Melakukan Pekerjaan dengan Mesin Gerinda

Summary

TLDRThis video script provides a comprehensive guide on operating a grinding machine, explaining its functionality and the precise steps required for grinding workpieces with high accuracy. It details the preparation process, such as setting up the machine, using safety gear, and adjusting the grinding wheel. The script outlines the process for grinding different surfaces, adjusting speed and movement, and ensuring a high level of precision. It also includes post-grinding steps like measuring and checking the surface roughness of the workpiece. The entire process is demonstrated with careful attention to safety and machine settings, ensuring an efficient and accurate operation.

Takeaways

- 😀 The grinding machine is a tool used to shape or cut workpieces with high precision, often for metal surfaces.

- 😀 Grinding machines can quickly and accurately grind hardened materials that other machines cannot handle.

- 😀 The working principle of the grinding machine involves a rotating grinding wheel that comes into contact with the workpiece, removing material to achieve the desired shape or sharpness.

- 😀 Proper personal protective equipment (PPE) such as wearpacks, masks, and safety glasses is essential when operating the grinding machine.

- 😀 The grinding wheel should be carefully positioned and its rotation activated before starting the grinding process.

- 😀 Coolant should be activated to reduce heat and improve cutting performance during grinding.

- 😀 The workpiece must be securely placed on the magnetic table and aligned before beginning the grinding process.

- 😀 During grinding, the machine's automatic feed system can be used to adjust the workpiece's position in both the longitudinal and cross directions.

- 😀 After grinding a surface, the workpiece should be checked for surface roughness using a roughness tester to ensure quality.

- 😀 Once the grinding process is completed, the workpiece should be removed from the machine, and any sharp edges should be smoothed using a file.

- 😀 It's important to measure the workpiece with a micrometer after grinding to ensure accuracy and meet specifications.

Q & A

What is the purpose of a grinding machine?

-A grinding machine is used to grind or cut workpieces with the goal of quickly removing material from the surface of metals, providing high accuracy and achieving the desired shape.

How does the grinding machine work?

-The grinding machine works by rotating a grinding wheel that comes into contact with the workpiece, causing abrasion, sharpening, or cutting to remove excess material.

What makes the grinding machine different from other types of machinery?

-The grinding machine is capable of working on hardened materials that cannot be processed by other tools, providing high speed and precision.

What is an outside micrometer used for in the grinding process?

-An outside micrometer is used to measure the workpiece's dimensions with high accuracy, typically to a thousandth of a millimeter.

What safety equipment should be worn when operating a grinding machine?

-When operating a grinding machine, operators should wear protective equipment such as a wearpack, a mask, and safety goggles.

What is the function of the oil pump in the grinding machine operation?

-The oil pump is turned on for 1-2 minutes to ensure proper lubrication and cooling of the grinding wheel and workpiece during operation.

How is the grinding wheel positioned for effective grinding?

-The dresser is positioned at the center of the grinding wheel, then lowered to touch the wheel. The cooling system is activated to prevent overheating during grinding.

What role does the magnetic chuck play in the grinding process?

-The magnetic chuck holds the workpiece securely in place during the grinding process by using a magnetic field, which ensures precision and stability.

What steps are involved in grinding a workpiece to achieve the desired surface finish?

-The workpiece is first secured on the magnetic chuck, and the grinding wheel is positioned to touch the surface. The grinding process is performed in multiple steps, adjusting the movement and pressure of the grinding wheel to achieve the desired surface roughness.

How do you check the finished product for accuracy after grinding?

-After grinding, the workpiece is measured using a micrometer for dimensional accuracy, and the surface roughness is checked using a rugotest instrument to ensure it meets the required standards.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

SURFACE GRINDING PERFECT #wokochannel #pedaganglucu #tukangteknik

All Lathe Machine Operations: Turning, Facing, Taper Turning, Boring, Knurling, Tapping, Forming

How to make Surgical Instruments {www downloadshiva com}

Best Tips and Methods for world 2 in ANIME LAST STAND

CARA MEMBUAT ESPRESSO YANG PROPER UNTUK KOPI SUSU GULA AREN

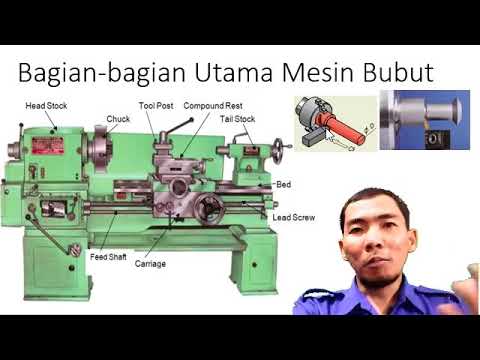

Bagian - bagian utama Mesin Bubut

5.0 / 5 (0 votes)