearing ( WCB & RB )

Map Skills - Calculating Bearings in a Geography Examination

Gear Forces and Power Transmission of SPUR GEARS in Just Over 12 Minutes!

Bearings - Corbettmaths

5.0 / 5 (0 votes)